Croissant Making Equipment

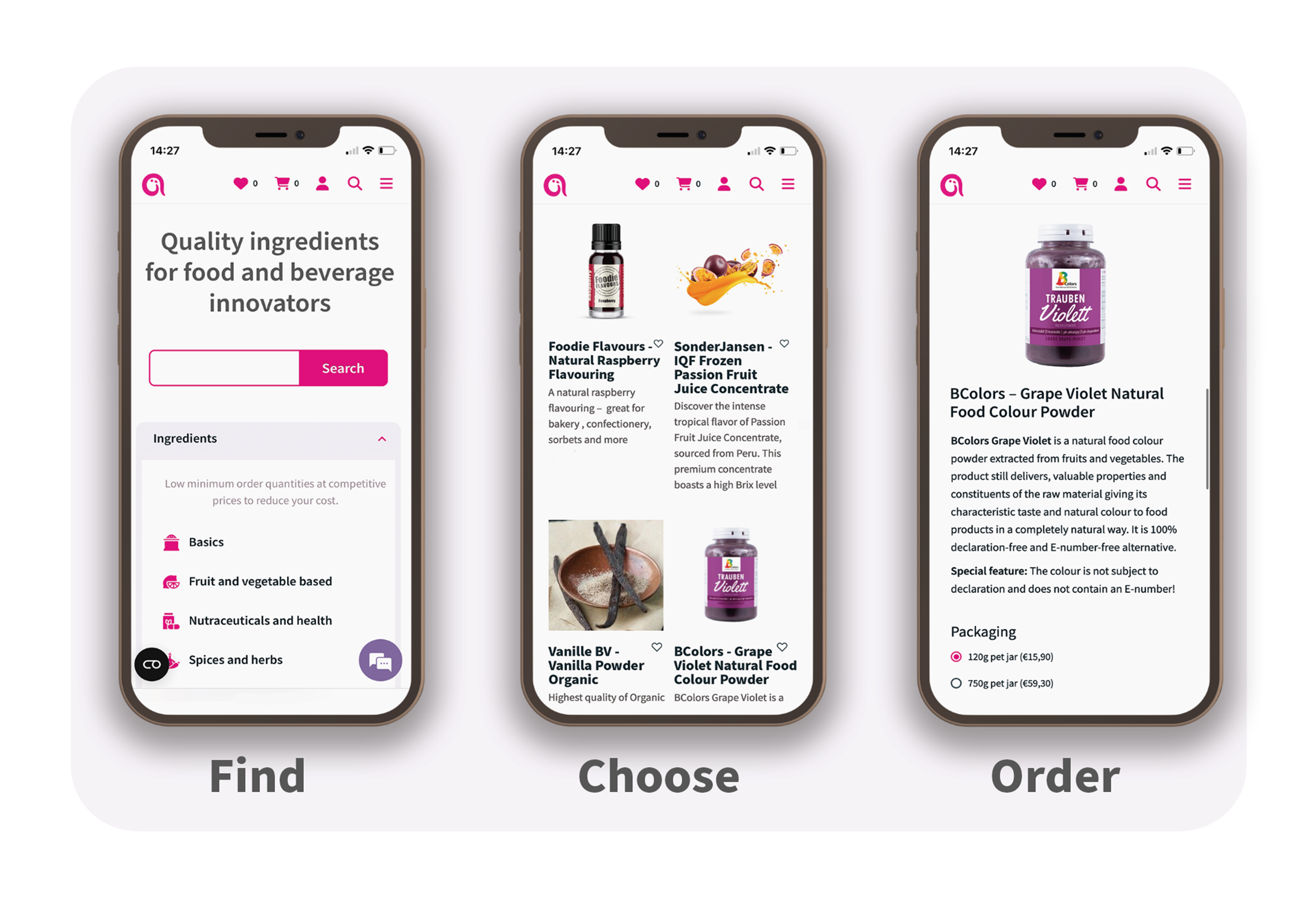

Find innovative production technology for making croissants and connect directly with world-leading specialists

Croissants have crossed global barriers to become a widely consumed pastry, unique for its rich buttery taste and crispy exterior. Regardless of location, the croissant production process involves creating laminated dough by repeatedly folding and rolling butter into dough. Temperature regulation is crucial to the croissant making process as too warm temperatures negatively affect the overall outcome.

