Making Calcium Carbonate

Find innovative production technology for making calcium carbonate and connect directly with world-leading specialists

Calcium carbonate makes up almost one-twentieth of the earth’s crust. But the abundant mineral is found in many living things, including the human body. However, processing calcium carbonate extracts the multi-purpose material from inorganic sediments, namely limestone, chalk, and marble.

Stories about calcium carbonate

Select your calcium carbonate process

Tell us about your production challenge

Use a rotary kiln calcium carbonate processing of limestone stock smaller than 40 millimeters

Limestone is subjected to high temperatures to strip carbon dioxide and produce calcium oxide. This calcination process is performed in a kiln, but the type of technology depends on the feed size of your raw material.

A shaft kiln typically handles limestone between 20 mm and 175 mm in size. Stones go through preheating, heating, and cooling as they travel down the shaft to discharge quicklime. A rotary kiln employs the same principle but is set at a horizontal position and tipped at an angle of around 4°. This structure accommodates finer stones in the 15 mm to 40 mm range.

Mix calcium slurry constantly to avoid crystallization of particles

Calcium oxide is hydrated to produce calcium hydroxide. Also known as slaked lime, this compound treats industrial wastewater and neutralizes gases.

Slaking temperature is critical to the structure of particles. If you heat the slurry to around the boiling point of water forms finer particles sizes with a smaller specific surface. But unless mixed well, the particles will crystallize and agglomerate in the slurry.

Precipitated calcium carbonate can achieve 99.9% purity

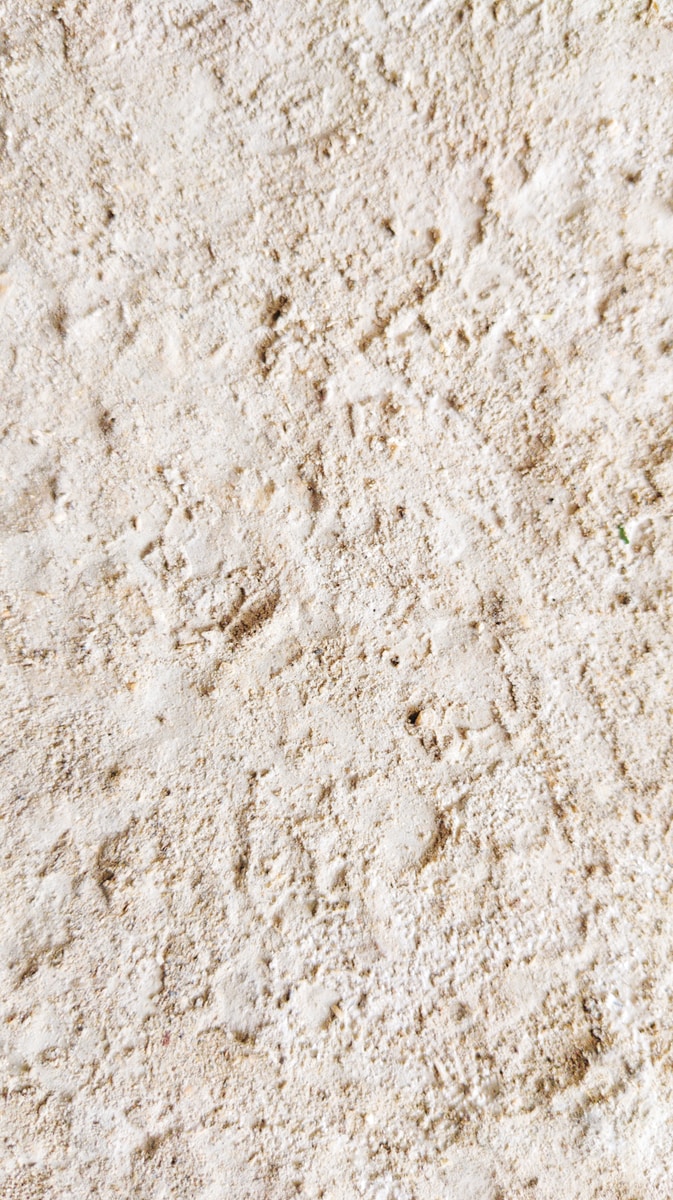

Precipitated calcium carbonate (PPC) is synthetically produced from the chemical reaction between carbon dioxide and “milk-of-lime” slurry. The material is a refined form of limestone using calcium carbonate processing techniques.

