Biogas Production Equipment

Find innovative production technology for making biogas and connect directly with world-leading specialists

As an alternative to conventional fuels, biogas is produced from the processing of biomass resources as an industrial feedstock. Biogas is a renewable and local energy source that contributes to sustainable heat and power production. Besides making use of agricultural wastes such as crop and forest residues and animal manure, biogas production converts organic wastes from industrial and municipal waste to energy. This is usually achieved by implementing the anaerobic digestion process in biogas plants.

Technology picks for biogas processing

Tell us about your production challenge

Anaerobic digestion is a process of decomposition of organic material in the absence of oxygen. During anaerobic fermentation of organic matter, the feedstock material breaks and degrades; in the meanwhile, different bacteria populations generate biogas. The produced biogas is in general a mixture of mostly methane, carbon dioxide, nitrogen, hydrogen, oxygen, and water vapor. The high concentration of methane in biogas indicates its potential to be injected into existing gas grids thanks to equipment for biogas purification and upgrading technology.

Upgrading biogas to biomethane

When biogas comes out from the digestion tanks, is a mixture of methane, carbon dioxide, hydrogen sulfide, air, hydrogen, Volatile Organic Components (VOCs), and siloxanes. Upgrading or purifying biogas means removing any CO2 and other contaminants present in biogas to produce biomethane.

In the membrane separation process, biogas produced in an anaerobic digestion plant enters the installation and is cooled and dehumidified. It is then transported to the active carbon filter system where it is purified by removing hydrogen sulfide and other contaminants. Once cleaned, the gas is compressed to the required pressure. The biogas flows to the membrane system in which methane is separated from carbon dioxide. The actual separation takes place because CO2 diffuses more easily than methane through the membrane straws, leading to separation.

Anaerobic digestion

Anaerobic digestion is the process through which organic matter is broken down in an oxygen-free environment to create biogas. Therefore, biogas is created by food waste, wastewater, animal manure, and various other organic wastes and is used to generate electricity and to provide heat.

When organic waste arrives at the plant, it is pre-treated and mixed with liquid waste to create a slurry. Then, it is fed into the digestion tank where there is no oxygen. Bacteria within this slurry eat organic matter. As they eat and break down organic matter, they create biogas (methane, carbon dioxide, and other gases). Gas flows at the top of the tank and is captured to create electricity and heat. Methane can also be cleaned up and used as vehicle fuel. The remaining slurry can be collected to act as manure for plants.

Convert waste to energy

Biogas is considered a solution to biomass and sustainability. The basic form of biomass comes mainly from firewood, charcoal, and crop residues, which is commonly used in the combustion process of dry raw materials to generate heat and power. However, biogas production through anaerobic digestion reduces greenhouse gas emissions. And, it is widely used for the valorization of wet residues and liquid effluents, such as municipal wastes and sewage, and moist residues of agricultural crops and animal wastes. Biogas production technology allows for waste conversion of solids content into gaseous fuels. It is an environmentally friendly, renewable, clean biofuel. Biogas technology is also a source of nutrient-rich organic fertilizer.

Upgrading biogas to produce biomethane can help to fully utilize the potential of biogas as a vehicle fuel or as a substitute for natural gas. Therefore, it is important to improve the quality of the raw biogas to separate unwanted substances such as nitrogen, hydrogen, oxygen, and water. Finally, by removing carbon dioxide in the biogas upgrading process, the energy content of the gas is increased, making it ready for grid injection. The removed carbon dioxide can be recovered and stored for other industrial use.

Biogas Production Videos

Wastewater treatment

Biogas upgrading

Processing steps involved in biogas making

Which biogas technology do you need?

Gas contactor for hydrogen sulfide removal from biogas and sour gas

Managing hydrogen sulfide (H2S) in biogas from anae...

Manure biogas plant for agricultural sector

Agricultural businesses looking to enhance sustainability and generate additio...

Organic waste biogas plant

Industries handling large amounts of organic waste often struggle with inefficient waste manageme...

Biogas upgrader for high methane yield

Biogas plants producing raw biogas often face the challenge of maximizing the methan...

Agitator for biogas digesters in anaerobic digestion

In anaerobic digestion systems, achieving optimal mixing is crucial ...

Biomass baler for woody biomass collection

In vegetation management, handling woody biomass often involves traditional chi...

Microalgae photobioreactors for bioenergy production

In the pursuit of sustainable energy solutions, bioenergy derived fr...

