Biodiesel Production Equipment

Find innovative production technology for making biodiesel and connect directly with world-leading specialists

The waste oils from cooking in your kitchen could be transformed to biodiesel. Oily biomass such as soybean, animal fats, or recycled grease make excellent feedstocks to produce high quality alternative transport fuel. Materials are combined with an alcohol in a transesterification reactor that converts the mass into crude biodiesel. The finished product is a low-sulfur, biodegradable fuel that can be used in its pure formulation or in petroleum diesel fuel blends.

Technology picks for biodiesel processing

Biodiesel distillation process

In the biodiesel production industry, achieving high-quality fuel often requires additional r...

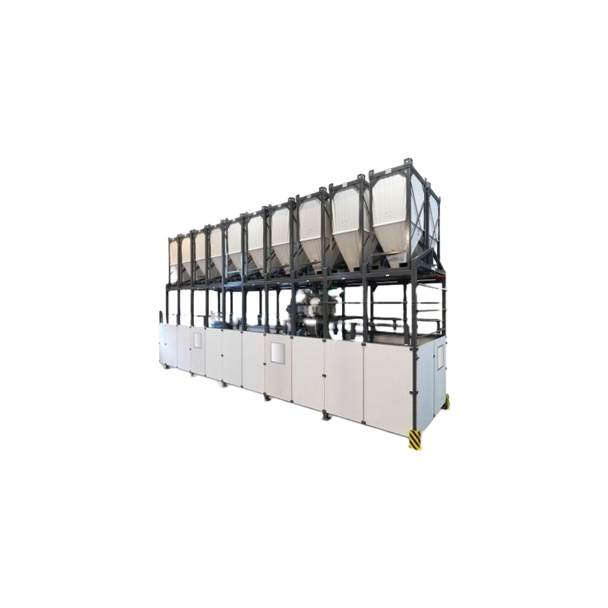

Biodiesel pretreatment system

In the biodiesel production industry, one of the key challenges faced is ensuring the feedstoc...

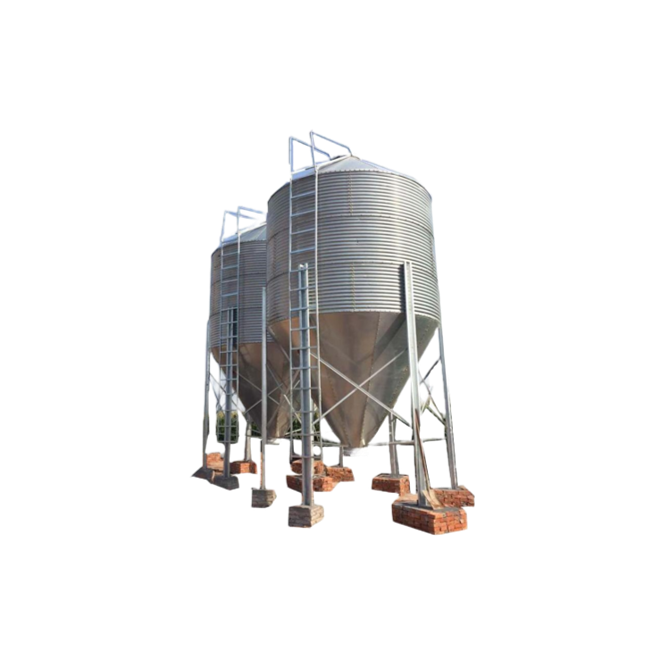

Production plant for biodiesel

As a biofuel producer, making biodiesel from several types of treated vegetable oils or anima...

Glycerine manufacturing plant

Glycerol or glycerin is the major by-product generated in the biodiesel production process. Bu...

Select your biodiesel process

Tell us about your production challenge

Processing equipment to convert raw biodiesel into the finished product

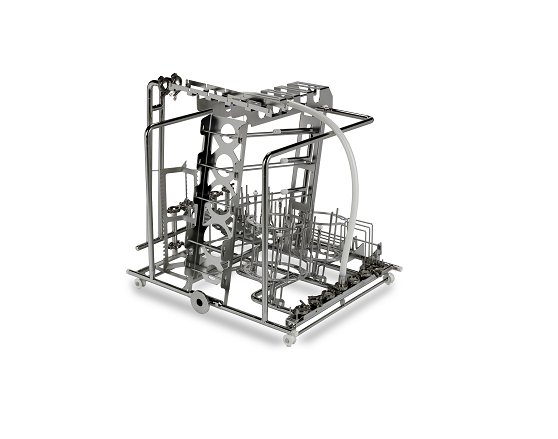

The transformation of organic waste into biofuel starts in the sanitization machine that deacidifies your base feedstock and degums it from wax content. This is when your biomaterial is ready to be pumped to the transesterification reactor and transformed into unrefined biodiesel.

