Making Chili Sauce

Find innovative production technology for making chili sauce and connect directly with world-leading specialists

Chili sauce is produced worldwide, but each is augmented by the cultural elements of where it is made. Most chili sauces consist primarily of chilis, though some preparations include tomato as the primary ingredient. Vinegar, sugar, and salt are added to the chili sauce making machinery, and the mixture is thickened mainly by cooking.

Technology picks for chili sauce production

Production solutions for convenience foods

In today’s fast-paced world, the demand for healthy, prepared meals is on...

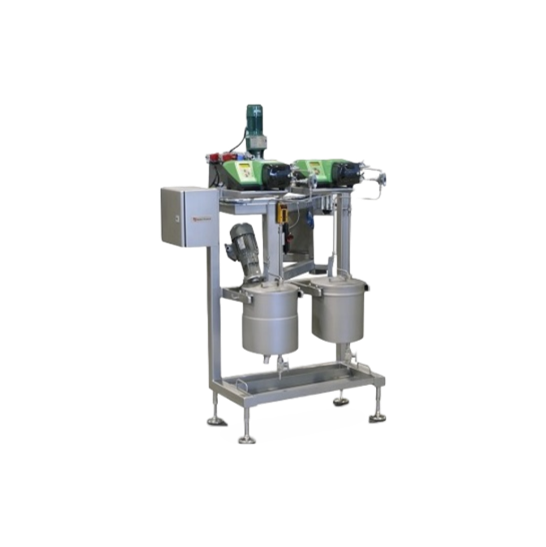

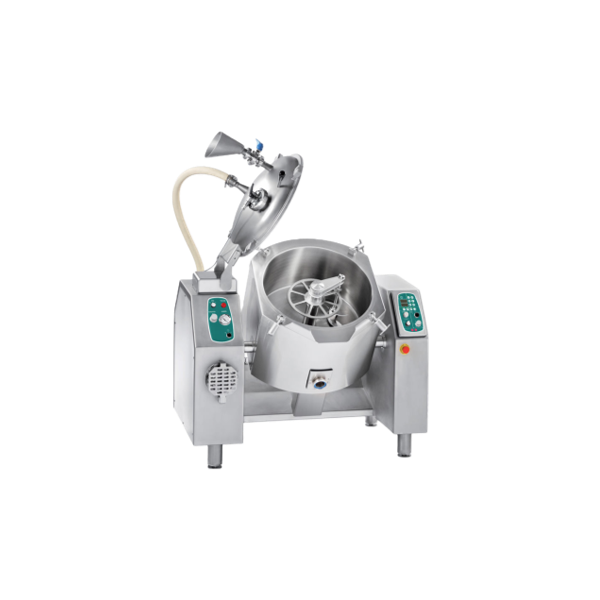

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

Compact industrial sauce pan

Safe, reliable cookers that operate unobtrusively are required in any kitchen where space and t...

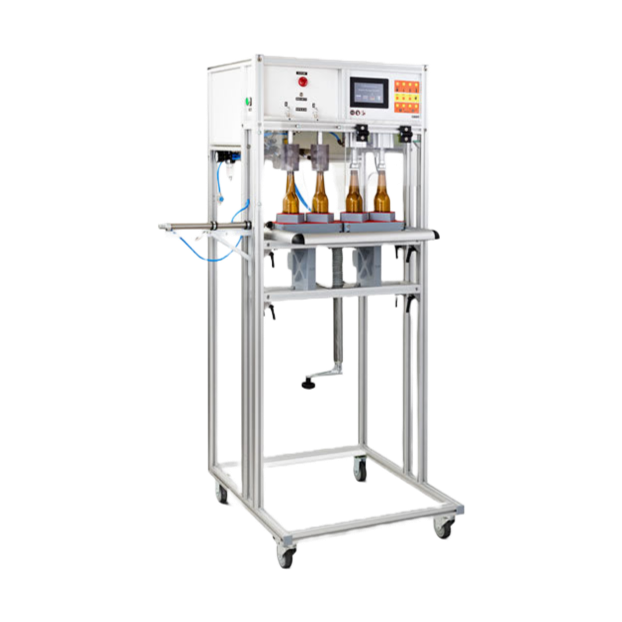

High-precision rotary weight filler for edible oils and sauces

Achieving consistent filling precision and minimizing pro...

Stories about chili sauce

Tell us about your production challenge

The hidden hotness of chilis unveiled

The magical heat of the chili pepper comes from their natural defense mechanism against would-be mammalian predators. Capsaicin is the active component of chili peppers that imparts a powerful burning sensation after ingesting. Biting into a chili pepper releases the chemical, which then binds to pain and temperature receptors. The highest concentration of capsaicin is found in the membrane directly surrounding the seeds of chili peppers, but the seeds themselves contain none.

The concentration of capsaicin in the chili decreases with distance from the seeds. Based on capsaicin concentration, the Scoville scale is used to estimate relative pungency. The unique burn of chili peppers has made them a staple ingredient in many cultures, adding a new dimension to the taste of any dish.

