Making Chocolate Spread

Find innovative production technology for making chocolate spread and connect directly with world-leading specialists

Consumers usually eat chocolate spreads along with bread, or other grain-based items, such as pancakes, biscuits, waffles, and others. Although one particular brand has dominated this market for more than 50 years, there is still a place for new, health-friendly innovations and production ideas using chocolate spread machines.

Technology picks for producing chocolate spread

Automatic chocolate processing line

In modern confectionery production, achieving consistent quality of chocolate, creams, ...

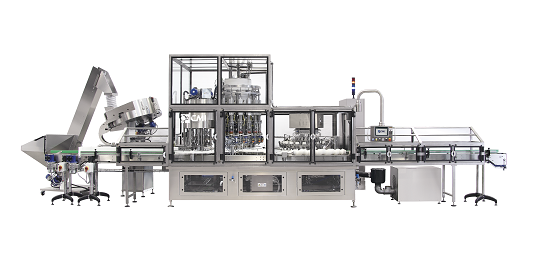

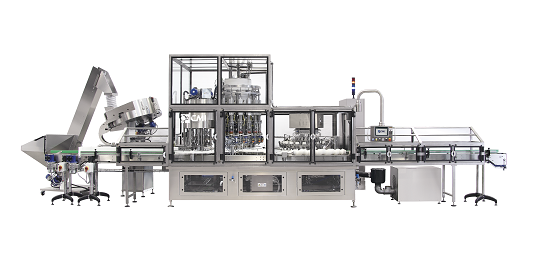

Filling machine for viscous products

Chocolate paste and other viscous liquids require special handling to obtain the optim...

Industrial spreading systems for sticky products

Handling sticky products that require subsequent chocolate coating can be...

Chocolate and spreadable cream dispenser

In patisseries, cafes, and ice cream shops, there is often a need to efficiently a...

Tell us about your production challenge

Major production steps and utilization of chocolate spread machines

To produce a high-quality chocolate spread, start with the base chocolate. It is where you incorporate a pasty mass of cocoa and sugar. Specifically, the sugar grounds need to be 100 microns in terms of particle size. As you add more ingredients to the chocolate spread machine, cylinders refine the particle size further to 10-20 microns. Then, it is time to mix it with cocoa butter. Conching is also a critical process for a great chocolate consistency. It does this by gradually applying frictional heat, promoting fluidification or dispersion of sugar and cocoa particles in its fatty phase. In turn, it also releases organic compounds and volatile gasses in a process called degassing. This enables the consistency of a fluid pasty mass that can be easily molded.

Sugar substitutes and other sweetener alternatives

Sugar is a sweetening agent, as well as the responsible for the consistency and texture of the chocolate spread. In most commercial spreads, sugar has a big impact due to market, cultural, or expense purposes. As an additive, you can replace it with alternatives such as xylitol, erythritol, D-psicose/psicose, and other low-calorie sweeteners. These sweeteners are organic and a healthier choice than refined sugar. Since sweetness is subjective, the base chocolate is still a key part of the spread – whether or not you use a natural sweetener – as it will balance out all the flavors.

Demand for vegan-friendly chocolate spreads

Vegan chocolate spreads are also possible with the right ingredients and additives. Due to intolerances to lactose and other milk components, or for environmental reasons, consumers nowadays are finding alternatives to milk-based chocolates. Milk replacers such as rice milk, soy milk, and lupine milk all have the potential in replacing animal milk. In terms of fat, hazelnut, almond, and coconut fat are all feasible choices to replace milk fat. The chocolate paste-making process is still similar to the original process, with the aid of chocolate paste machines or a chocolate spread making machine.

Food standards for chocolate spreads

The FDA imposes regulations on chocolate spreads based on milk chocolate; it must contain not less than 12% by weight of nonfat milk, exclusive of any sweetener or other dairy-derived ingredient. It must also have safe and suitable vegetable-derived oils and fats, other than cacao fat. On the other hand, the EU legislation on cocoa and chocolate products allows for the use of six tropical vegetable fats, to a maximum of 5% of the chocolate component of the finished product. Both governing bodies pay close attention to appropriate labeling of fat content – you must mention fats other than cocoa butter.