The white material serves as a filler in different applications such as paints, papers, and pharmaceutical products. The grain size can be controlled from submicron to more than 10 microns, and the purity can be increased to 99.9%.

Spongy form of calcium carbonate could open up new applications

Researchers stumbled upon a spongy form of calcium carbonate occurring naturally in mussels. Ground shells of the mollusc reacted to acetic acid to form a highly absorbent type of calcium carbonate.

The porous material can soak up contaminants like oils or dyes and is an object of interest for a range of biomedical applications.

Processing steps involved in calcium carbonate making

Which calcium carbonate technology do you need?

Sample divider for on-site reduction of bulk materials

Accurate sample analysis hinges on obtaining a representative and ...

Pendulum mill for fine grinding and drying

In industries where fine grinding and drying of soft to medium-hard materials i...

High pressure roller mill for medium-fine crushing

In various industrial sectors, especially chemicals and minerals proce...

Ultrafine classifier for precise particle separation

When processing fine powders, achieving consistent particle size dis...

Ultrafine classifier for soft to medium-hard mineral processing

In the industrial mineral processing sector, precision i...

Ultra-fine grinding with ball mills and agitated media mills

For industries manufacturing high-quality mineral powders o...

Ultrafine grinding mill for calcium carbonate slurries

In industrial applications, achieving ultrafine particle sizes in ...

Air classifier for classifying industrial minerals

In industries such as mining and chemical processing, precise particle...

Powder synthesis reactors for nanometer and micrometer particles

Industrial production of high-quality powder materials ...

Industrial ring dryers for high-capacity drying applications

In industries such as food processing, chemical manufacturi...

Bulk bag weighing system for batching operations

In industrial batching processes, precise weighing of minor ingredients i...

Dust-free big bag connection system for bulk solids

In industries handling bulk solids, managing dust during big bag conn...

Big bag loading station for bulk product handling

Handling large quantities of bulk products efficiently and safely is a ...

