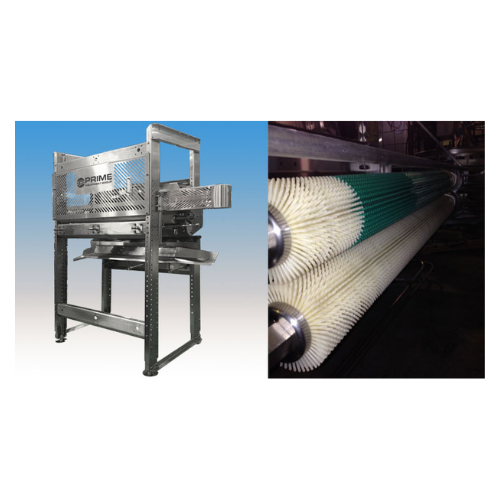

In-line paw scrubber for poultry processing

Upgrade your poultry processing line by removing ammonia burn marks and cuticle from chicken, turkey, and duck feet, enhancing product quality and maximizing yield with a cost-effective in-line scrubbing solution.

Scrubs and Cleans Poultry Feet In-Line

The ILPS-1 In-Line Paw Scrubber from Prime Equipment Group is a robust solution designed for poultry processors seeking to enhance the quality and value of chicken, turkey, and duck feet. This innovative machine operates continuously, ensuring that paws are scrubbed and cleaned of ammonia burn marks and cuticles while still in-line. Interchangeable scrubber segments accommodate various bird sizes, providing a versatile processing capability. It contributes to increased export revenue by upgrading more B-Grade to A-Grade paws, thus boosting saleable yield. The ILPS-1 integrates seamlessly with existing production lines, reducing hot water usage and dwell time in downstream paw scalder systems. Engineered for efficiency, it features a 3 HP, 208/230/460 Volt, 3-phase motor and offers variable production rates. The system’s design prioritizes sanitation and minimizes maintenance demands, supporting in-line integration for streamlined operations.

Benefits

- Increases saleable paw yield by upgrading more B-Grade to A-Grade products.

- Reduces hot water and energy consumption in scalder systems.

- Enhances line efficiency with continuous, in-line operation.

- Versatile processing for various bird sizes with interchangeable scrubber segments.

- Improves product cleanliness and market value through effective burn mark and cuticle removal.

- Applications

- Seafood,Meat,Poultry

- End products

- Turkey feet,Chicken feet (paws),Duck feet

- Steps before

- Defeathering,Evisceration

- Steps after

- Paw Grading,Paw Packaging

- Input ingredients

- poultry paws,b-grade paws

- Output ingredients

- a-grade paws,cleaned paws,paws with removed cuticles,increase export revenue paws

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Motor Power

- 3 HP

- Voltage

- 208/230/460 Volt

- Phase

- 3-Phase

- Water Connection

- 1 NPT

- Production Rate

- Variable

- Scrubber Segments

- Interchangeable for various bird sizes

- Paw Processing

- In-line continuous operation

- Automation level

- Manual / PLC

- Cleaning Method

- Sanitary design to minimize cleaning requirements

- Water Requirement

- Reduced for paw scalder machines down-line

- Abrasion resistance

- Yes

- Biological compatibility

- Food-safe materials

- Cleanability

- Easy to clean/Sanitizable

- Corrosive resistance (e.g. acids)

- Stainless Steel

- Scrubber segment size

- Interchangeable for various bird sizes

- Feed/discharge method

- In-line shackle

- Electrical specification

- 3 HP,208/230/460 Volt,3-Phase motor

- Water connection

- 1 NPT connection

- Interchangeable scrubber segments

- Yes

- Bird size compatibility

- Various sizes