Stories about croissants

Tell us about your production challenge

Why is lamination important in the croissant making process?

An ideal croissant has a flaky exterior and a delicate honeycomb appearance on the inside. These are direct outcomes of the process of laminating. During lamination, producers fold and roll butter into the dough to create multiple super-thin layers of dough. The fold pattern could be an envelope fold, single, letter, or book-fold. They can achieve this on a large scale production line with the help of bakery equipment such as a professional dough sheeter. Dough laminating ensures that open pockets form in the interior as the croissant bakes while the exterior develops uniform flaky stripes.

Varieties of croissants made from a croissant making equipment

Croissants come in two major forms; the straight croissants and the c-shaped or crescent-shaped ones. Although these shapes appear to reflect a baker’s choice and creativity, they actually represent the key ingredients in the croissant.

Generally, straight croissants contain 100% butter, while curved ones contain other fats such as oil or margarine. To create these varieties, bakers alter the cutting and rolling pattern of the dough. They could cut them into triangles or rectangles and might either roll or leave the edges straight. It’s important to ensure the dough is protected from heat during this process because too much heat will melt the butter and ultimately affect the texture of the croissant.

Croissants for vegans

Even though croissant making equipment will generally include ingredients like butter, milk, and eggs to create the ideal croissant, vegans can still enjoy this product by using plant-based alternatives to butter, eggs, and milk. Vegan butter, which is a combination of water and a plant-derived oil like olive or avocado, can help to achieve a buttery and chewy croissant. Olive oil and coconut oil are good substitutes for egg wash because they provide uniform browning. Dairy-free milk from almonds and oats does the job of providing a gorgeous sheen to the croissants.

The role of proofing when making croissant

Proofing is a crucial step in baking food items like croissants, which require incorporating air pockets into the mixture. During this stage, which is usually after cutting the doughs into shapes, the yeast cells release carbon dioxide gas after consuming sugar. This step is vital to achieving the optimal texture of the croissant. If it is over-proofed, the laminated layers will separate and cause the butter to leak out. On the other hand, under proofing creates a very dense croissant. Generally, achieving ideal proofing in frozen croissants is challenging because ice crystals form in the dough and affect yeast viability. However, a freezing rate of ≥ −3.19 °C min−1 is suitable to achieve the desired texture.

Processing steps involved in croissants making

Which croissants technology do you need?

Croissant production module for pastry make-up lines

Producing a diverse range of croissants efficiently can be challengi...

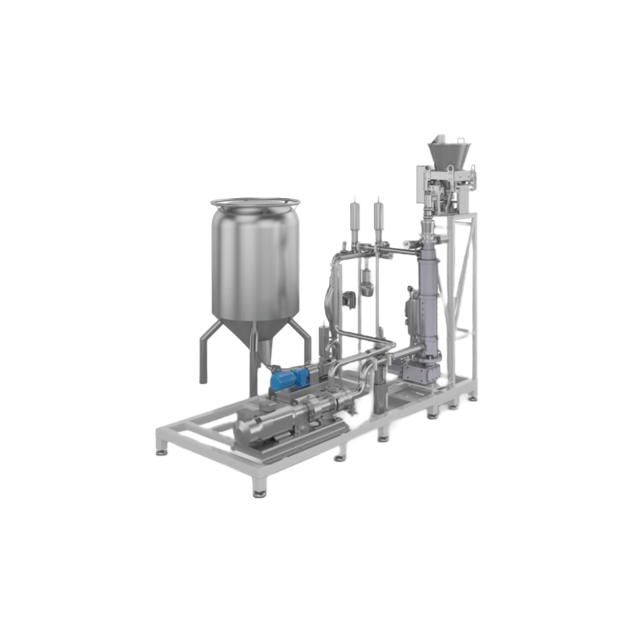

Industrial dough laminator for croissants and pastries

Producing high-quality croissants and pastries requires precise la...

