Making Feed Concentrates

Find innovative production technology for making feed concentrates and connect directly with world-leading specialists

In the feed sector, it's common to talk about feed as balanced, compound, or concentrate. Many people use one of these terms to refer to any feed mill product. However, the processing of feed concentrates, only requires grinding and mixing. The further transformation into pellets adds is an added value for the market.

Select your feed concentrates process

Tell us about your production challenge

Feed concentrates tailor-made formulas to be mixed with roughages or forage

Concentrates are divided into nutrient types such as energy, protein, or feed additives. Hence the importance of mixing them with the available roughages or forage to produce a complete feed. Raising the amount of total balanced and digestible nutrients.

The standardized processing of feed concentrates caters to different livestock breeds and their life stages. But the market prices of concentrates’ ingredients are fluctuant. Thus, you need to vary your formula with accessible and affordable ingredients, maintaining the nutrient content. Also, you need to be able to develop tailor-made formulas for the farms, according to the roughages and forage available there and in the market.

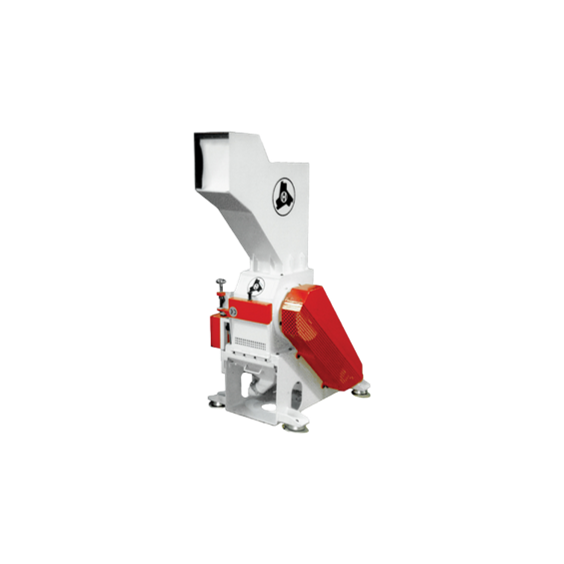

Use a hammer mill to produce mash feed concentrates

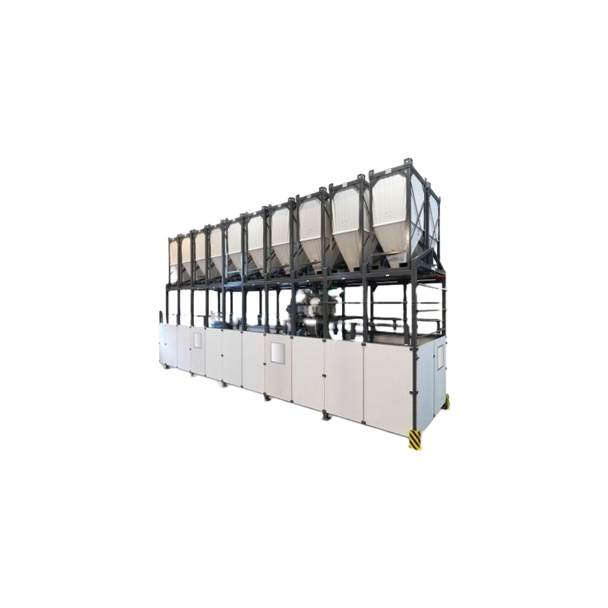

From grains to minerals to animal protein, hundreds of raw materials are suitable for preparing the feed. Depending on your formulations, the ingredients are siloed in storage units until they are ready for processing and mixing.

Grind your raw materials with a hammer mill if you are making mash feed concentrates. Combine the ingredients with a feed mixer to obtain a homogeneous formula. In the case you want to add value to your product, you can finish by using a pellet mill.

Formulate feed concentrates according to the nutritional value

Having the equipment and the raw material is not enough to make concentrates. You need to know each ingredient’s nutritional value. Also consider the nutritional needs of the targeted livestock depending on their stage in life. Then at the farm they will get the mix to balance and complement as require.