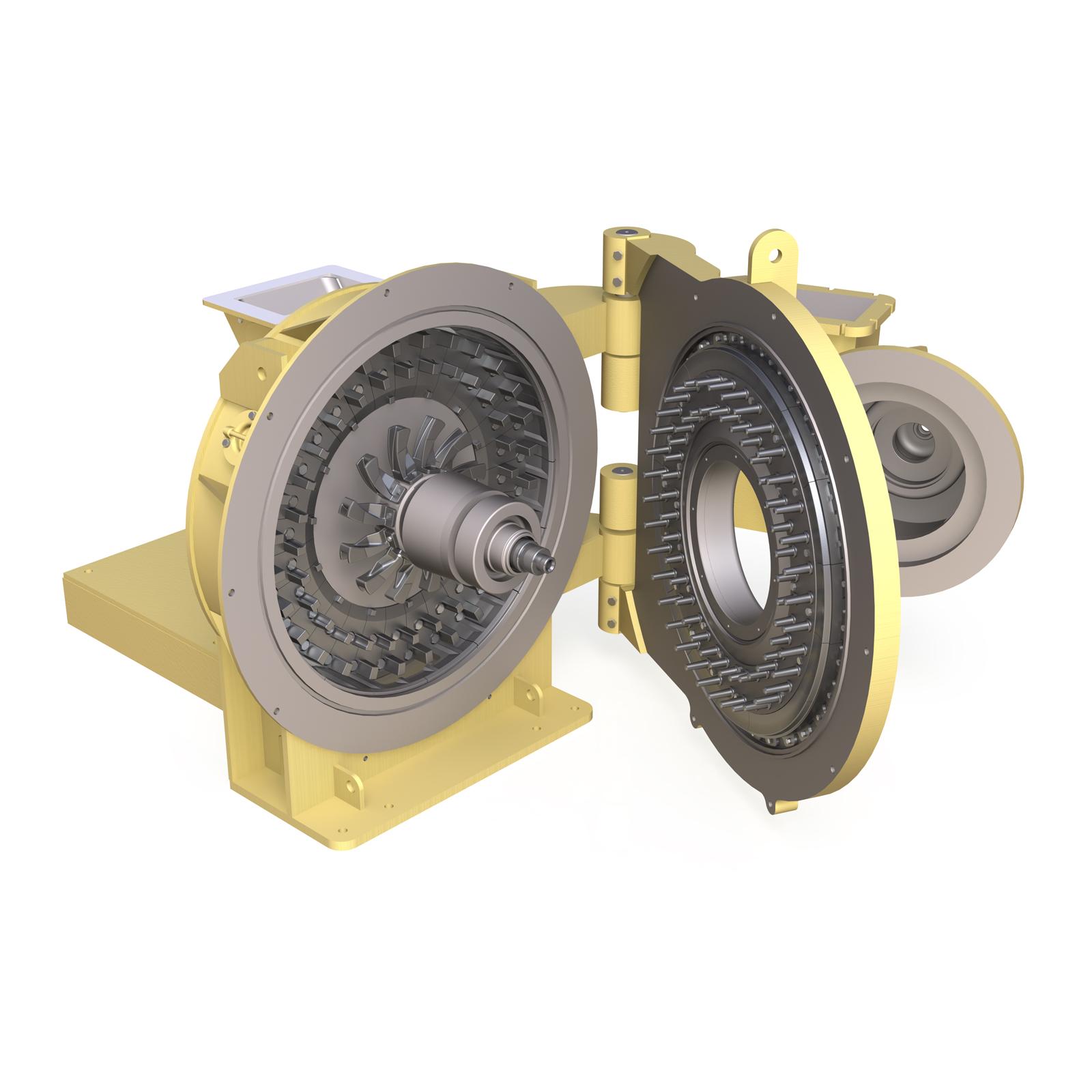

Chemical and mineral processing centrifuge

In chemical and mineral processing, achieving clear clarification and effective...

Tubular screw conveyor for powdery and granular materials

In many industries, transporting bulk powdery and granular mat...

High-temperature screw conveyors for bulk solids

In environments such as foundries, coal power stations, and drying plants...

External electric motovibrators for hazardous materials

In industrial settings where handling of bulk solids is necessary...

Aeration pads for powdery material flow in silos

In industries where the efficient discharge of powdery materials from sil...

Bulk reception solution for industrial material handling

In industrial settings, receiving bulk materials efficiently is ...

Agitator bead mill for flow chemistry

During the early stages of synthesis, generating only limited product quantities can ...

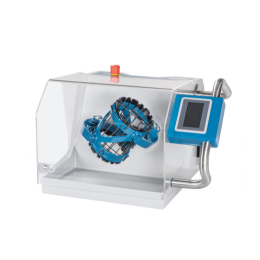

R&D shaker mixer for battery powders and chemicals

Material heterogeneity, agglomeration, and contamination are key param...

Grinding and drying of CaCO3

Widely used in the construction industry as filling materials, calcium carbonate is usually mad...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Simple valve sack packer

Sometimes in the packing process, product leaks out of the top of a bag that has just been filled. A...

Horizontal rotary ball mill drum

A horizontal rotary ball mill drum can be used for grinding of dry hard materials, such as ...

High volume particles separation sieve

For large scale production processes in the chemicals or food industries that requir...