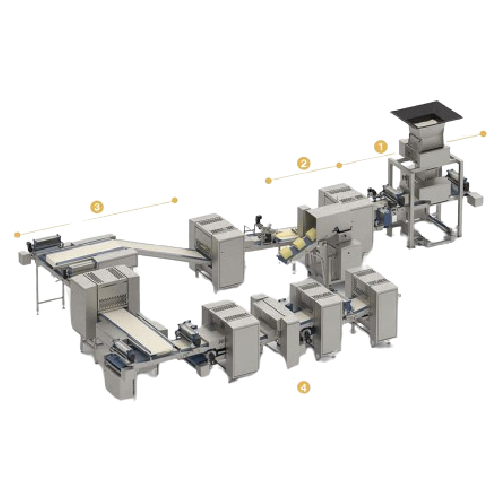

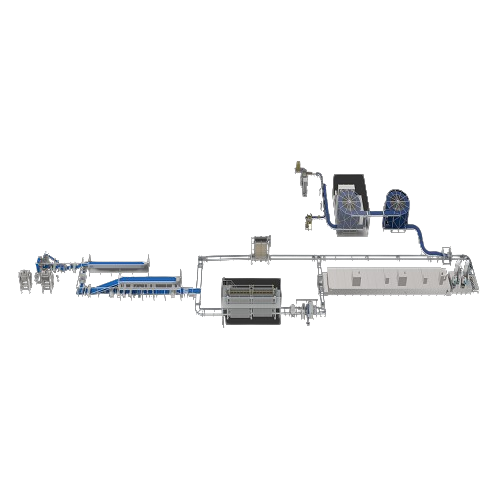

Pastry production line for large-scale bakeries

When scaling up pastry production, ensuring consistency and efficiency is ...

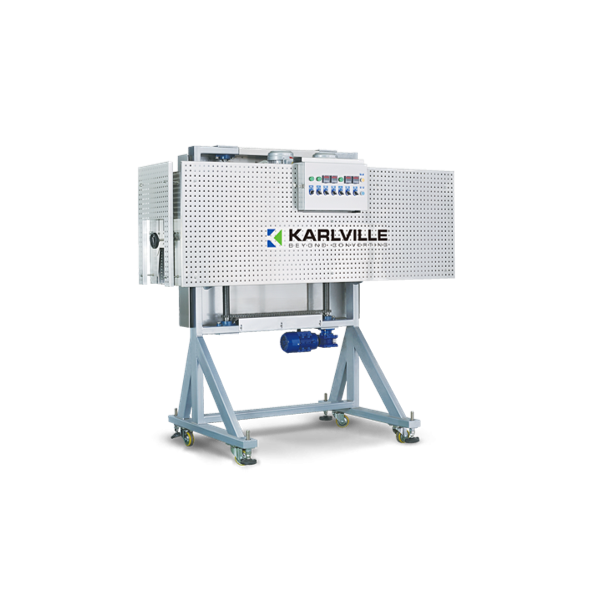

Dough laminating equipment for croissants and pastries

In a semi-industrial to industrial bakery, producing high-quality ...

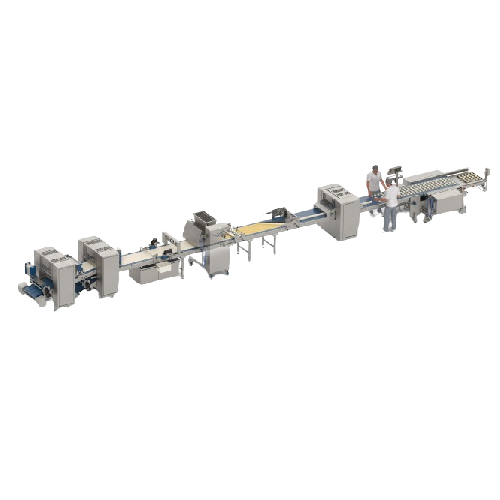

Industrial croissant production line

In large-scale bakeries, achieving consistent and high-quality croissants can be chall...

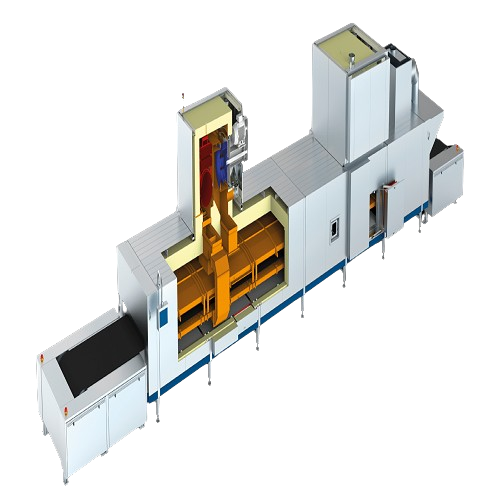

Automatic oven loading and unloading system

In high-volume baking operations, ensuring consistent and efficient product fl...

