Carbon Black Production Technology

Find innovative production technology for making carbon black and connect directly with world-leading specialists

Carbon blacks are fine pigment particles that consist mainly of carbon. Its production became popular in the second century with the establishment of paper production. Hydrocarbons such as oil and natural gas are the basic raw materials for manufacturing them. However, the properties of carbon black differ depending on the processes carried out with the use of carbon machinery and production technology.

Technology picks for carbon black

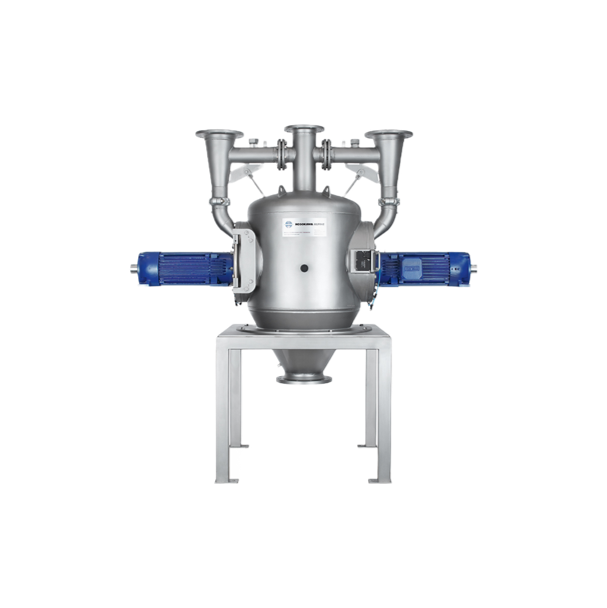

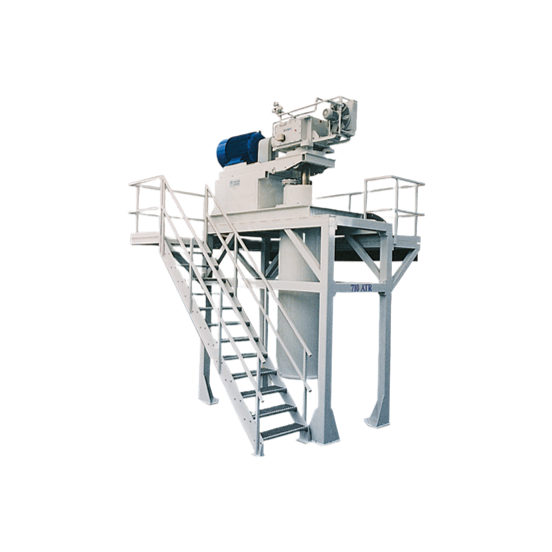

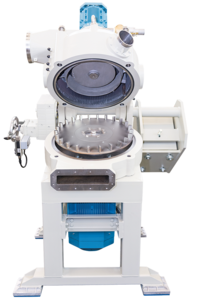

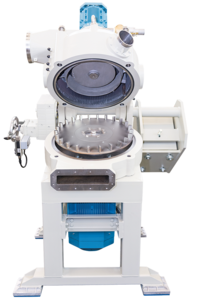

Classifier mill for recovered carbon black

Recovered Carbon Black (rCB) can be recycled back to the tire production chain ...