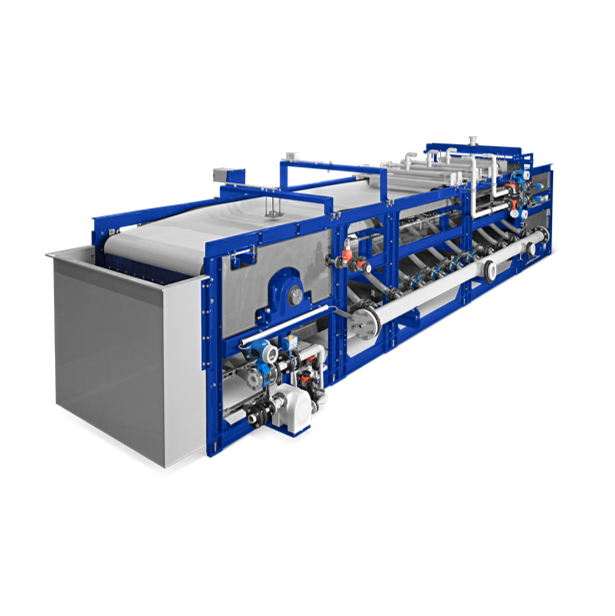

Belt filter press

When a saturated slurry or sludge must be dehydrated in a continuous process municipal waste water treatmen...

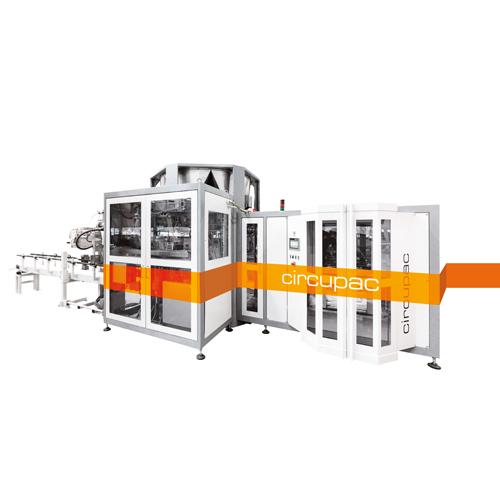

Rotary bag packers for valve bags

Quick filling of bags while avoiding leakage out of the top of a bag can be challenging o...

Big bag discharge system

Dust emissions, product loss and product contamination are the main risks when discharging products ...

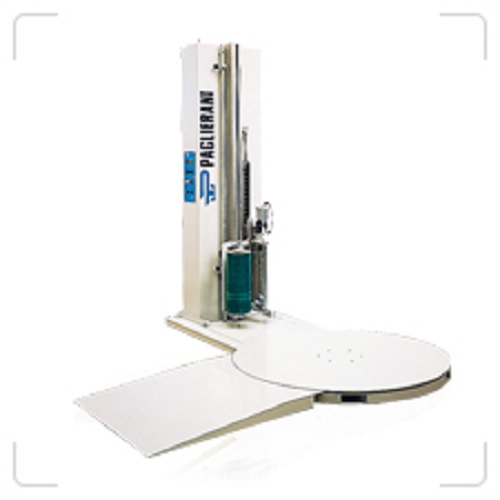

Semi-automatic stretch wrapping machine

At lower speeds, some level of automation is required to provide a cost-effective m...

Traditional palletizer for bags

Packaging lines may require a single, flexible solution that can handle many different palle...

Palletizing robot arm

For high speed palletizing, palletizing high payloads, or just where greater flexibility is required, i...

Inline batch mixer for solids and liquids

Several issues often arise when your process requires batch-wise mixing of powde...