Medium duty mixer for breads and pastries

In commercial bakeries, achieving consistent dough development is essential for ...

Industrial enclosed frame mixer for high-capacity dough mixing

In high-demand bakery operations, consistent and thorough...

Bulk box filler for bakery and pastry products

In the baking industry, packing small fragile products like croissants or r...

Production line for coiled bakery products

Bakeries seeking to automate the production of coiled products like croissants,...

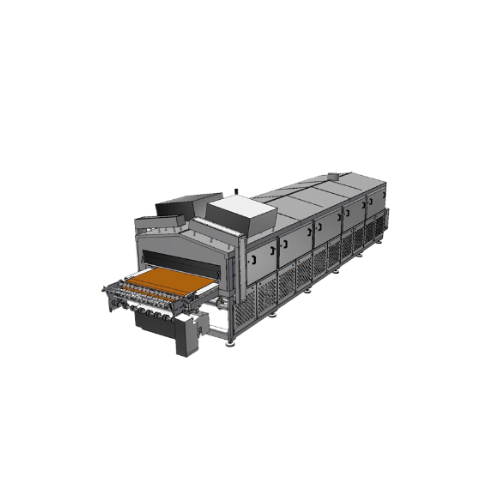

Convection oven for bakery production

In bakeries, achieving consistent and high-quality baking results is essential, parti...

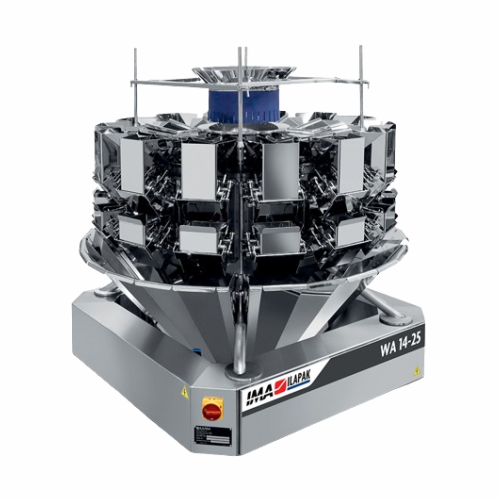

High precision multihead weigher for confectionery production

In the confectionery industry, precise weighing and minima...

Horizontal partial cut slicer for bakery products

In the bakery industry, precise and consistent slicing of products is e...

Continuous dough extruder for baked goods

In large-scale bakery operations, achieving consistent dough quality for various...

Release agent sprayer for baking trays and moulds

In industrial baking environments, ensuring that baked goods are easily...

Ultrasonic slicer for precise food cutting

In industrial and commercial kitchens, ensuring uniformity and precision in sli...

3-roll extruder for heavy dough products

When working with heavy doughs or products with particulate matter like nuts or ch...

Energy-efficient oven monitoring system for bakeries

In the bakery industry, soaring natural gas prices and strict CO2 em...

Advanced croissant production line

In large-scale bakery operations, achieving uniform quality and high production capacity...