Processing steps involved in feed concentrates making

Coating

Containment

Conveying

Cooling

Crushing

Drying

Extrusion

Feeding

Filter presses

Flexible intermediate bulk containers

Formulation

Granulation

Grinding

Industrial checkweighers

Industrial hammer mills

Industrial hoppers

Measurement & Control

Milling

Mixing

Pelleting

Pelleting Presses

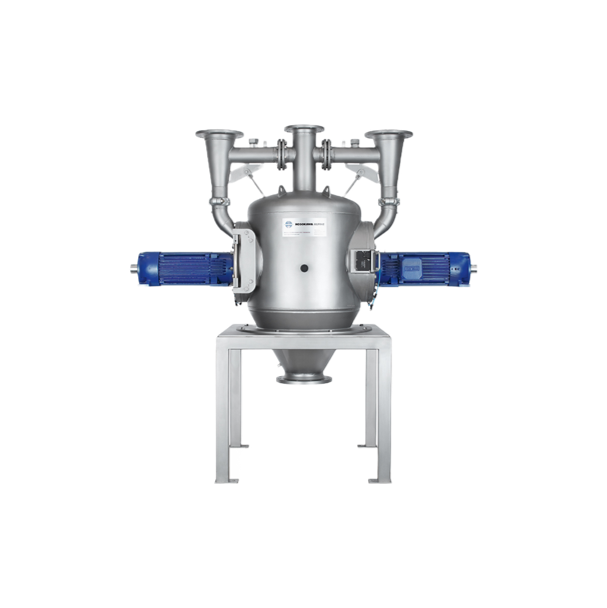

Sieving

Silos

Which feed concentrates technology do you need?

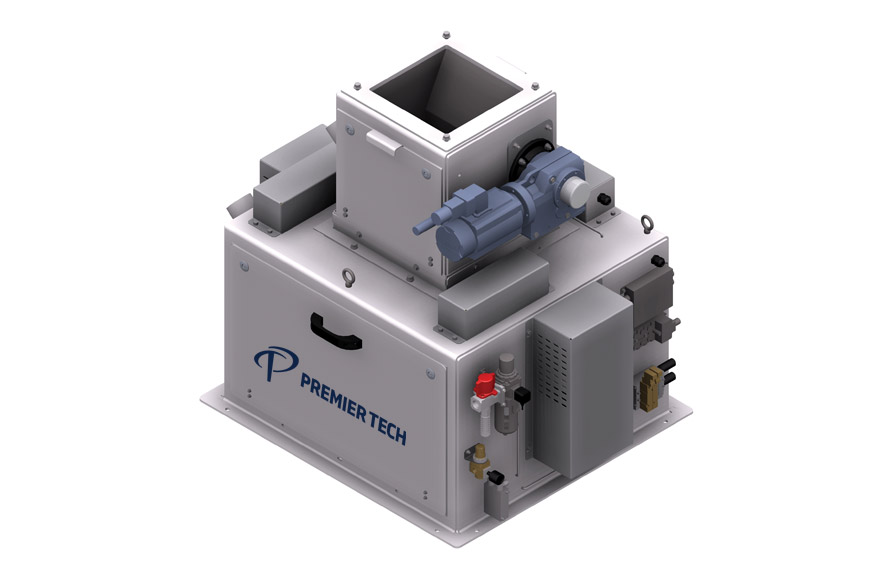

Double shaft paddle mixers for industrial powders and granulates

In the production of feed, pet food, aquafeed, and prem...

Screw conveyors for grain processing and feed mills

In grain processing and feed mill operations, efficient material hand...