Chili sauce processing machines: Firing up your process for making chili sauces

Chili processing begins with the cleansing of prospective peppers, followed by blanching in a boiling tank or steam chamber. You then grind down the chilis with a chili sauce grinder machine, adding water as necessary to ease grinding. A colloid mill is often used for this process. During this stage, you typically remove the pepper peels, and if looking to tame the spicy flavor you may remove the seeds as well. It should be noted that Often, the seeds are processed into various powders which can be used for a variety of different applicationse.

The ground chili paste is now ready to be combined with your other ingredients in a stainless steel mixer and should be boiled to incorporate all the elements and thicken the sauce. While cooling, acetic acid, sodium benzoate, and sorbic acid should be added below 80ºC, and ascorbic acid must wait until the mixture cools to 65ºC. Bottling should also occur at 65ºC to prevent the growth of microbes. It’s also worth noting that prior to packing and labeling, bottles should be stored in a cool dark place for a week or two to screen for defects.

Serving your spicy sauce, better thick than quick

In its raw form, chilli sauce is usually quite thin due to its high water content. Thicker sauces are often more practical for consumption, so chili sauce processing equipment such as a mixer and cooker provides the opportunity to achieve a more desirable consistency. Starches such as cassava starch are commonly added to chili sauces to bulk up the viscosity. In addition, cooking the sauce allows you to boil off excess water, further condensing the mixture. Thicker liquids are sometimes more difficult to process, so to incorporate all ingredients you require high shear mixers or agitators. In addition, after cooking, the sauce is rapidly cooled using a fan to help the mixture further thicken.

The not-so-sweet truth about sugar content

Perhaps somewhat surprisingly, chili sauces often contain fairly large amounts of sugar. In sweet chili sauce, sugar makes up 30% of the composition or more. Sugar-free chili sauces provide fewer calories while sacrificing relatively little in the way of flavor. To achieve this, sugar substitutes such as stevia, erythritol, or other sugar alcohols are commonly used to add sweetness without the extra carbs. The process of developing these sugar-free alternatives remains largely the same, though you should consider how your chosen sweetener might interact with your formula differently than table sugar. Most notably, aspartame can lose its sweetness with heating.

Processing steps involved in chili sauce making

Which chili sauce technology do you need?

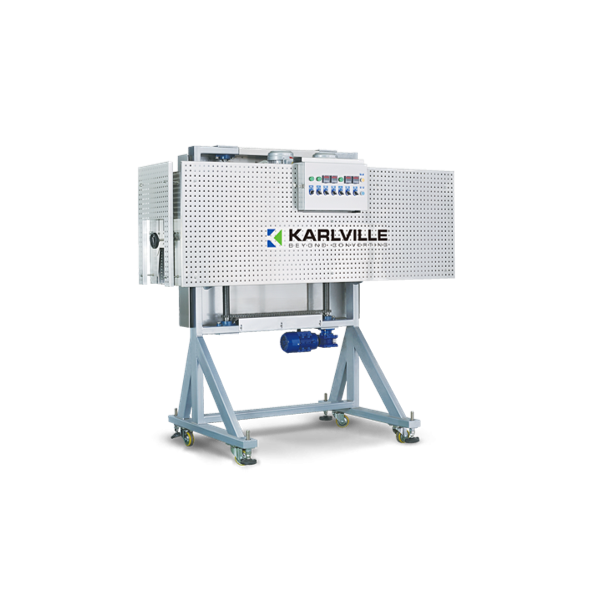

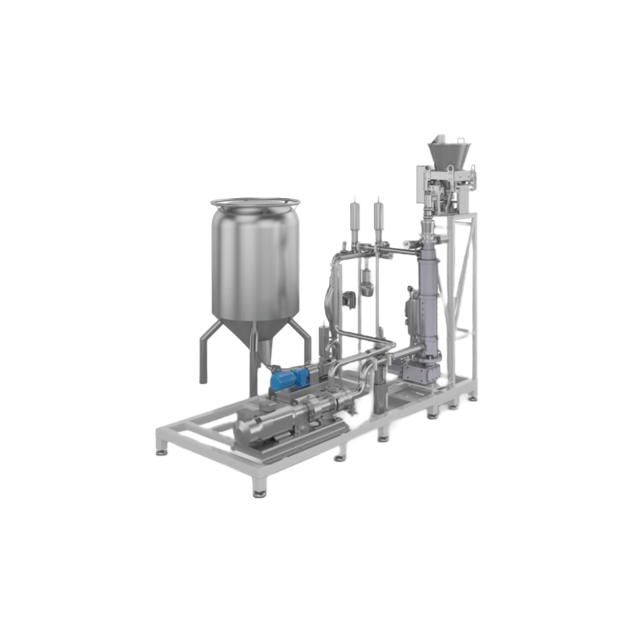

Continuous mustard line

In high-volume food production, maintaining product consistency and quality is vital. Challenges aris...