Processing steps involved in chocolate spread making

Which chocolate spread technology do you need?

Chocolate melting trays for small-scale applications

In the field of chocolate production, small-scale or event-based mel...

Melting and mixing kettles for chocolate production

In large-scale chocolate production, maintaining precise temperatures...

Melting and mixing kettle for chocolate production

In the chocolate production industry, efficient melting and mixing of ...

Precision chocolate production from cocoa nibs

In the chocolate manufacturing industry, obtaining the right particle size ...

Double heating cabinet for melting and preheating chocolate

In confectionery production, maintaining optimal temperature...

Electric melting tray for small-scale chocolate applications

When working in small confectionery setups or temporary eve...

Compact chocolate moulding solution 3-in-1

When producing different colored chocolate moulds or decorating fresh fruit cup...

Chocolate moulding line for center-filled chocolates

Creating diverse, high-quality center-filled chocolates in a product...

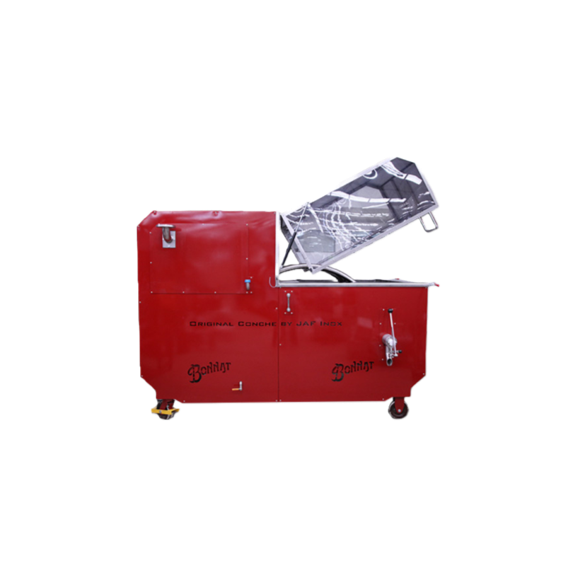

Conching solution for chocolate processing

In the context of large-scale chocolate manufacturing, achieving a consistently...

Chocolate cooling tunnel

In the chocolate production process, rapid and uniform cooling is crucial to ensure proper crystalli...

Medium capacity filling line for food and cosmetics

In industries that handle food, cosmetics, or household products, eff...

2-head liquid and viscous product filling system

In many production facilities, accurate and efficient filling of liquids,...

Wafer sheet cream application system

In the wafer production process, applying cream between wafer sheets can be a challeng...

Stainless steel chocolate tank for storage and processing

In the chocolate production industry, maintaining the quality ...

Gear or piston filling-dosing equipment for creamy and thick foods

In food processing, precise dosing and filling of pr...