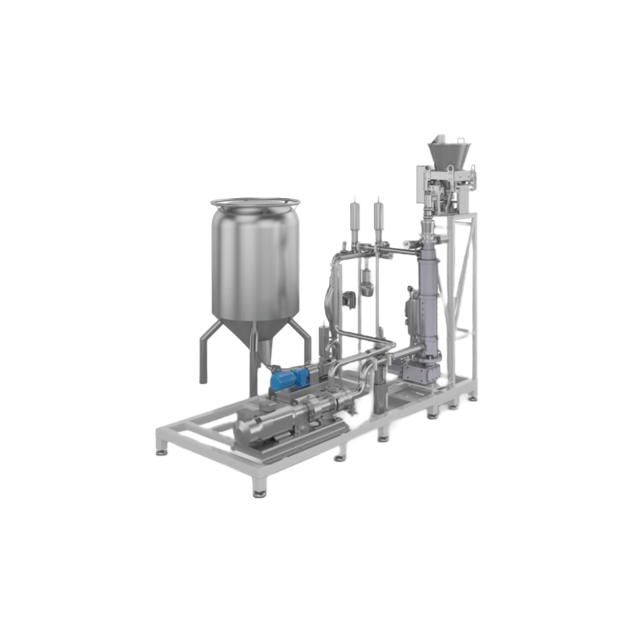

Continuous coater for pellet and extrudate liquid addition

In the production of animal feed, ensuring that liquids such ...

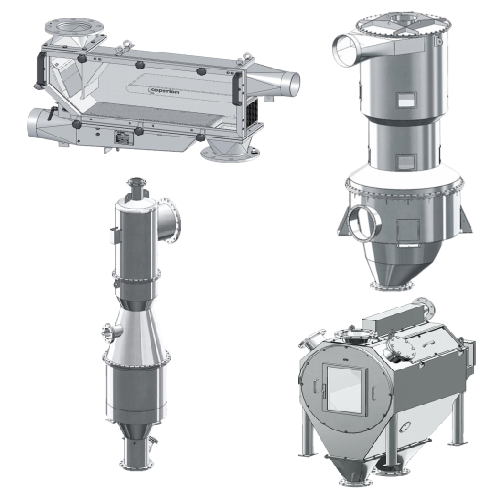

Pellet dedusting elutriators

When processing bulk materials, maintaining the purity of pellets is essential to ensure high-q...

Pulverizer for fine grinding applications

In industries such as food processing, chemicals, and pet food production, achie...

Big bag loading station for bulk product handling

Handling large quantities of bulk products efficiently and safely is a ...

Industrial rotary dryer for high moisture content materials

In the process industries, dealing with materials that have ...

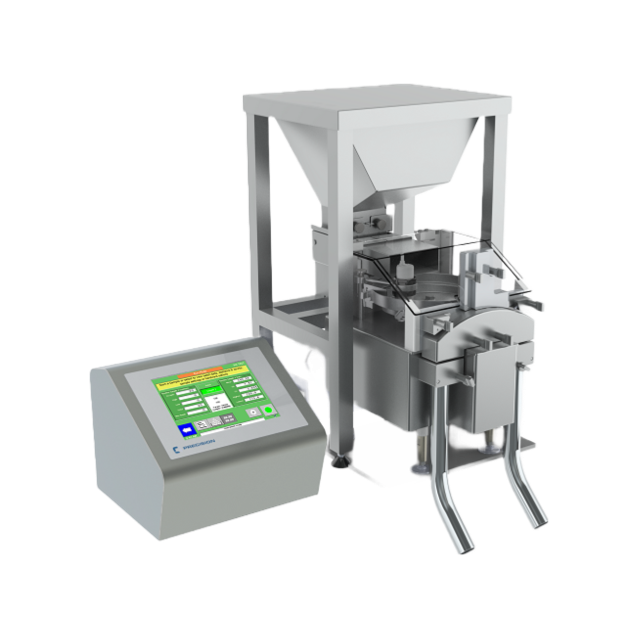

Single feeder operator interface for gravimetric feeders

In industries requiring precise material dosing, managing a grav...

Energy efficient steam dryer for feed products

Traditional drying technologies with low investment cost, such as hot air d...