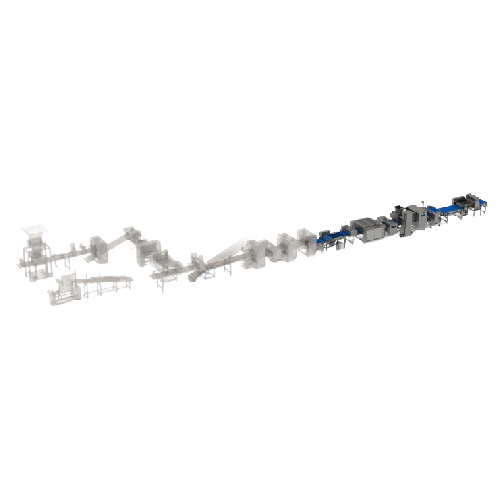

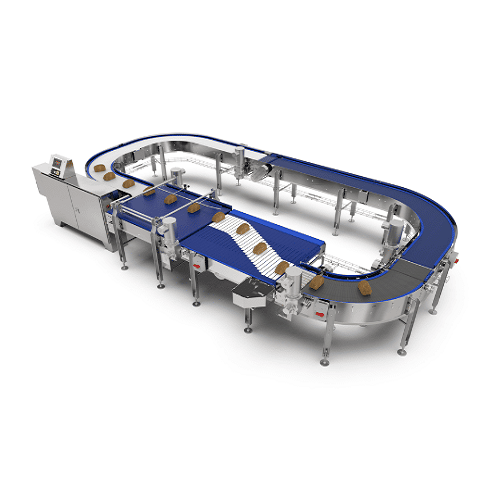

Bakery product conveying solution

In large-scale bakery operations, the seamless movement of products such as raw dough bal...

Open frame mixer for industrial dough mixing

In high-volume industrial bakeries, achieving consistency in dough quality is...

Continuous contact cooker for bottom crust treatment

In bakery production, achieving a uniform bottom crust in dough-base...

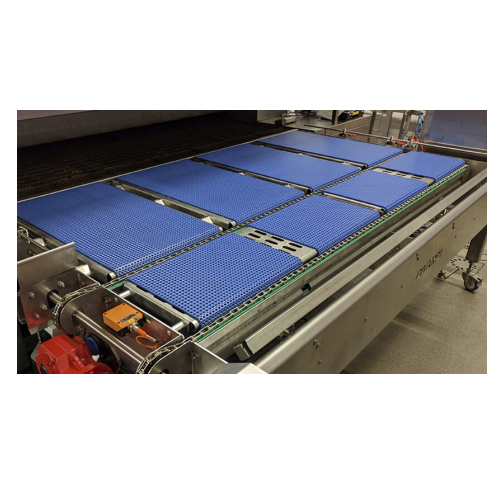

Laned product distribution for high-capacity wrappers

In large-scale bakery operations, managing high-capacity product fl...

Automated pretzel lye application system

In high-volume bakeries, manually applying lye to pretzels and other baked goods i...

Infrared oven for fast thawing and glazing

In high-demand bakery environments, speed and efficiency are crucial for meetin...

Industrial dough divider for high-capacity production

In large-scale baking facilities, managing diverse dough types with...

Sourdough fermenter for artisanal bakeries

Artisanal bakeries often face challenges in maintaining consistency and quality...

Industrial dough proofing systems

In large-scale baking operations, achieving consistent and uniform dough conditioning is ...

Commercial bakery equipment for improved baking efficiency

In modern baking operations, consistent quality and efficienc...

Moulding machine for croissant

Croissants are a popular line in commercial bakeries and are sold in high volumes. An automat...

Moulding machine for rolled bread

As great snacks and accompaniments to meals rolled bread is a staple product in commercia...

High capacity freezer for food

Freezing is one of the most important industrial methods for the long-term preservation of fo...

Industrial washer for plastic crates

In the food production sector, hygiene regulations are getting stringent by the day. E...

Cream filling machine for bakery industry

Cream and other fillings in bakery products must be injected in the right volume...

Sponge cake cooling tunnel

Exposed baked goods can develop bacteria from the circulating air in an area if left in the open ...

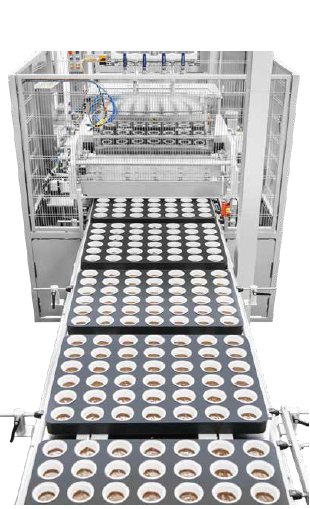

Cake batter and cream depositing machine

Whether you’re making muffins or cupcakes, you need just the right amount of...

Planetary mixer for confectionery and bakery production

For the best quality confectionary and bakery products, controlla...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

High capacity spiral proofer for pastry

Proofing is a phase in the baking production line that can’t be rushed. It’s an ess...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

High capacity spiral cooler for food

Cooling baked goods and food products can be problematic for sliced baked goods. A cru...

