Ketchup Processing Equipment

Find innovative production technology for making ketchup and connect directly with world-leading specialists

Ketchup processing begins with tons of tomato paste that is mixed and heated together with sugar, vinegar, and spices in a cooking kettle. After cooking, any remaining fibers and particles are filtered out. Once it reaches the right viscosity, your tomato ketchup production process is finished and ready for packaging and transport.

Select your ketchup process

Tell us about your production challenge

Converting fresh tomatoes into a tomato puree

The first thing you need is tomato paste. It’s usually bought as an ingredient due to the seasonal nature of tomatoes. But, if you are processing the paste too, fresh tomatoes first need to be washed in rotating drums, sorted and cut them into smaller pieces. To remove the tomato seeds and the skin from the pulp, the tomatoes must go through a pulping machine and then the resulting pulp has to be filtered through screens. Tomatoes then go to an evaporator which involves a hot break treatment unit that includes heating them at a temperature of 90˚C or higher. The hot break step is a core process for enzymatic inactivation to preserve the pectin.

Ketchup – The Asian’s origin you don’t expect

Kê-tsiap, that’s the original name of our beloved table condiment, comes from southern China, and, here ye, at first it was tomato-free. It was a sauce made with fermented fish. After a long journey through England and America, the recipe of the tomato-based ketchup we know came to us. But how is it made?

From paste to ketchup – what processing equipment is required?

Tomato paste arrives vacuum-packed in large storage bins, ready for further processing lines. After quality control, and making sure there are no residual tomato seeds, you can move it to a cooking kettle for a second heating treatment where you can add different spices, vinegar and sugar. An industrial cooker mixes all the ingredients and heats them to the desired temperature. The ketchup mixture is filtered to remove fibers and particles and a homogenizer is then used to achieve the right consistency. A de-aerator can help you to get rid of the air stuck into the tomato ketchup which reduces the risk of bacterial growth and discoloration. Before moving to a filling line a final check is done on the viscosity in order to make sauce with the perfect texture.

A viscometer to analyse your ketchup's consistency

Have you ever noticed that if you turn a bottle of ketchup upside down nothing happens unless you shake it? Ketchup is made of tomato pieces suspended in a liquid that, by touching each other, create a network that can resist motion as long as you apply the right amount of force to it to make it flow. With a viscometer you can analyze how fast the tomato sauce travels and what is the viscosity. Studies have shown that the correct flow speed is 0.045 km/h or 0.028 miles/hour.

Using a hot fill solution for your ketchup bottles

Before filling, ketchup should be heated to no less than 88°C to avoid contamination. During the hot filling, both the product and the container are sterilized by heat. Hot ketchup is injected into a container that is then kept at high temperatures for a period of time to ensure that there are no bacteria in the food or in the packaging. After hot filling, ketchup should be cooled immediately to preserve the taste and flavor. Although hot filling of ketchup is considered safe for the shelf life, some manufacturers choose to perform a pasteurization process (another heating treatment) at 85-88°C.

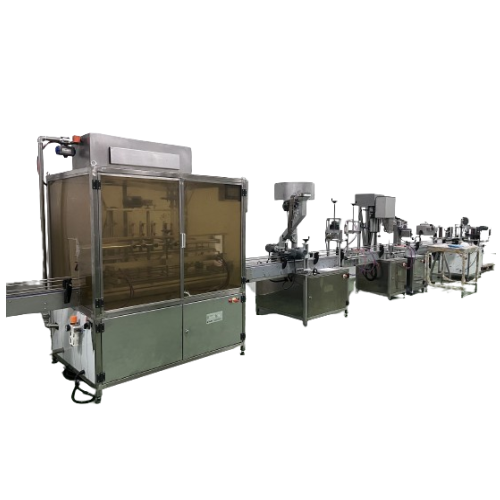

Cap and close your ketchup bottles after filling

You can choose to pack your ketchup in pouches, sachets, tubes, or bottles and it’s important to close your package quickly after filling to avoid contamination or spilling. Capping or other closing systems such as seals are often installed in the same filling system. When filling glass or plastic bottles containers in line, crew caps, lug caps or snap-on are placed after filling up to the desired weight or height.

Processing steps involved in ketchup making

Which ketchup technology do you need?