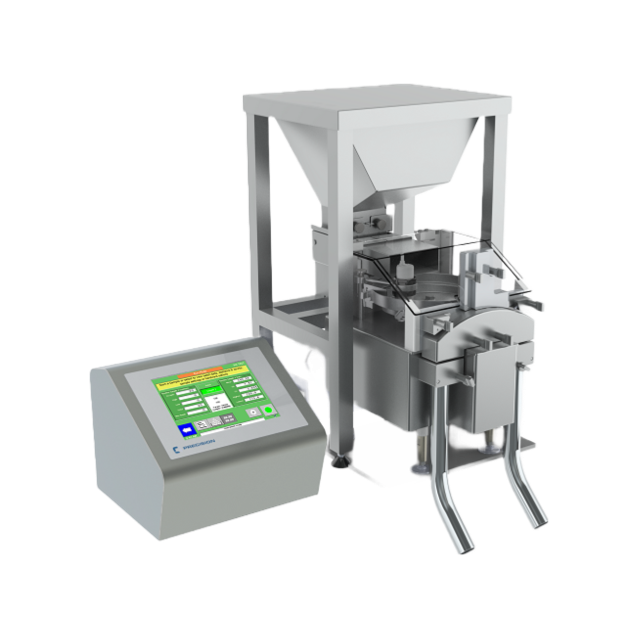

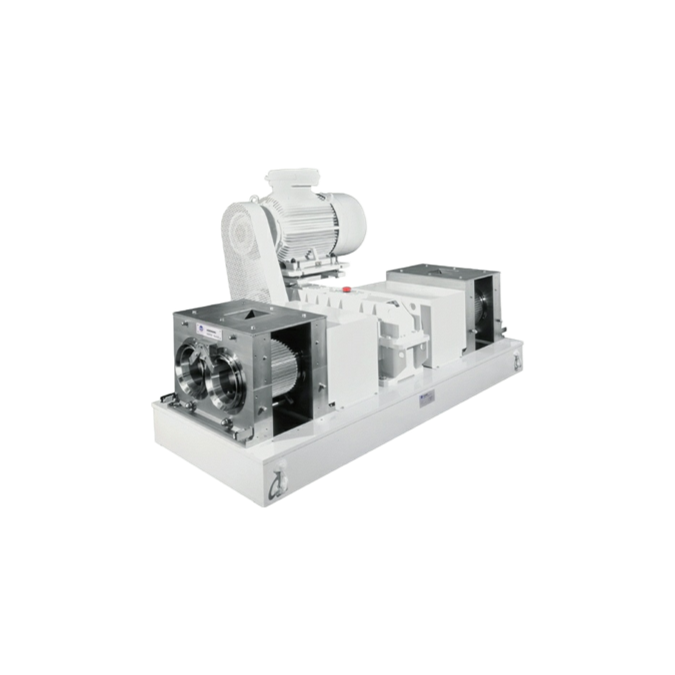

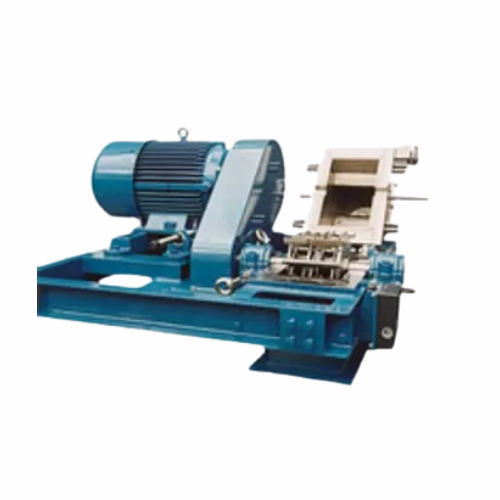

High-speed pulverizer for carbon black production

Industries processing materials like carbon black or paracetamol requir...