Washing cabinet for trolleys

Food manufacturing facilities, bakeries, or restaurants are ridden with efficiency-related issu...

Washing cabinet for food bulk containers

With an ever-increasing demand for output and stricter hygiene regulations for foo...

Industrial crate washing machine

In order to meet the increasing demand of the beverage industry, it’s essential to find a c...

Automatic pastry dough sheeter

Industrial dough sheeters turn raw dough into sheets that match recipe thickness. This includ...

ATEX confirmed outdoor silo for flour

Bulk outdoor storage of flour, dry milk and other powder ingredients for the bakery i...

Manual bag discharger for bakery industry

Many minor and intermediate ingredients for bakery products are delivered in bag...

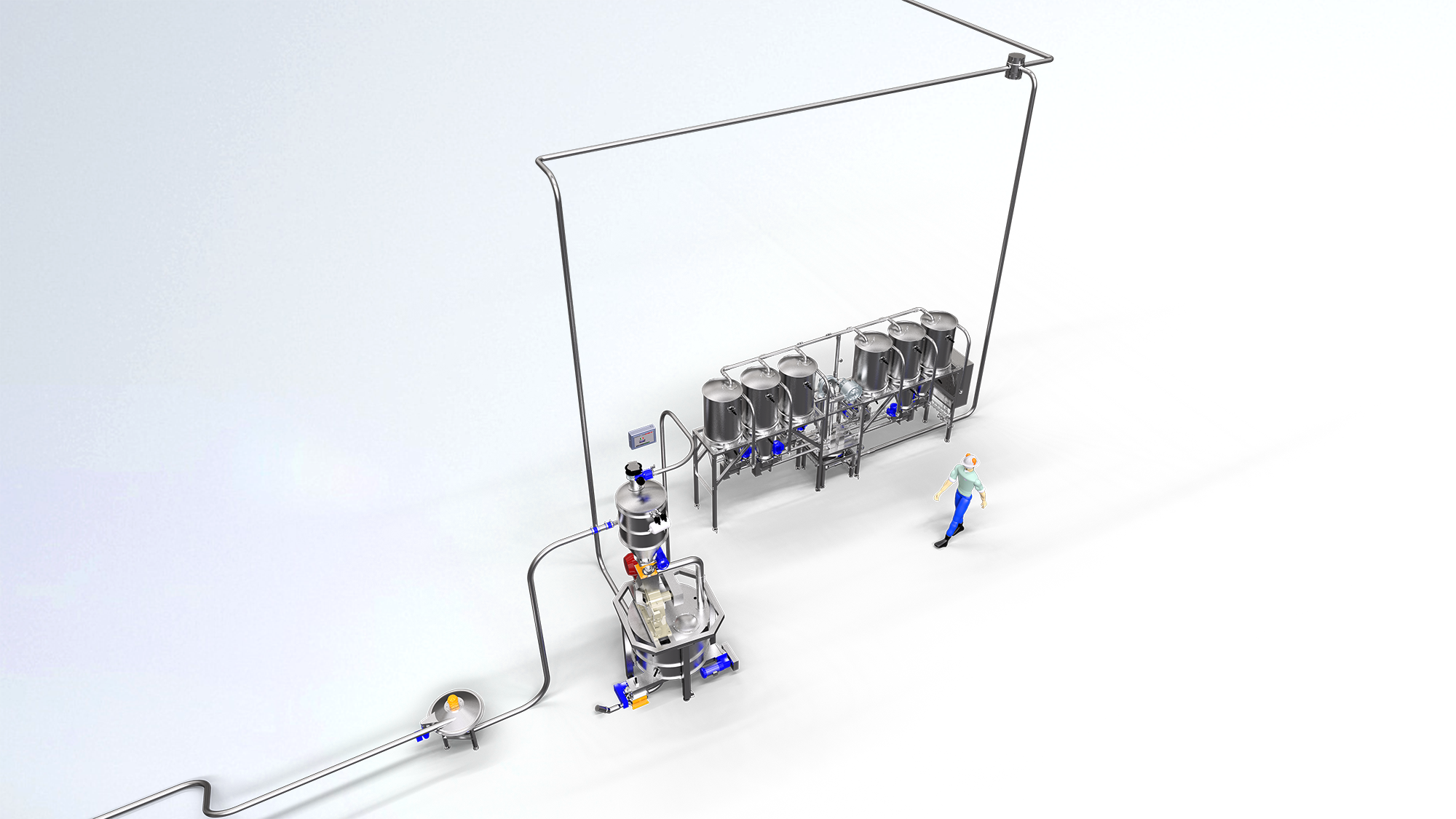

Microdosing system for bakery industry

Storage and dosing of powdered minor ingredients such as flavourings, colours and si...