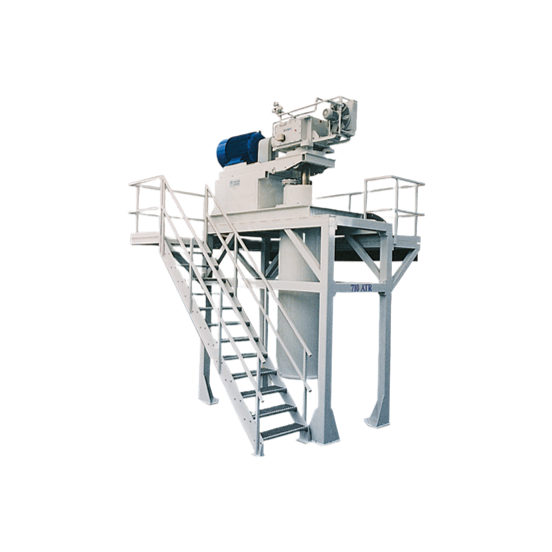

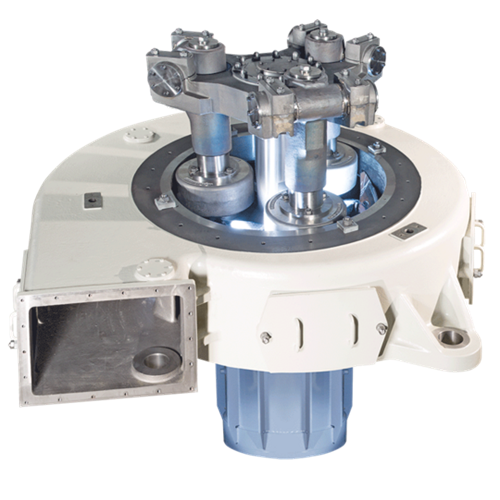

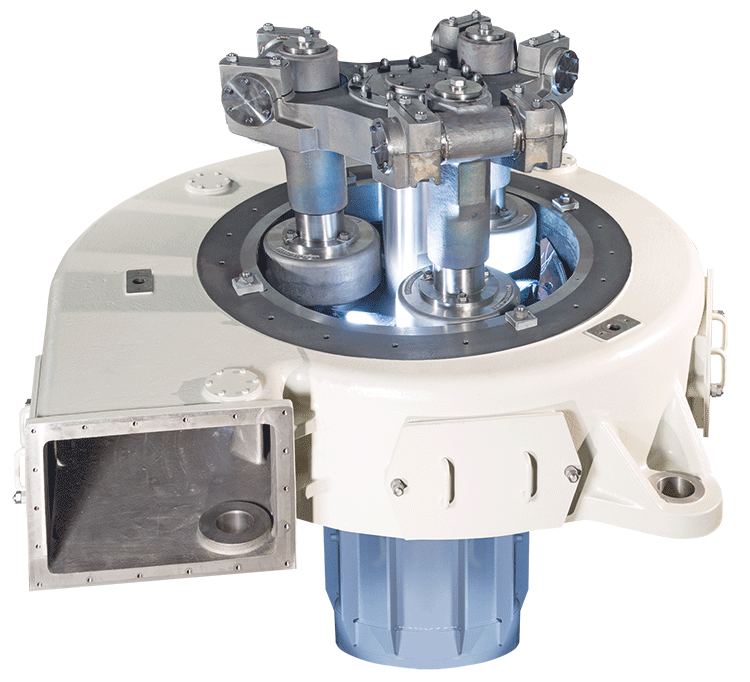

Vertical agitated dry media mill

A vertical agitated media mill is used for grinding ultrafine particles, in an agitated (or...

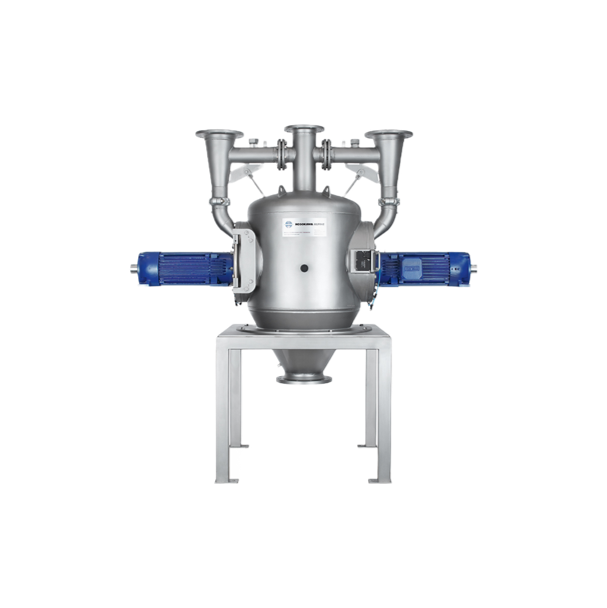

Horizontal chemical scraper centrifuge

For slurries difficult to discharge, a scraper can improve process reliability, effi...