Synthesis gas cooler for partial oxidation of oil or natural gas

In high-temperature processes like the non-catalytic cr...

Carbon capture membranes for Co2 separation

Industries seeking to minimize their CO2 footprint need efficient methods for ...

Biomass drying solution

In the biomass industry, various drying methods struggle to efficiently handle large particles like w...

Manure treatment system for livestock breeding

In livestock breeding, managing and treating manure effectively is essentia...

Biogas plant screw press separators

In biogas plants, efficient separation of solid and liquid phases from digestate is cru...

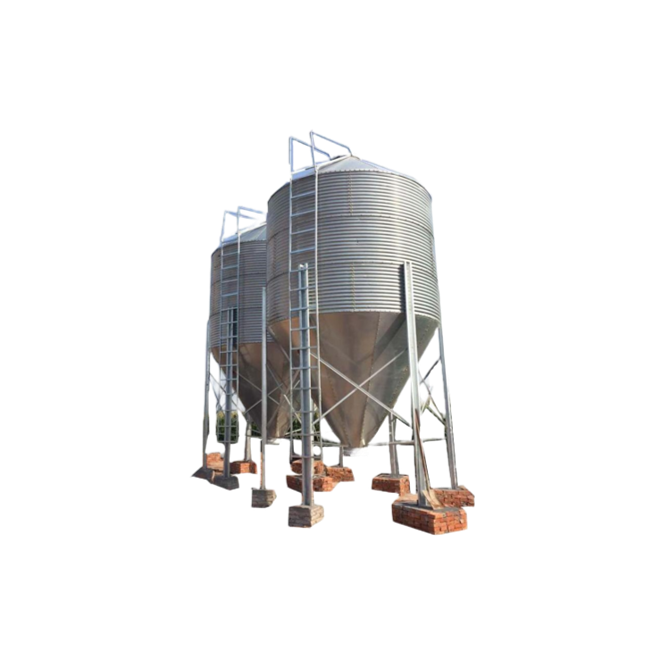

Biomass digester feeding system

In biogas production plants, efficiently transporting bulk biomass into the digester can be ...

Bulk biomass digester feeding system

In biogas production, efficiently transferring biomass from storage to the digester is...

Submersible chopper pump for manure treatment

In agricultural and biogas plants, handling slurry from animal husbandry can...

Submersible chopper pump for biogas plants

Effective slurry management in biogas plants often requires equipment capable o...

Heavy-duty submersible chopper pumps for manure treatment

In livestock farming and biogas facilities, dealing with long-...

Heavy-duty submersible chopper pump for biogas plants

In biogas plants and livestock farms, managing solid waste with lon...

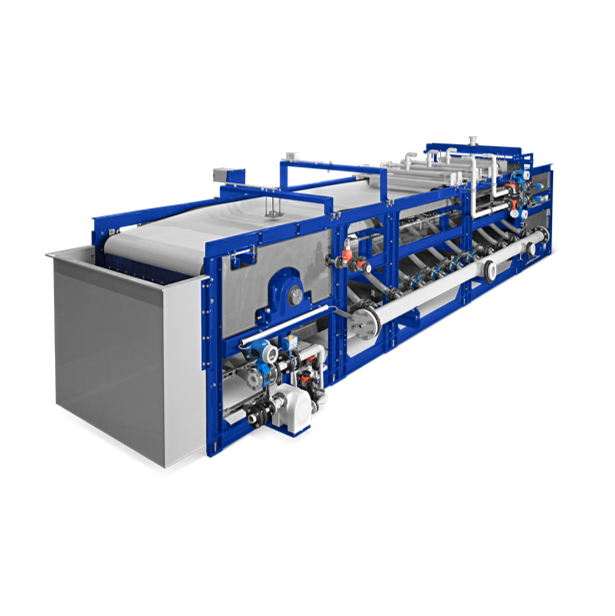

Horizontal screw press separator for biogas plants

In biogas plants, managing the efficient separation of solids and liqu...

Pulp and paper horizontal screw press separator

In pulp and paper recycling, achieving high-efficiency separation of solid...

Tapioca horizontal screw press separator for biogas plants

In biogas plants and industrial processes, managing waste mat...

Vertical screw separator for slurries

In the processing of slurries from biogas plants, livestock manure, and industrial wa...

Biogas digestate screw press separator

In biogas plants, managing the digestate effectively is crucial. The challenge lies ...