This chemical process forms glycerin that you then need to separate from the fuel using a centrifuge. The remaining liquid passes through a filtration system, leaving you with upgraded biodiesel at the other end.

Diesel blends raise the emissions bar

Biodiesel offers a range of advantages over standard diesel. Besides being a renewable fuel, it emits lower levels of toxics and contaminants. And, unlike diesel, it does not spout any sulfur dioxide.

Although pure biodiesel can be used with existing technologies, it is more widely used in concentrations with regular diesel. Most products on the market contain either a maximum of 5% biodiesel (B5) or up to 20% (B20).

Biodiesel gets the green light

Large vehicles like trucks, buses, and trains usually rely on diesel engines. Thus, making biodiesel processing a central plank of strategies to reduce greenhouse gas emissions in the transportation sector.

Oil-bearing biomass is being used in the same way to develop alternatives to fossil jet kerosene. Sustainable Aviation Fuel (SAF) is projected to increase from 5% of the global jet fuel mix in the early 2020s to almost 20% by 2040.

Processing steps involved in biodiesel making

Which biodiesel technology do you need?

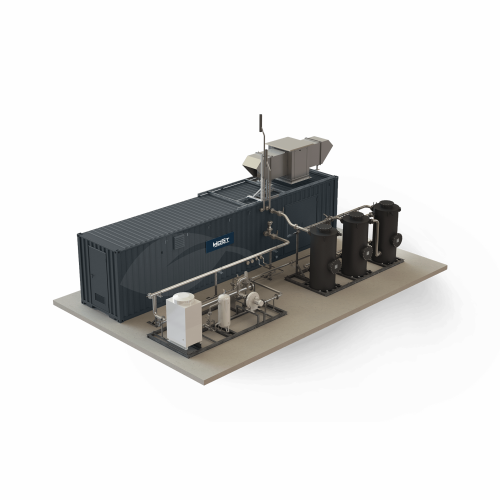

Biogas upgrader for high methane yield

Biogas plants producing raw biogas often face the challenge of maximizing the methan...

Biomass baler for woody biomass collection

In vegetation management, handling woody biomass often involves traditional chi...

Biodiesel distillation process

In the biodiesel production industry, achieving high-quality fuel often requires additional r...

Biodiesel pretreatment system

In the biodiesel production industry, one of the key challenges faced is ensuring the feedstoc...

Synthesis gas cooler for partial oxidation of oil or natural gas

In high-temperature processes like the non-catalytic cr...

Industrial homogenizer for food and beverage applications

In the production of food and beverage products, maintaining a...

Biomass drying solution

In the biomass industry, various drying methods struggle to efficiently handle large particles like w...

Manure treatment system for livestock breeding

In livestock breeding, managing and treating manure effectively is essentia...

Biogas plant screw press separators

In biogas plants, efficient separation of solid and liquid phases from digestate is cru...

Agitator bead mill reactor for molecular synthesis by mechanochemistry in continuous flow

To achieve cleaner, safer,...

Production plant for biodiesel

As a biofuel producer, making biodiesel from several types of treated vegetable oils or anima...

Glycerine manufacturing plant

Glycerol or glycerin is the major by-product generated in the biodiesel production process. Bu...

Water oil separation centrifuge

Some industries, such as petrochemical, generate large volumes of oily wastewater due to the...

Industrial liquid filtration system

Systems for the filtration of liquids with suspended solid contents can be challenging ...

Industrial leaf filter for chemicals

In recent years the removal of sulphur has received increasing attention because of sa...

Advanced anaerobic digestion with external separation

Factories of dairy products, palm and coconut oil, slaughterhouses,...

Waste to energy anaerobic digestion system

The food industry produces tremendous amounts of waste at food production facil...

Anaerobic UASB wastewater treatment

If you need to remove organic compounds from your wastewater, the up-flow anaerobic slu...

Top loading arm

Load or unload liquids from the top of the tanks safely and securely for trucks, railcars, small or big contai...

Folding stairs and safety cages

To ensure the safety of operator while working between a loading platform and road or rail t...