High shear emulsifier for food and pharmaceutical products

In the production of emulsified products such as mayonnaise, ...

Pouch cooling system for food processing

In the food processing industry, rapidly cooling hot-filled soups, sauces, or chow...

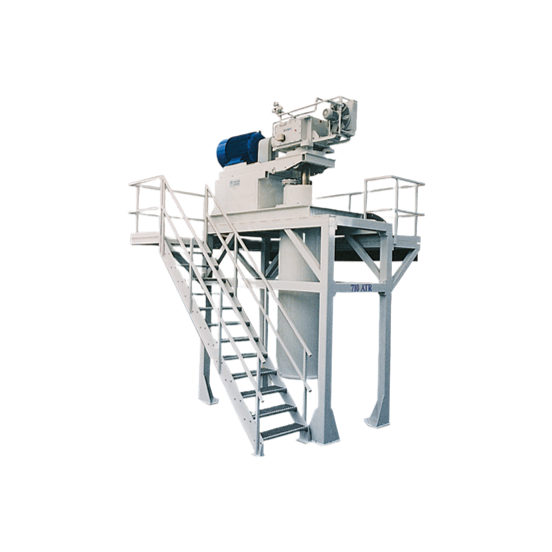

Blender for high viscous products

When producing high viscous products such as ketchup, mayonnaise, or creams, traditional ...

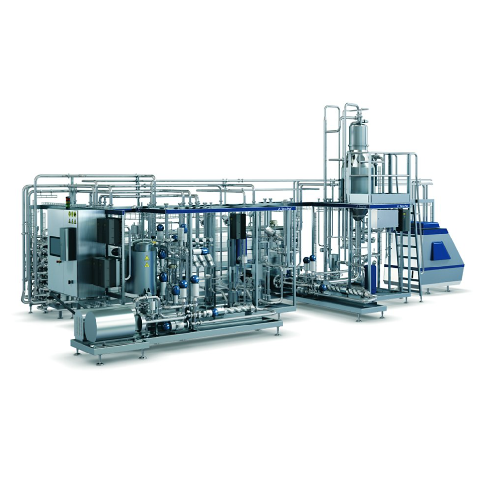

Ketchup and sauce processing line

Producing consistent batches of ketchup, sauces, and culinary compounds in both retail an...

Scraped surface sterilizers for food industry products

In the food industry, processing products like ketchup, sauces, da...

Liquid food filling solutions

When producing liquid food products in large volumes, it’s crucial to ensure hygienic, e...

Tunnel for thermal treatment of packaged foods and beverages

In food and beverage production, ensuring optimal thermal t...

Industrial cooking kettles for food processing

In the food processing industry, achieving consistent quality and efficienc...

High-precision rotary weight filler for edible oils and sauces

Achieving consistent filling precision and minimizing pro...

Top load and side load case packer with vision guided robotics

In secondary packaging, optimizing the process requires e...

Scraped surface sterilizer for high viscosity liquid products

In the production of aseptic preparations, ensuring the st...

Ketchup production line

In the food industry, producing high-quality ketchup and vegetable sauces involves handling diverse r...

Industrial homogenizer for food and beverage applications

In the production of food and beverage products, maintaining a...

Scraped surface heat exchanger for viscous products

When producing high-viscosity products like ketchup, mayonnaise, or p...

Scraped surface heat exchanger for high-pressure applications

In industries where continuous processing of high viscous ...

Customizable sanitary conveyor systems

In many industrial settings, transporting materials efficiently while maintaining hy...