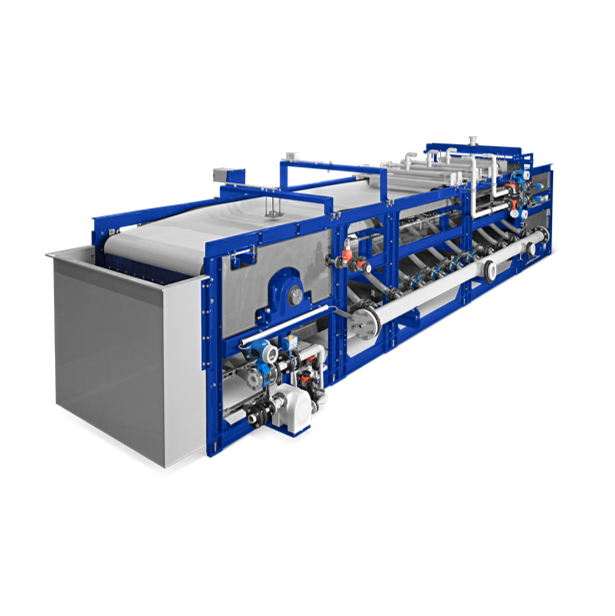

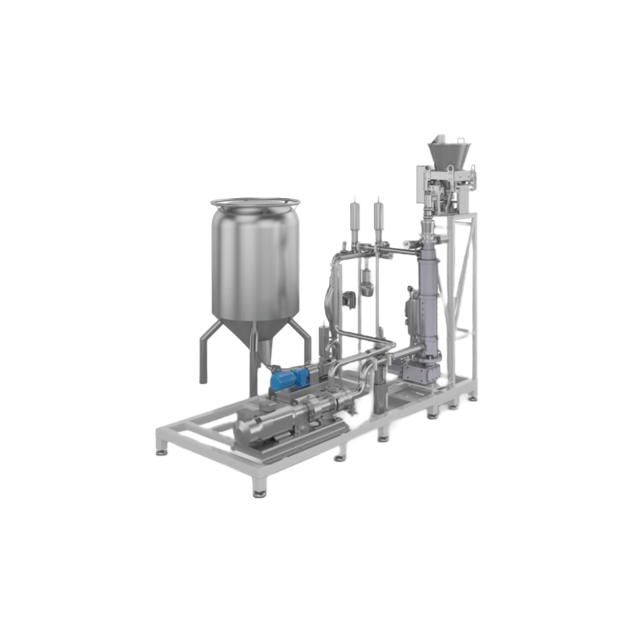

Industrial conveying system for carbon black and silica

In rubber compounding, the safe and efficient transportation of r...

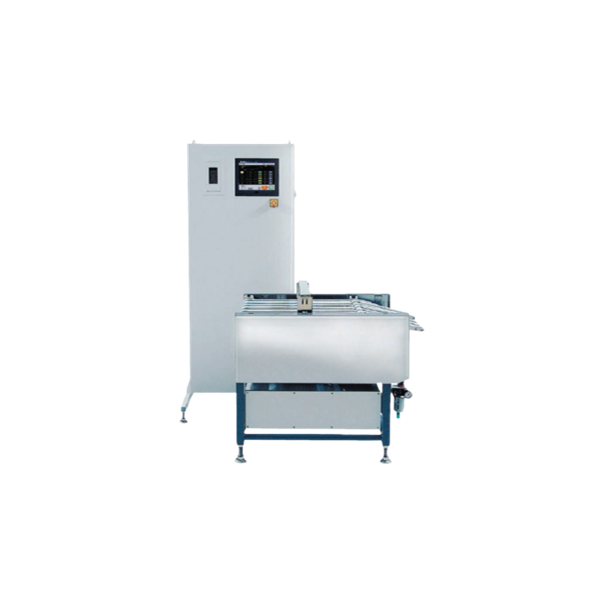

Oil absorption testing instrument for carbon black and silica

In the chemical industry, ensuring compliance with interna...

Tell us about your production challenge

Manufacturing carbon black in a carbon black making machine

Producers of traditional carbon black use one of two manufacturing processes. These are either the oil furnace process or thermal process. For the oil furnace process, they heat and continuously inject aromatic liquid oil into the gas-fired furnace. They cool the carbon particles by passing them through heat exchangers and direct water sprays and filter them using a fabric filter. Finally, they use a carbon black pellet machine to convert the recovered carbon into marketable pellets for tire, rubber, and plastic products. Carbon pelletization is important because it increases its density and thermal stability, making it safe for storage and packaging.

The thermal process is cyclical and involves the use of two furnaces to decompose natural gas. When the first furnace black produces carbon and hydrogen, you cool it. Then, use the second one while you heat the first one.

Environmental impact of carbon black

The production of carbon black through the combustion of fossil fuels generates emissions associated with many negative effects both on humans and the environment. It has been linked to congenital disabilities, cancer, respiratory and cardiovascular diseases. Its ability to affect rain and cloud patterns makes it a key contributor to climate change. For this reason, silica is overtaking in terms of popularity due to the fact that it is a natural materials found in the earths crust. A solution to reducing carbon blacks impact on the environment is to produce it by using abandoned tires as the feedstock in the carbon black machine.

This is a safer, environment-friendly substitute because the manufacturing process removes carbon dioxide from the environment and reduces air pollution.

Green alternative to carbon black

The hazardous impact of carbon black on both human and environmental health has led to a rise in the demand for green alternatives like recovered carbon black. Its manufacturing process, which is the pyrolysis of waste tires during recycling, is eco-friendly. It differs from traditional carbon black production methods, which involve burning petroleum products.

Using and recycling abandoned tires is economical and safer for the environment because it is cheap and reduces the emission of carbon dioxide. In addition, recovered carbon black possesses a great ability to strengthen mechanical rubber products due to its low ash content. This characteristic makes it a better and less polluting substitute.

Processing steps involved in carbon black making

Which carbon black technology do you need?