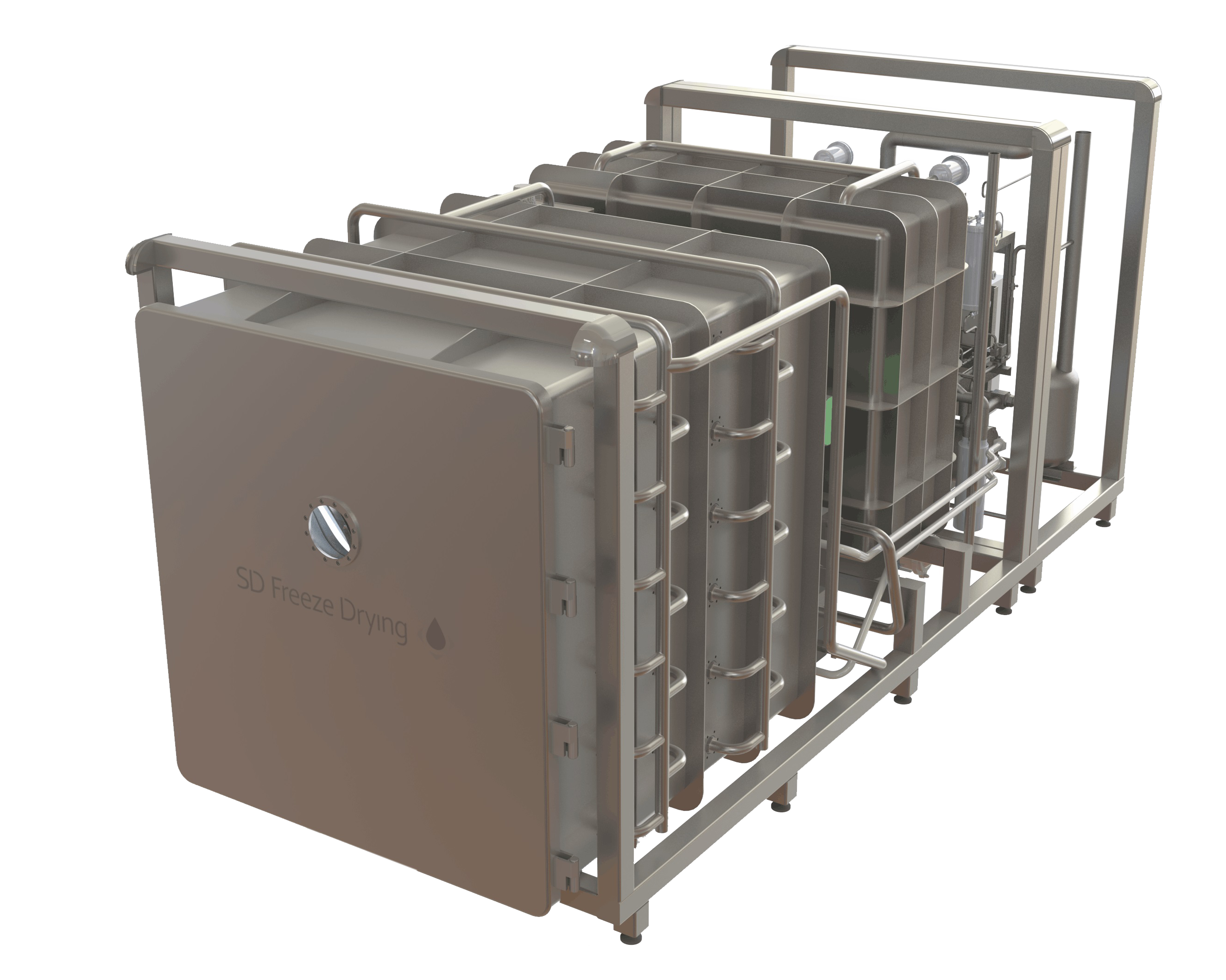

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Automatic palletizer machine for bags and boxes

The effective placement and positioning of bags and boxes can be a challen...

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Form fill seal bagging machine

If you are in industries such as petrochemicals, fertilizers, animal feed, food, etc, you mus...

Vertical form fill seal machine

There is an increasing demand for a range of different package sizes of the same product. If...

Robot palletizing system

If you are a relatively large-scale producer, packing and transporting large quantities of products ...

Automatic bag slitter

Unacceptably high dust levels can be generated whilst manual emptying and handling of bags, also produc...