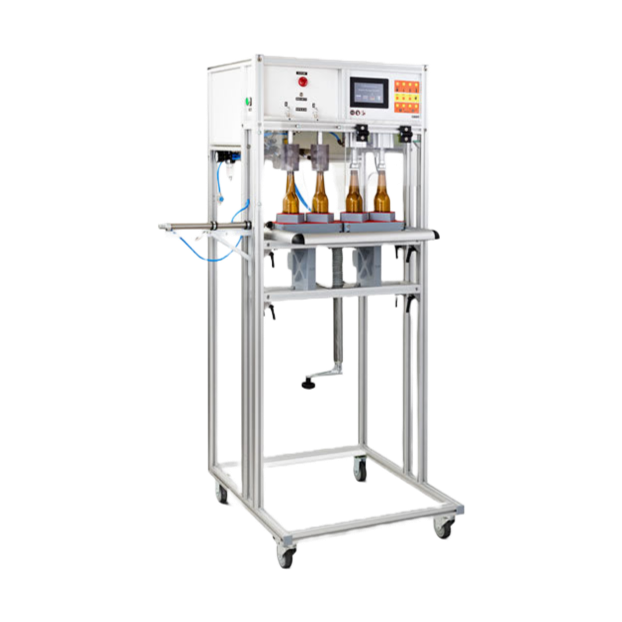

Semi-automatic overflow liquid filler

In industries where low to medium viscosity liquid filling is required, maintaining a...

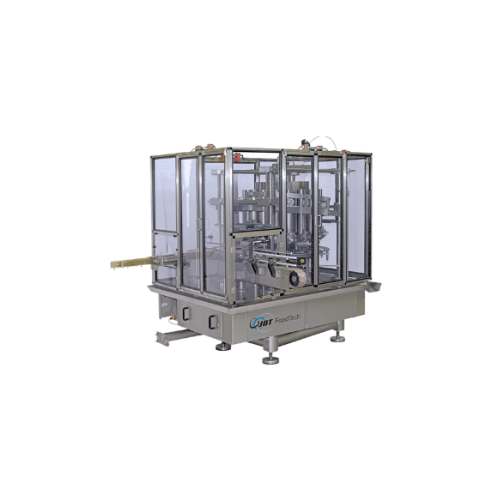

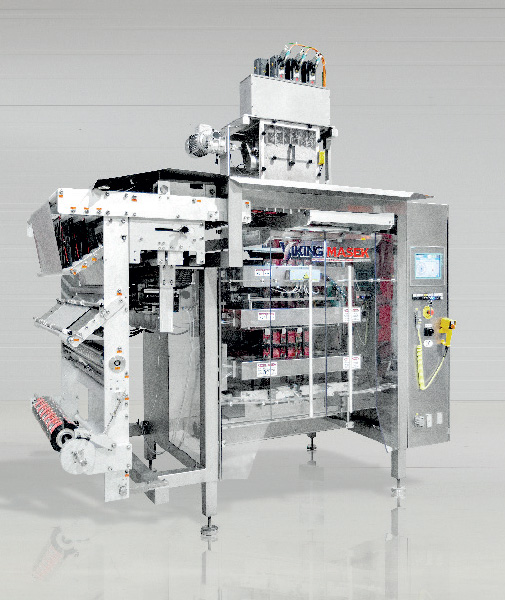

Form, fill, and seal system for single-use pouches

When producing single-use pouches for products like ketchup, lotions, ...

Volumetric piston filler for liquid and viscous products

In food processing, maintaining the accuracy of filling liquid o...

Rotary gravity fillers for diverse liquid products

In food and beverage production, the challenge of filling various liqu...

Rotary piston fillers with plunger for viscous products

In food processing and other industries, handling and filling vis...

Viscous and liquid product processor

In industries such as food processing and pharmaceuticals, refining or finishing free-...

Continuous sugar dissolver for beverage and food production

In industries like beverage and food production, achieving p...

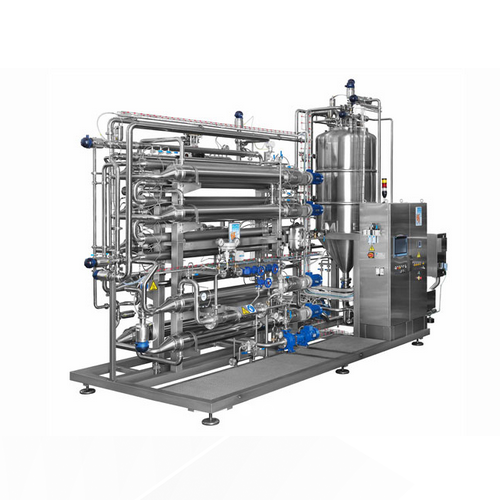

Food pasteurizer for prepared foods

In the food processing industry, ensuring the safety and shelf-life of prepared foods l...

Efficient pasteurizer for prepared foods

When producing prepared foods like sauces, desserts, and fruit preparations, the n...