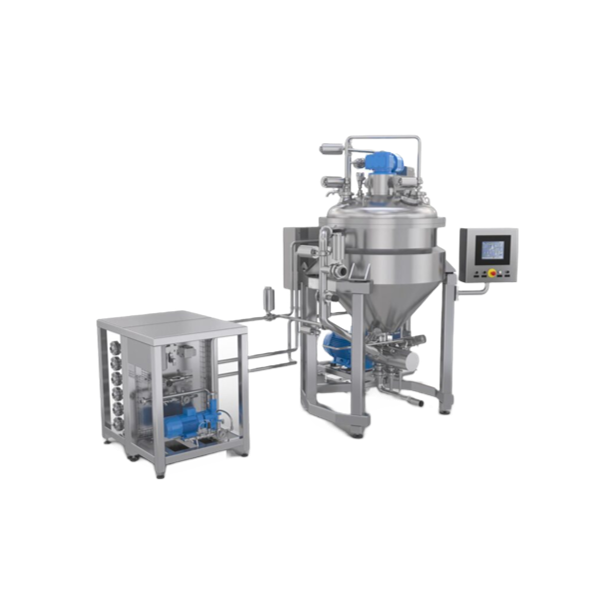

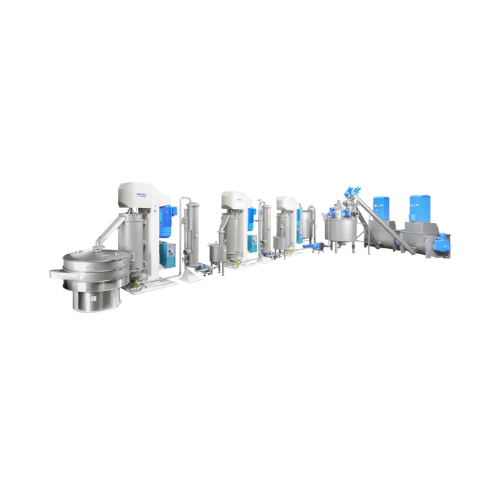

Fully automatic chocolate processing line

Producing high-quality chocolate, creams, and fat-based compounds requires preci...

Laboratory batch chocolate processing unit

In the research and development of new chocolate and compound recipes, precisio...