Horizontal screw press separator for biogas digestate treatment

In biogas plants, efficient separation of solids and liq...

Screw press separator for biogas digestate treatment

In biogas plants, managing the digestate efficiently is crucial to e...

Horizontal screw press separators for biogas plants

In biogas plant operations, efficiently separating the solid and liqu...

Wet spent grains pre-dewatering system

In brewing operations, managing the moisture content of wet spent grains is crucial....

Hybrid dryer for agriculture and industrial applications

In many sectors, including agriculture and the timber industry, ...

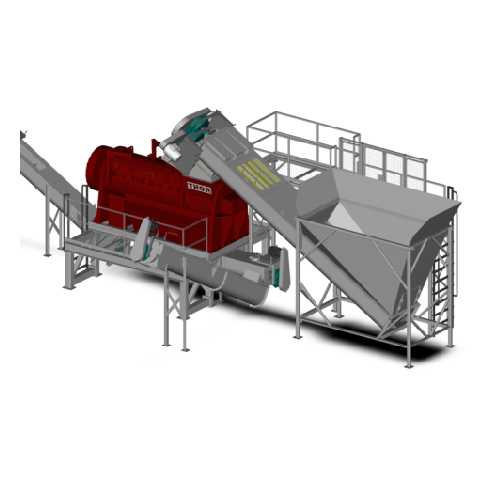

Organic material extraction for recycling

In waste recycling, separating organic materials from packaging can be challengi...

Exergy pressurized superheated steam dryer

Traditional dryers and heat transfer systems, like belt-, drum- or bed dryers a...

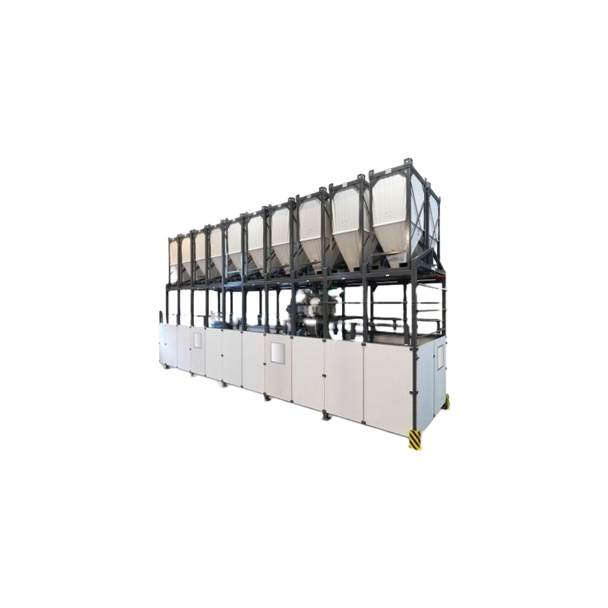

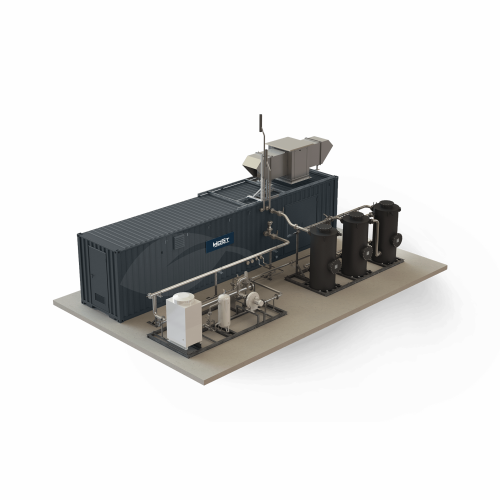

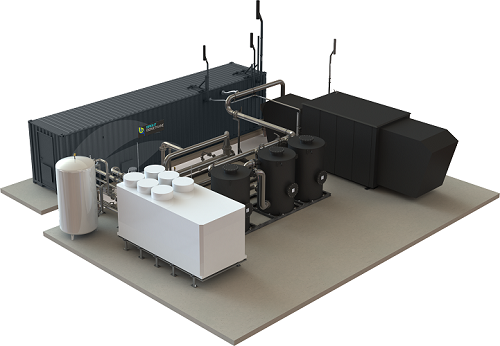

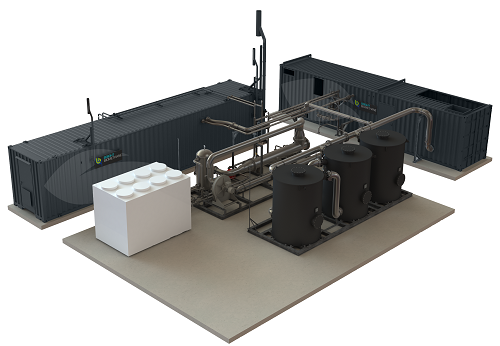

Efficient sized biomethane production system

Also referred to as biogas purification, biogas upgrading is an excellent alt...