Tomato paste processing line

In the food industry, especially for condiment manufacturers, there is a need to efficiently pr...

Ketchup manufacturing line

In the food production industry, creating high-quality ketchup efficiently and in large quantitie...

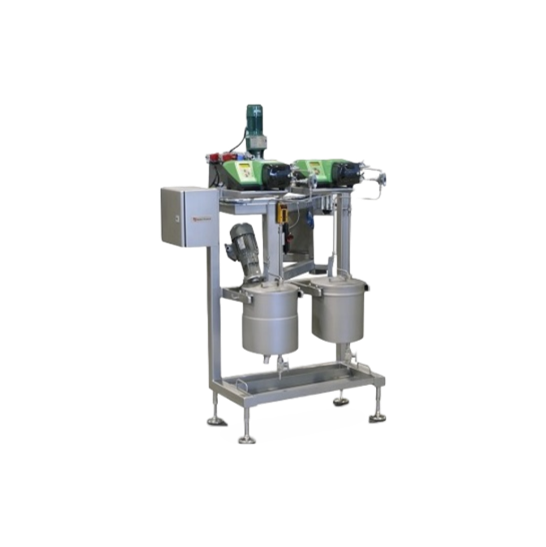

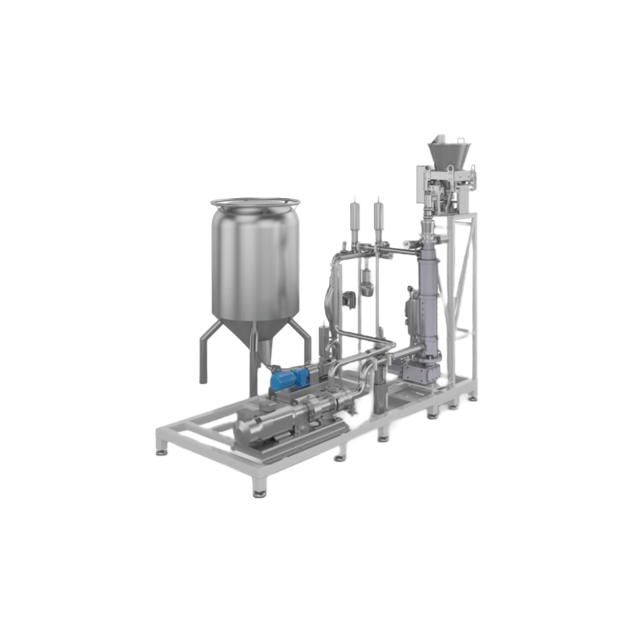

Vacuum process system for food product mixing and emulsifying

Creating food products like mayonnaise, ketchup, and dress...

Industrial Sauce Homogenization and Emulsifying System

Texture and consistency are critical to foods with delicate compos...

Homogenization and emulsifying system for fine foods

Texture and consistency are critical to foods with delicate composit...

Marmalade and Jam Processing Machine

When producing jams and marmalades, preserving the natural flavours, aromas and colors...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Shrink wrapping machine for PET bottles

During a shrink-wrapping process, a change of reel can slow down the production cyc...

Jam pasteurizer with temperature control

Microorganisms and pathogenic forms in fresh fruit jams can shorten storage time. ...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Automatic filling machine for sauce

Traditional sauce filling units can struggle to maintain a high quality of output in ca...