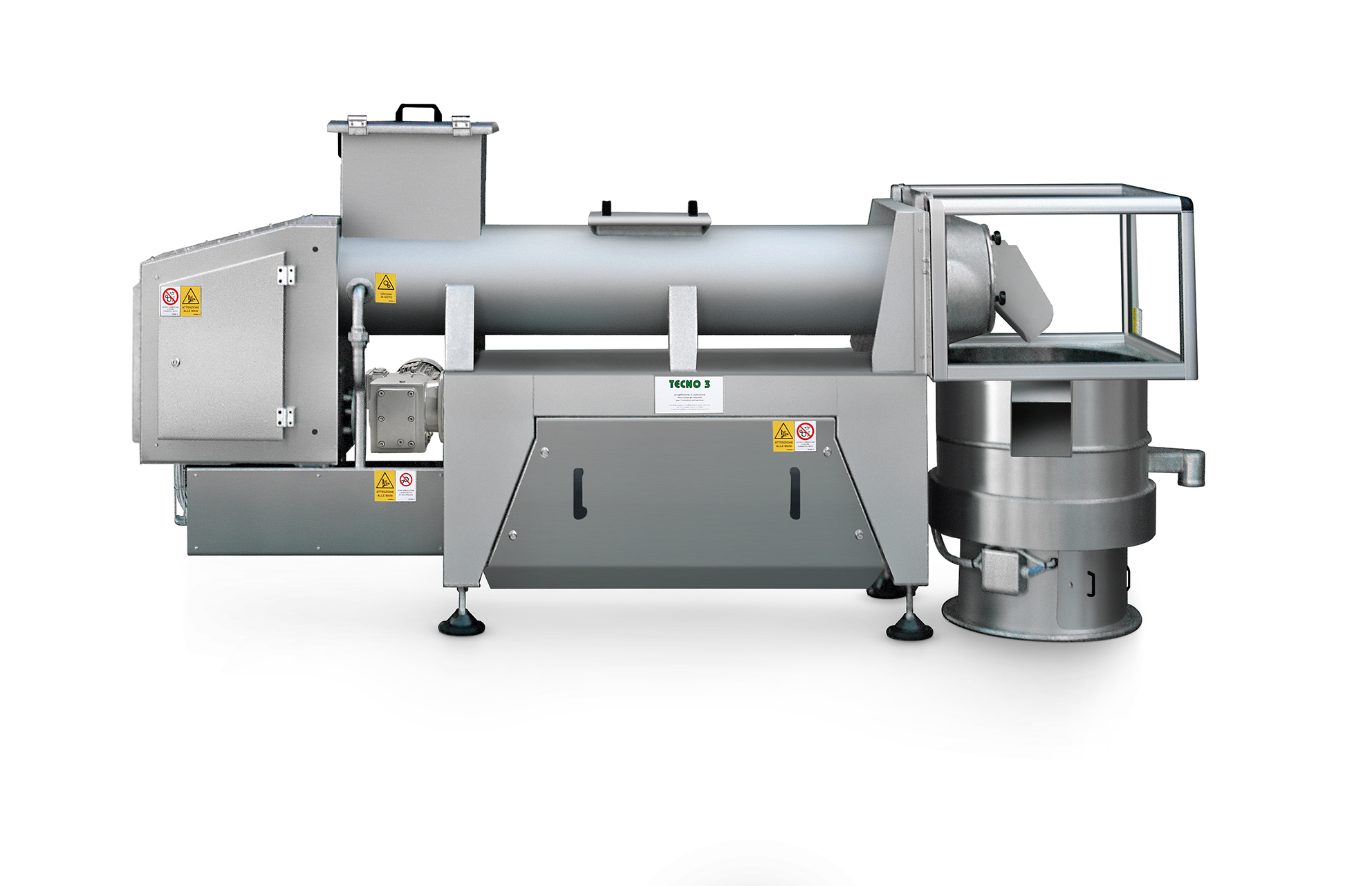

Chocolate processing unit for mixing and grinding

Producing high-quality chocolate, creams, bread spreads, and fat-based ...

Automatic chocolate processing line

In modern confectionery production, achieving consistent quality of chocolate, creams, ...

Ball mill refiner for cocoa liquor and chocolate production

When producing fine cocoa liquor or chocolate, achieving uni...

Chocolate processing production line

In large-scale confectionery manufacturing, achieving consistent product quality while...

Scraped surface sterilizer for high viscosity liquid products

In the production of aseptic preparations, ensuring the st...

Chocolate spraying system for bakery decoration

In the confectionery and bakery production, precise chocolate application ...

Chocolate enrober for large scale production

In large-scale chocolate production, maintaining precise temperature control ...

Auxiliary feeder mixer for chocolate production

In modern chocolate production, the need to seamlessly blend various inclu...

Rotating stencil depositor for confectionery products

In the production of confectionery items like meringue masses, spon...

Accurate chocolate tempering measurement tool

In the chocolate production industry, ensuring the temper quality of chocola...

Rotary piston fillers for pumpable products

In the food industry, filling containers with pumpable products requires preci...

Bulk chocolate storage for confectionery production

In chocolate production, maintaining consistent temperature and flow ...

Vertical tunnel for cooling and moulding chocolate

When producing molded chocolates, maintaining optimal cooling consiste...

Professional chocolate tempering system for chocolatiers

Ensuring chocolate is perfectly tempered can be challenging, esp...

Chocolate and spreadable cream dispenser

In patisseries, cafes, and ice cream shops, there is often a need to efficiently a...

Refiner for spreadable cream and chocolate

In small to medium-sized confectionery workshops, achieving a smooth, homogenou...

Chocolate tempering solution for small scale production

In artisanal chocolate production, maintaining precise temperatur...

Professional chocolate tempering equipment for efficient production

In medium to large chocolateries and patisseries, m...

Chocolate enrobing and cooling tunnel 300/400 mm

In the production of high-quality enrobed and moulded chocolate products,...

Energy-saving cooling system for vegan products

High-viscosity products like hummus or chunky pasta sauces must be cooled ...

Mixer for production of chocolate with inclusions

Using the same mixing equipment for different recipes in chocolate manu...