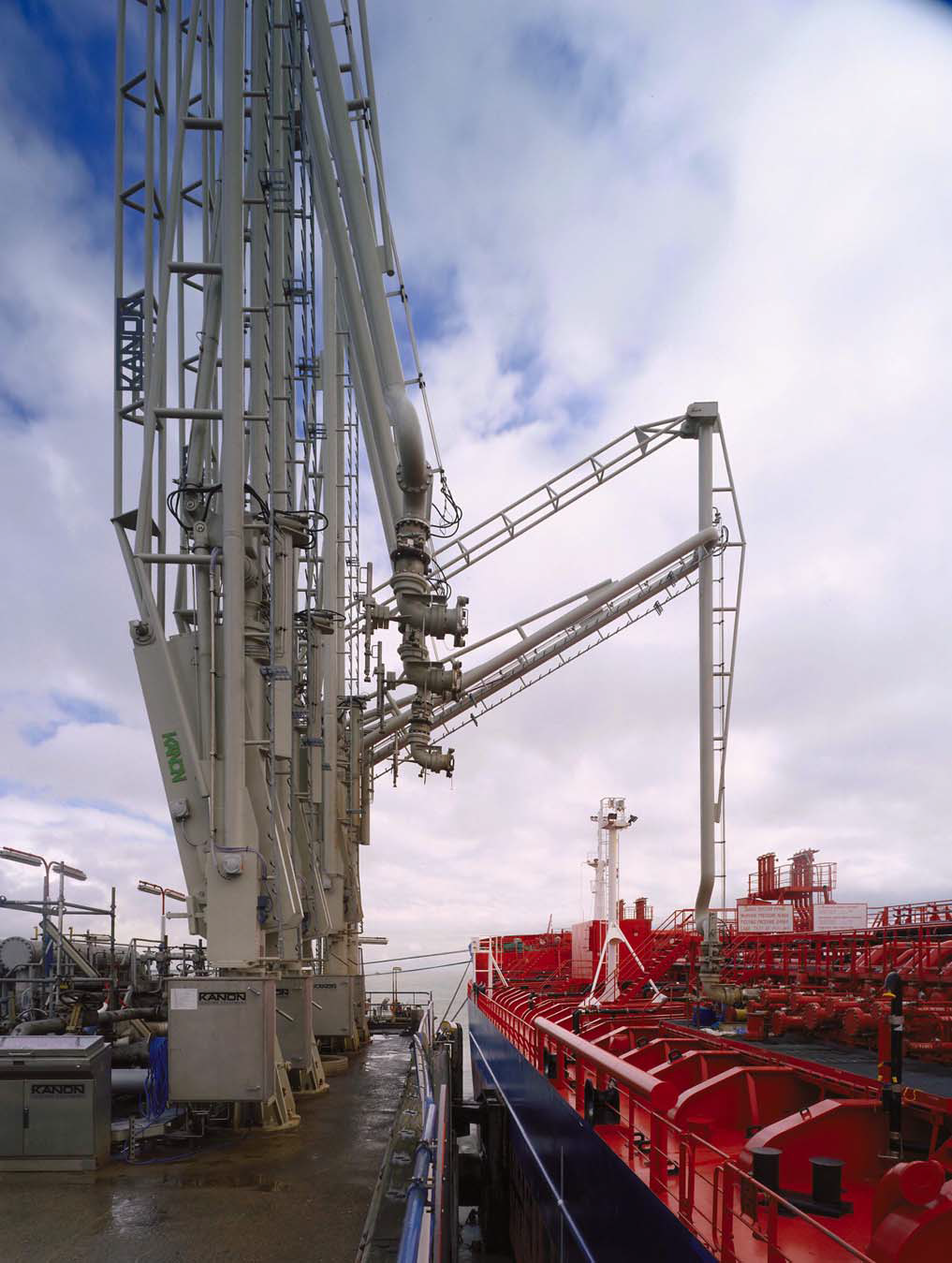

Marine loading arm

A hose or loading arm is needed when you load or unload fluids from a ship or transfer fluids between vess...

Bottom loading arm

Bottom loading/unloading arms are designed to be connected on the side or on the rear of the tanker and so...

Vertical pressure leaf filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to many in...

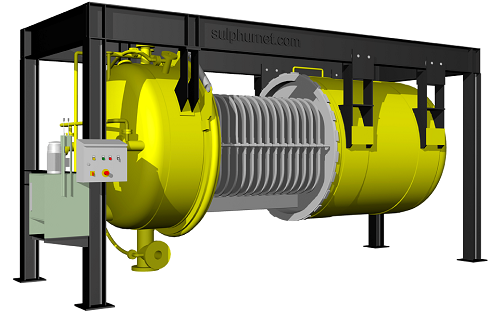

Horizontal pressure leaf filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to many ...

Horizontal plate scavenger filters

Reliable and low maintenance filtration of fluids with high dirt load is essential to ma...

Filter pressure leaf

From chemical processing, to energy production, to edible oils production, product quality is often depe...