Pelleting press for feed and petfood

The production of agricultural feed and pet food products requires machines and plants...

Stretch pallet hooder

Palletised loads need to be securely wrapped in order to protect them from shifting, crushing, ripped o...

Vertical form, fill and seal machine for bags from 5 to 50 kg

To securely create, dose and pack larger quantities of mat...

Big bag solutions

Management of big bags requires specialist handling and selection of cost-effective configurations for fill...

Hygienic FIBC handling line

There are many considerations when handling FIBC’s (Flexible Intermediate Bulk Containers)...

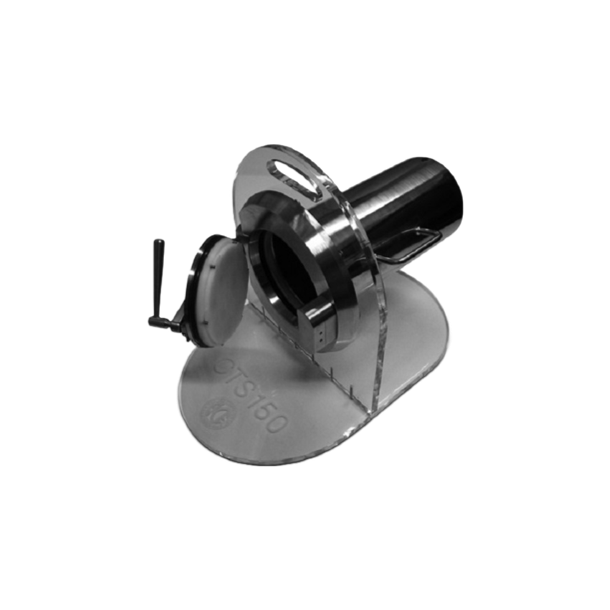

Light duty rotary dust valve

In some light industrial applications there is limited pressure differential for valve operation.

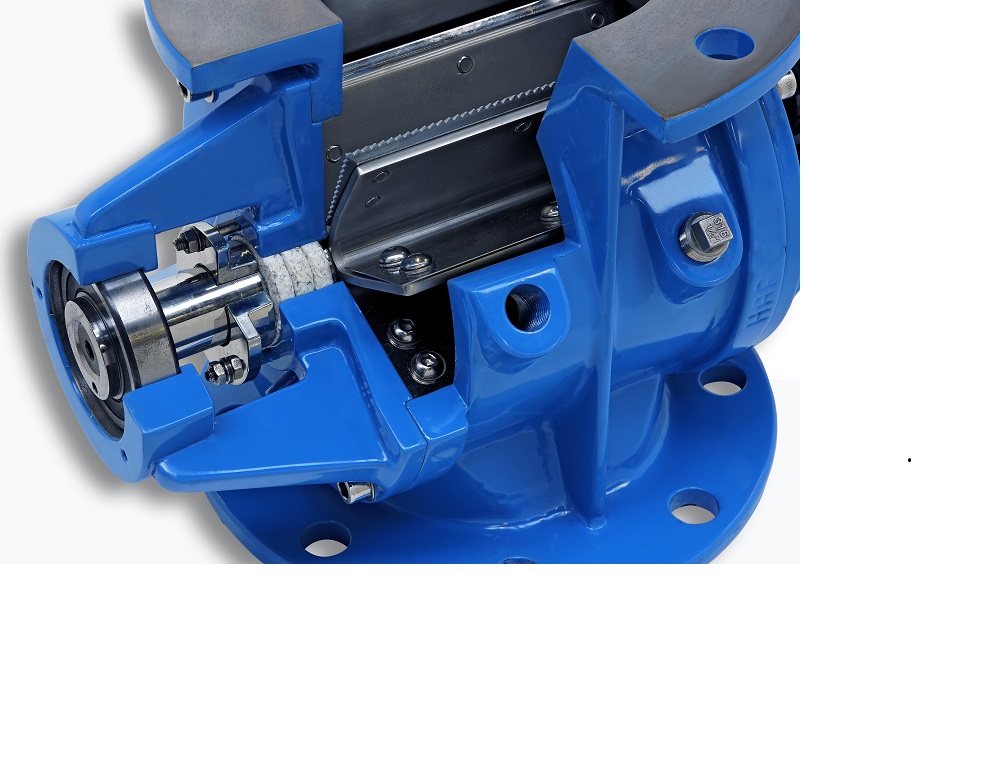

Heavy duty rotary valve

Handling powdered and granulated materials in pneumatic conveying systems requires consistent, safe v...