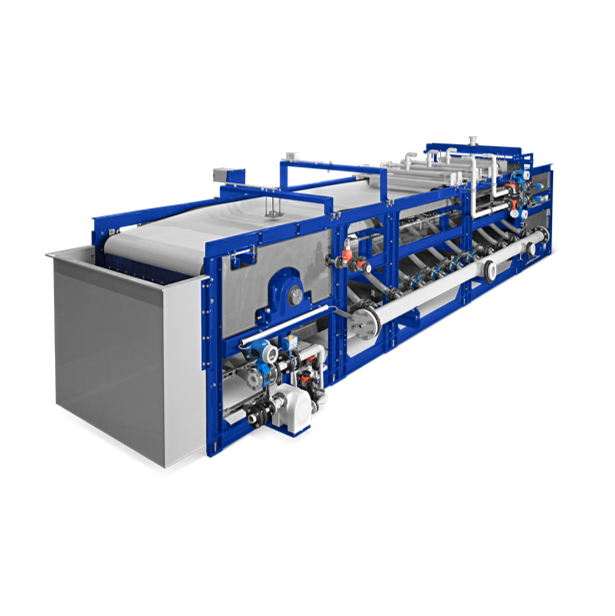

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

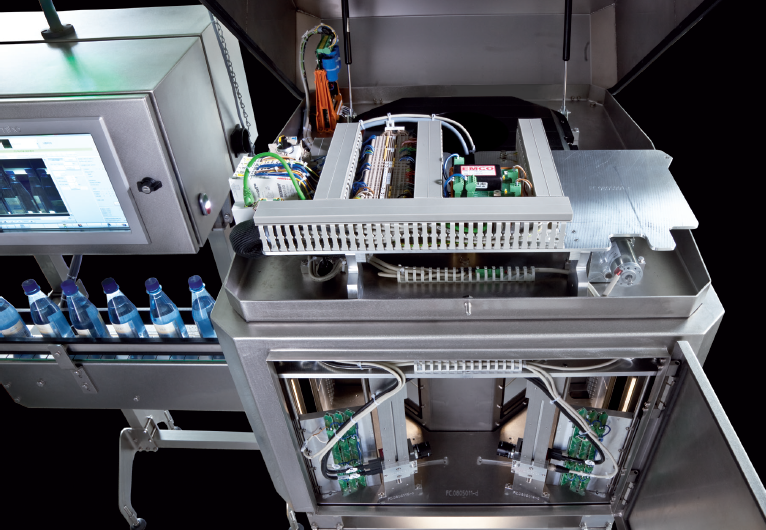

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

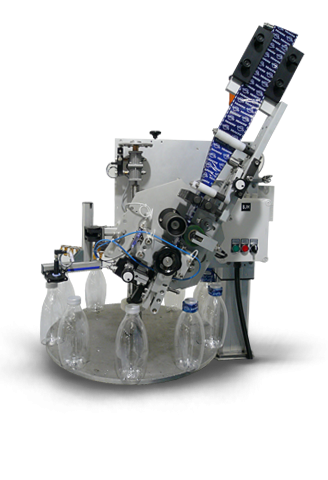

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

In-line tamper evident applicator head

Integrating tamper protection equipment into an existing production line means addit...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

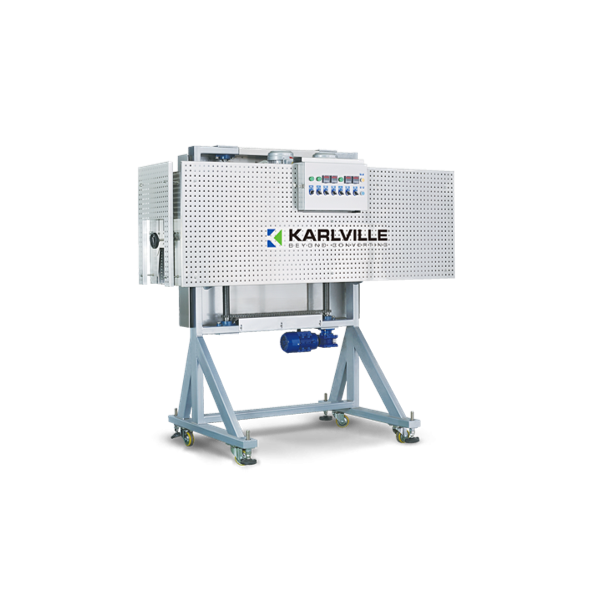

Advanced auto-steam shrink system

Design and development of shrink sleeves could be made much easier if small batches of sa...

Premium steam tunnel for sleeve application

Maximum flexibility in terms of pressure, temperature and ramp setting and adj...

Shrink tunnel for applying sleeves to different containers

Maximum flexibility is required when setting pressure and dir...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...

Energy efficient tunnel for sleeve application

Hot air application of shrink sleeves is much more efficient than tradition...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...

Smart Industrial Sauce Cartoning System

Large volume producers of sauces and ready meals continuously pack different produc...

Batch processing system for emulsions and suspensions

Emulsions enhance foods with a creamy mouthfeel and richer flavors....