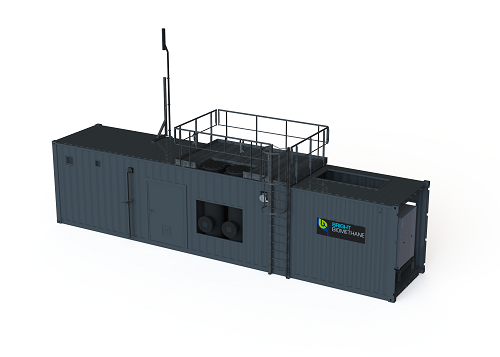

Large-scale biomethane production system

Membrane separation technology for biogas purification is considered as an effecti...

Modular biogas to biomethane system

The primary purpose of biogas upgrading technology is to increase the volumetric energy...

Small-scale biogas upgrading system

Biogas upgrading refers to the process of purifying biogas through separating methane f...

Belt dryer for sewage sludge

If your water treatment plant often facing difficulties with sewage sludge deposits, drying the...

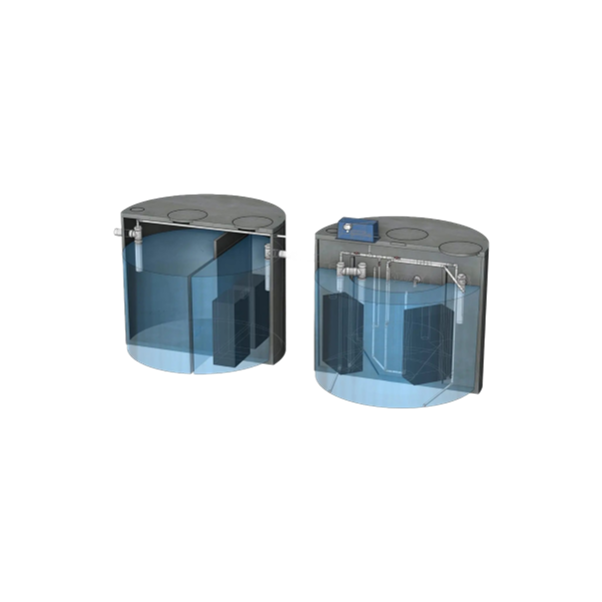

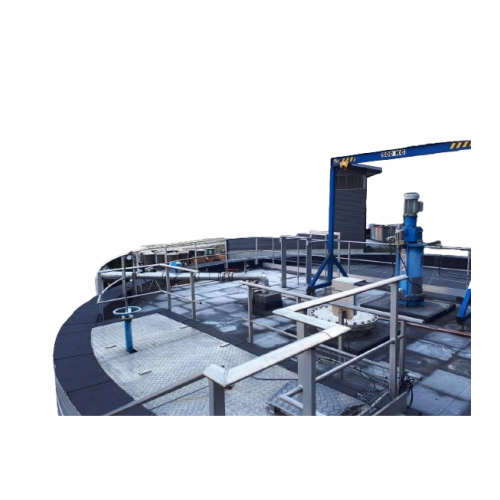

Advanced anaerobic digestion with external separation

Factories of dairy products, palm and coconut oil, slaughterhouses,...

Waste to energy anaerobic digestion system

The food industry produces tremendous amounts of waste at food production facil...

Anaerobic EGSB wastewater treatment

If you are looking for a compact and sustainable solution to remove organic pollution f...

Biogas heating system

Traditionally, heating of wastewater would use boilers and heat exchangers. Biogas is a natural by-prod...

Anaerobic UASB wastewater treatment

If you need to remove organic compounds from your wastewater, the up-flow anaerobic slu...

Biological H2S scrubber

Raw biogas produced by digestion, for example during an anaerobic process is approximately 60% methan...

H2S scrubber for biogas

Raw biogas produced by digestion, for example during an anaerobic process is approximately 60% methan...