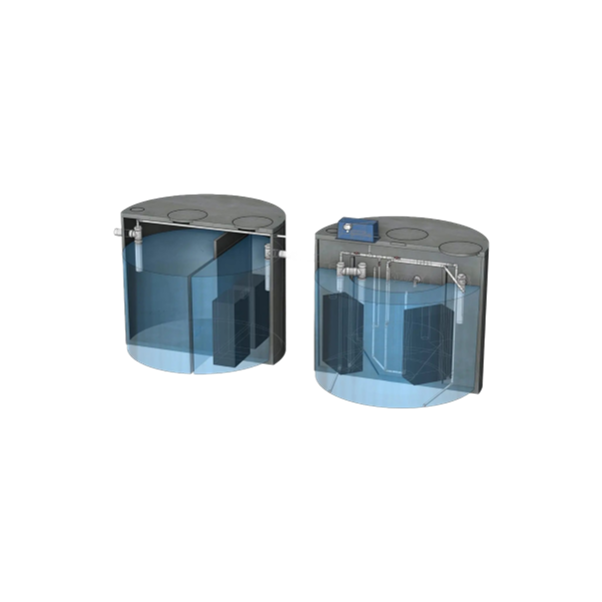

Co2 recovery and liquefaction system for biogas upgrading

In biogas upgrading and carbon capture operations, maintaining...

High-speed pulverizer for carbon black production

Industries processing materials like carbon black or paracetamol requir...

Powder synthesis reactors for nanometer and micrometer particles

Industrial production of high-quality powder materials ...

Oil absorption testing instrument for carbon black and silica

In the chemical industry, ensuring compliance with interna...

Dry granulation technology

In pharmaceutical, chemical, and food industries, the need for improved powder processing methods...

Industrial conveying system for carbon black and silica

In rubber compounding, the safe and efficient transportation of r...

High-temperature screw conveyors for bulk solids

In environments such as foundries, coal power stations, and drying plants...

Agitator bead mill for flow chemistry

During the early stages of synthesis, generating only limited product quantities can ...

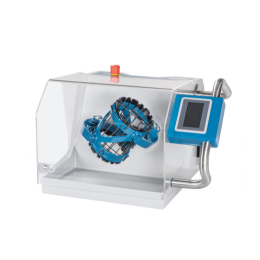

R&D shaker mixer for battery powders and chemicals

Material heterogeneity, agglomeration, and contamination are key param...

Classifier mill for recovered carbon black

Recovered Carbon Black (rCB) can be recycled back to the tire production chain ...

Automatic bag slitter

Unacceptably high dust levels can be generated whilst manual emptying and handling of bags, also produc...

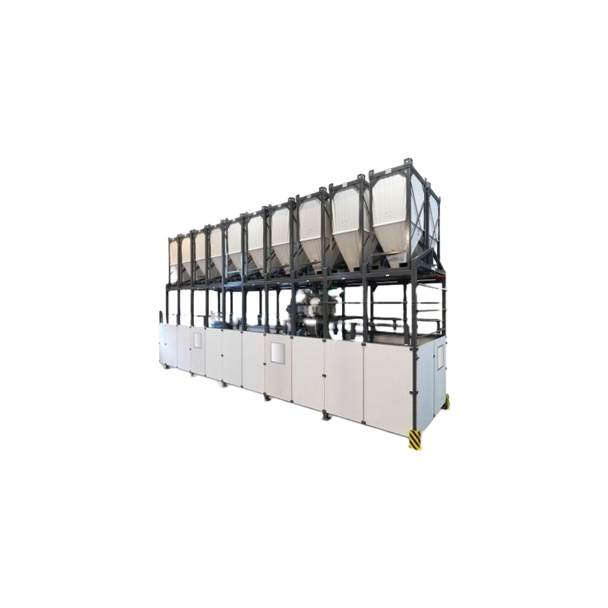

Hygienic FIBC handling line

There are many considerations when handling FIBC’s (Flexible Intermediate Bulk Containers)...

2-way diverter valves for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diverted...

Multi-way diverter valve for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diver...

Dense phase conveyor for normal wearing materials

Dense phase pneumatic conveying is used for powders, granules, and grai...

Dense phase conveyor for powders and granules

Some manufacturing and filling operations require a smaller pneumatic transp...

Wear resistant bends for pneumatic conveying

Bends in pneumatic conveyor lines cause load loss leading to lower flow rates...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...