Vacuum and pressure cooker for fruits and vegetables

When producing fruit-based products such as marmalades or ice cream ...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Shrink wrapping machine for PET bottles

During a shrink-wrapping process, a change of reel can slow down the production cyc...

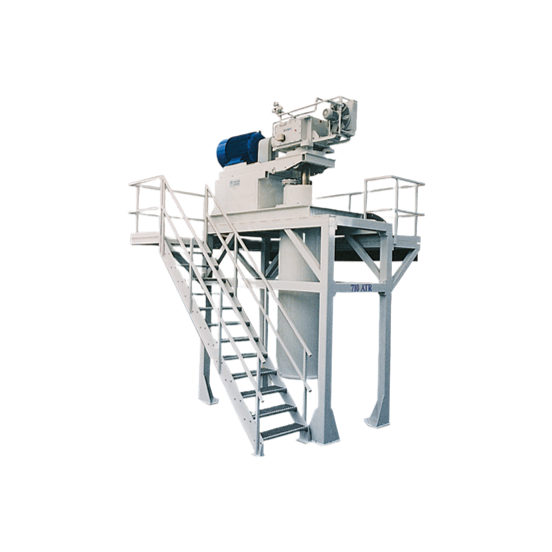

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Automatic filling machine for sauce

Traditional sauce filling units can struggle to maintain a high quality of output in ca...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

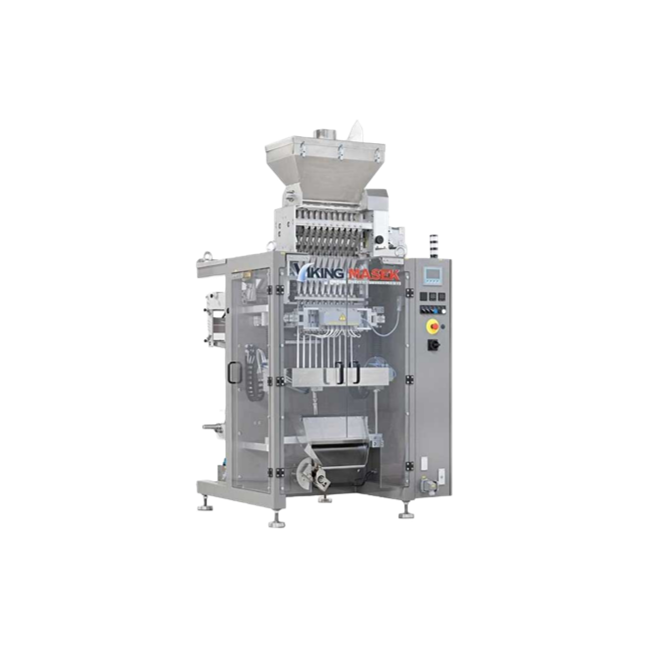

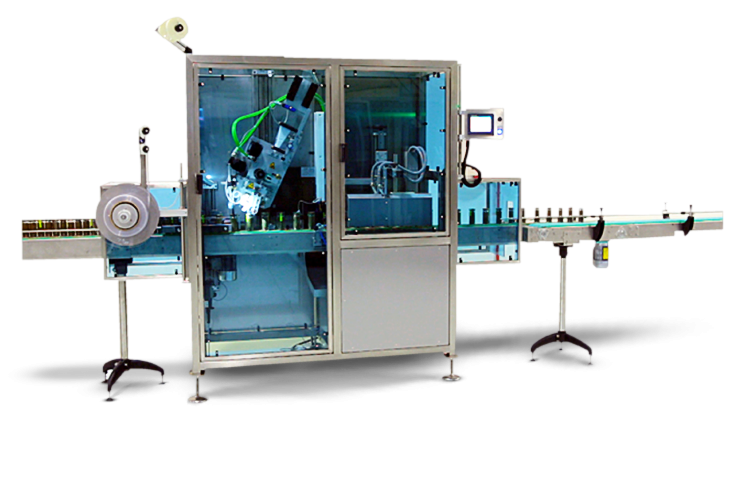

Shrink sleeve applicator - 400 per minute

Flexible medium to high speed application of shrink sleeveing to containers is u...

Compact shrink sleeve applicator

Adding tamper prevention to product packaging can be expensive and difficult to set up. Thi...

Electric shrink tunnel solution

Adapting shrink sleeve heating tunnels for different applications can be a lengthy and expen...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Industrial vegetable cutter

Retaining freshness in cut vegetables, as well as retaining vitamins and nutrients, is a top pri...

Full crate inspection system

State of the art crate inspection system that uses a laser camera system to see if the bottles ...

Empty crate inspection system

Extensive and much-differentiated inspection of both the crate and the bottle that allows you ...

Versatile stone mill machine

In the food industry, when it comes to milling a wide range of products such as seeds and nuts ...