Dual channel plug diverter valve

Short switching times are often required when diverting or combining powder or granular sol...

Two-way flap type diverter valve

Routing powder, pellets or granules from a product source to two receiving points must be d...

Electronic net weigher for high-capacity baggers

Electronic net weigher raises the industry’s standards to a higher level ...

Compact palletizer

Choosing an accurate palletizer can be quite an advantageous move. This one is designed for euro, industri...

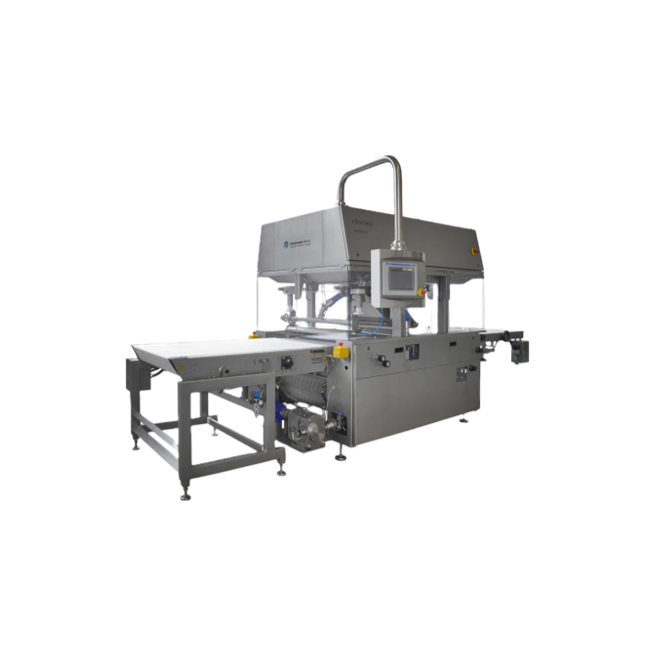

Hygienic open-mouth bottom-up baggers

Here are the open-mouth baggers that are specially designed for hygienic bagging of p...

Short path evaporators

With short path distillation, a substantial decrease of boiling temperature is obtained by reducing th...