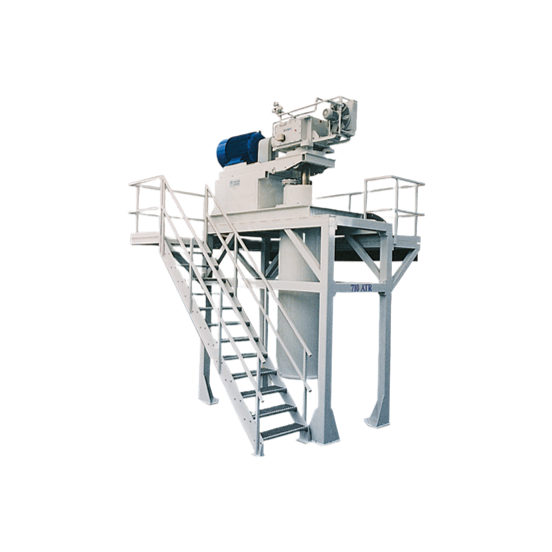

Refining plant for chocolate

Achieving a balanced, velvety mouthfeel in chocolate is challenging. Larger particles in chocol...

Industrial melter for chocolate rework

Wastage or out-of-specification products are not uncommon in the chocolate manufactu...

High-speed chocolate block melt machine

If you produce chocolate using larger blocks instead of cocoa beans, chocolate melt...

Entry level cocoa roaster

The biggest challenge that small-scale cocoa processing manufacturers face is even and thorough ro...

Industrial washer for plastic crates

In the food production sector, hygiene regulations are getting stringent by the day. E...

Industrial fine milling equipment for nuts

In a bakery environment fruit jams are often used for the decoration or filling...

Small capacity cocoa grinder

The first step of producing almost any kind of chocolate starts with grinding cocoa beans to ge...

Entry level bean to bar line

One of the challenges when setting up a small-scale cocoa processing factory is making all of t...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

Industrial bottle washing machine

Polyethylene terephthalate (PET) and glass bottles are widely used in the beverage indust...

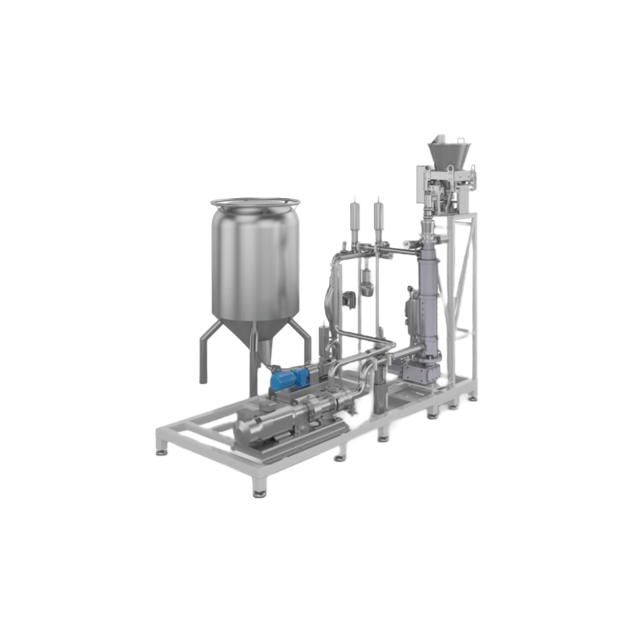

Filling machine for viscous products

Chocolate paste and other viscous liquids require special handling to obtain the optim...

Small scale cocoa beans processing machine

For the highest quality chocolate production, complete control of the entire pr...

Entry level bean-to-bar machine

The production of high-quality chocolate from the bean can often be out of the reach of smal...

Small capacity chocolate melangeur

In order to produce the finest of chocolate products, you need the cocoa nibs to be grin...

Chocolate refiner with chiller

Milled beans need further reduction in particle size before they can be sent to a conche for ...

Longitudinal chocolate conche

High-quality chocolate requires specialized conching. Precise control of temperature and mixin...

Multi-functional food processor for a high sugar percentage pastes production

For the development and production of hi...

Flexible mixing system for whipped cream and pastries

Delicacies such as meringue, ganache, and marzipan undergo various ...