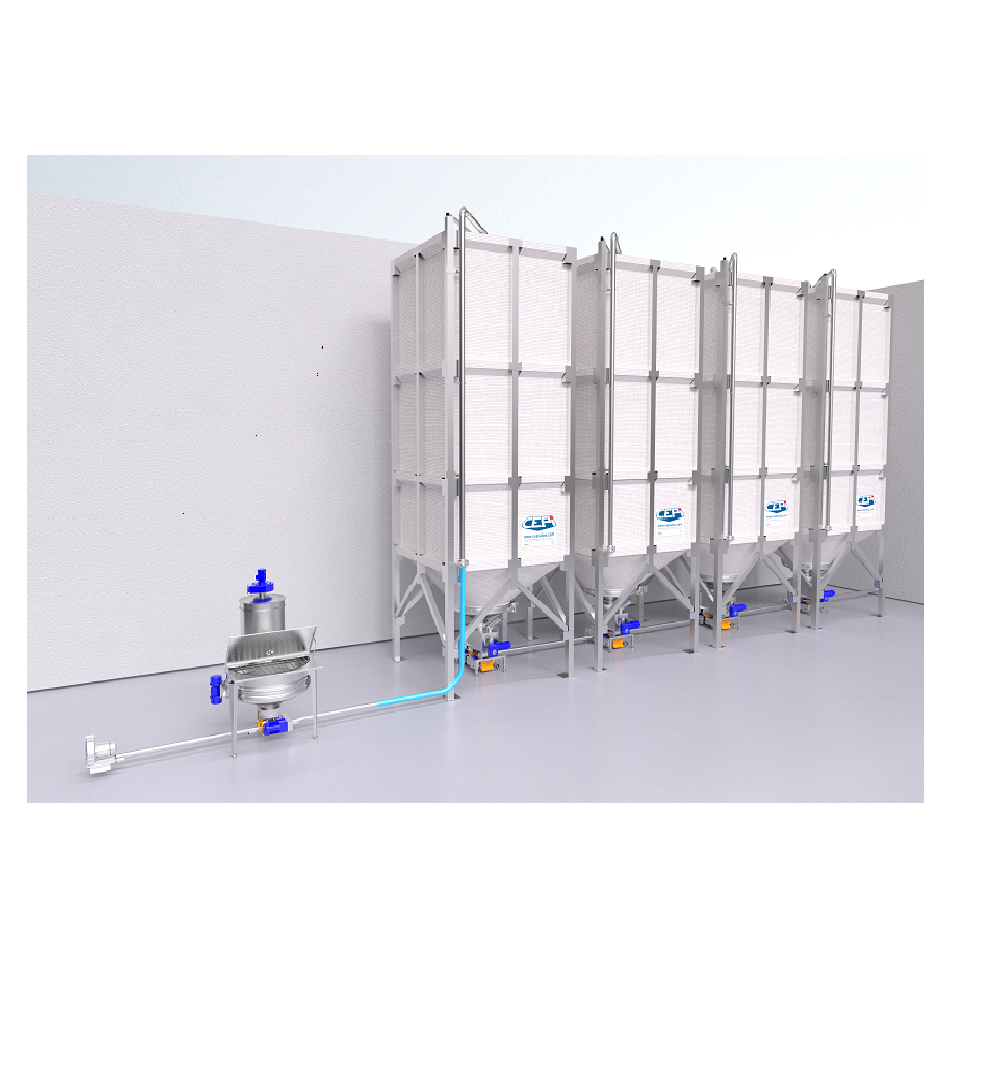

ATEX Indoor silo for sugar and flour

Storing granulated or powdered materials such as sugar and flour prior to processing r...