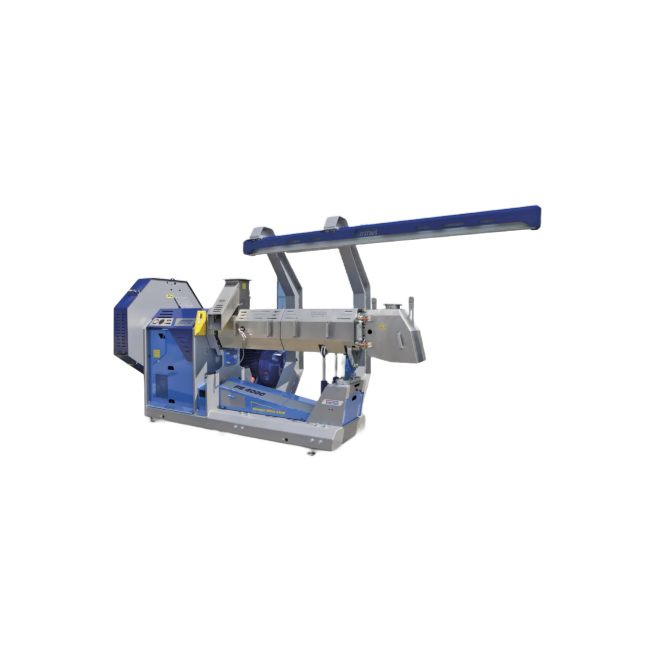

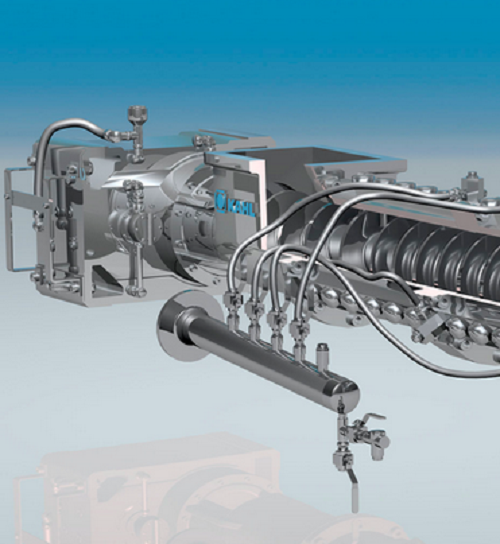

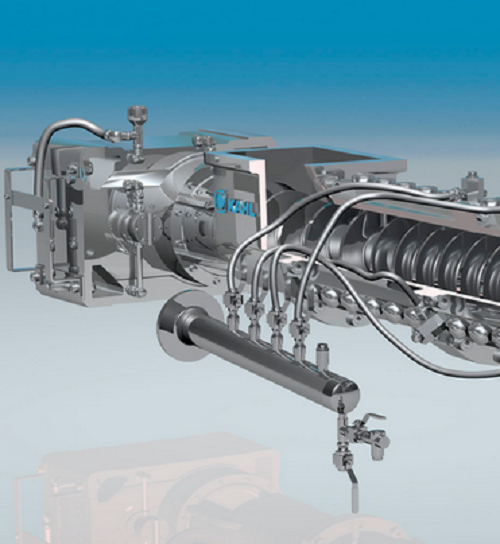

Extruder with annular gap expander

Products can be extruded with various shapes and characteristics by controlling the nozz...

Laboratory extruder

Products can be extruded with a variety of shapes and characteristics by controlling the nozzle geometry ...

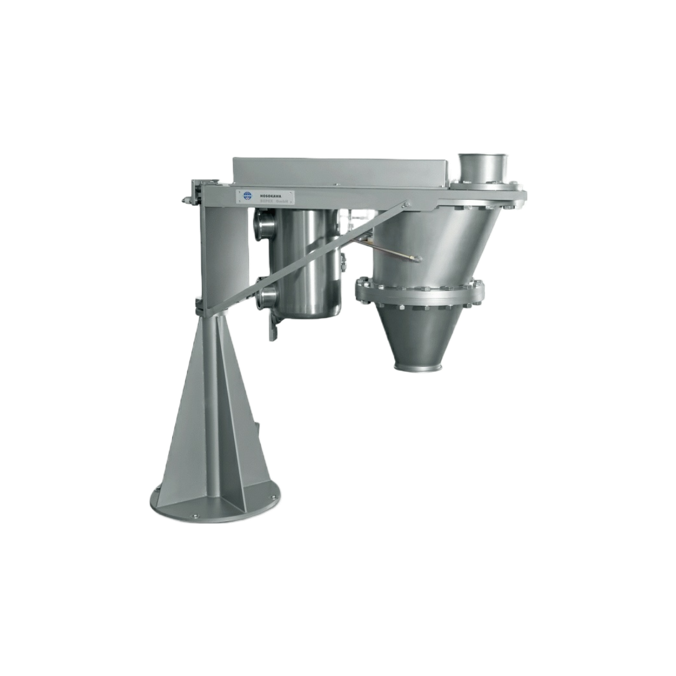

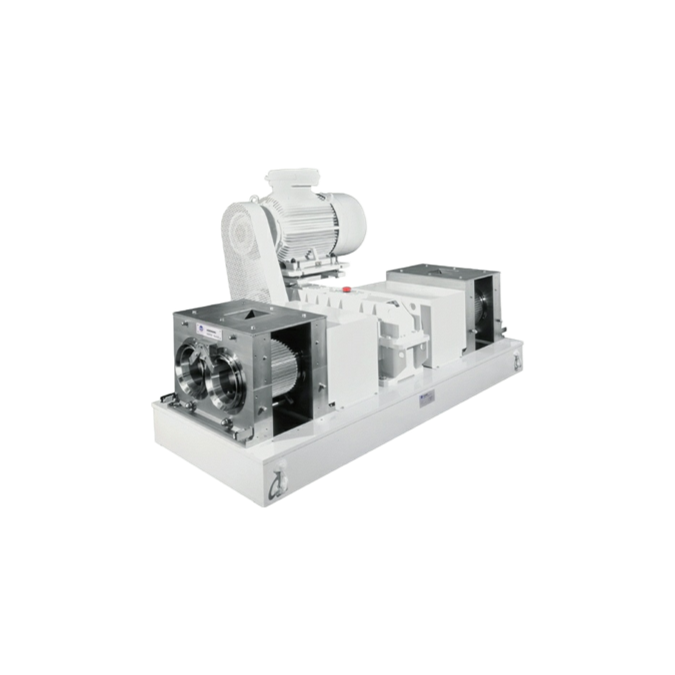

Annular gap expander for compound feed

Compound feed processing often requires a means of kneading and mixing input substra...

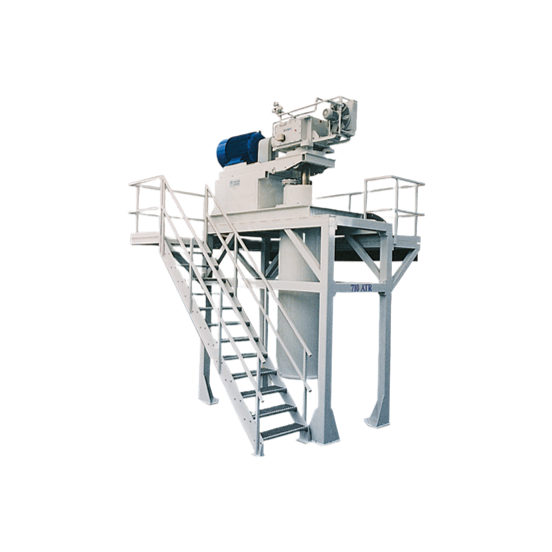

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

Hygienic pelleting press

The production of pelletized or granularized food products requires hygienic presses designed for hi...

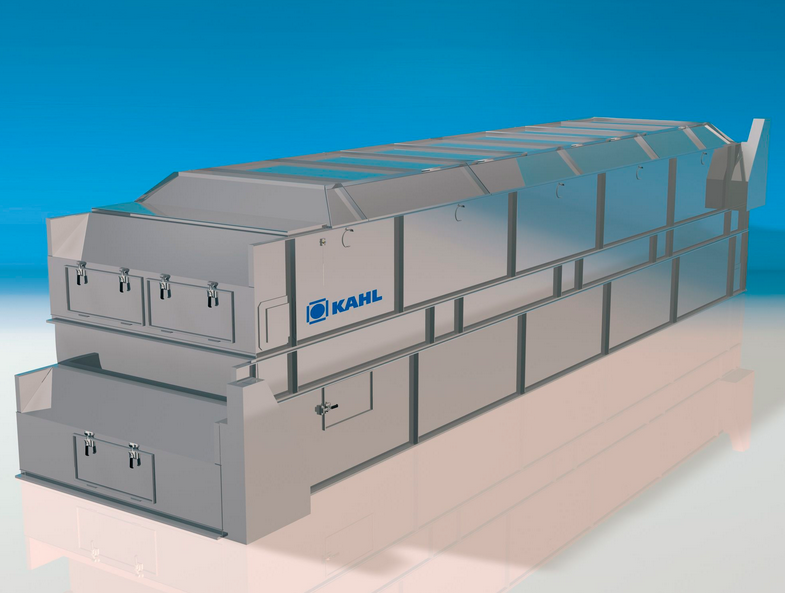

Belt dryer/cooler for pellets and granules

Many industries that process materials in pellet, powder, or crumble form need ...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....