Making Lip Gloss

Find innovative production technology for making lip gloss and connect directly with world-leading specialists

Invented in 1930 by Max Factor to give movie actresses' lips a brighter, more glossy look, lip gloss is a must-have for kids and adults alike. If you think about it, it's the first makeup product a little girl plays with. Making lip gloss involves the use of lip gloss making equipment for several steps such as melting, mixing and packaging.

Tell us about your production challenge

Lipstick vs. lip gloss: same ingredients, different result

Looking at the formula of lipstick and lip gloss, you can easily see that they are composed of the same ingredients, i.e., waxes, oils, and pigments. So first you have emollients such as lanolin that prevent moisture loss and give the gloss you look for; then waxes such as carnauba wax and beeswax that help the gloss stick to your lips; and last but not least, pigments. But the end result of lip gloss (sheer and shine coverage to the lips) is totally different from lipstick.

So where’s the trick? The difference is all in how the ingredients are distributed in both products. A lip gloss contains a higher percentage of oils and a lower percentage of waxes and pigments to give a wet texture and a shiny look to your lips. Plus, the pigments used in lip gloss are often diluted and have a pale color.

How to make lip gloss using lip gloss making equipment?

The lip gloss making equipment covers three different steps: melting, mixing and packaging. Firstly, the waxes and oils are heated separately in process vessels and then combined in a mixer. The powdered pigment is dispersed into a portion of the oil in a conventional mill. This is later added to the oil-wax phase and mixed uniformly in a colloid mill to achieve a smooth consistency. After cooling, you can add fragrances, preservatives and other ingredients.

Finally, you can pack your lip gloss into plastic tubes. The filling machine continuously mixes the lip gloss to maintain its consistency, thus avoiding lumps during the filling process. Electronic control enables automatic loading and screwing of the brush applicator, built into the tube cap, and the finished product is ejected automatically.

The underlying chemistry of colour-changing lip gloss

Did you know that there is a magical lip gloss that actually changes its color when you moisten it with your saliva? The Institute of Personal Care Science explains how this lip gloss is made and how the color change occurs.

This lip gloss formulation employs polar esters as holder lipids, consistency modifiers to give the viscosity and citric acid to make it acidic. However, our magic ingredient is bromo-acid colorants which are pH-changing colorants. The lip gloss remains in an acid medium until it’s applied to your lips; but as soon as you lick your lips with your saliva, which has a pH of about 7, the lip gloss gets neutralized and surprisingly changes its color on your lips.

How do lip-plumping glosses work?

A lip plumping gloss is a cosmetic that gives a plumping effect to your lips. The lip-plumping glosses can be formulated in two ways. One category of lip plumpers contains chemical irritants that tend to sting the lips, which in turn prompts the flesh of the lips to fill with more blood and become slightly puffy or swollen.

Some such lip plumpers actually contain natural chili pepper extracts and aid the irritation action due to the presence of capsaicin in the chili peppers. Another category of lip plumpers contains hydrophilic ingredients which are absorbed by the skin of your lips, where they fill with moisture and swell, thus giving you fuller lips. Lip plumpers are available in different colors and usually contain light-reflecting materials like mica which shimmer and add to the visual effect of lip fullness.

Processing steps involved in lip gloss making

Which lip gloss technology do you need?

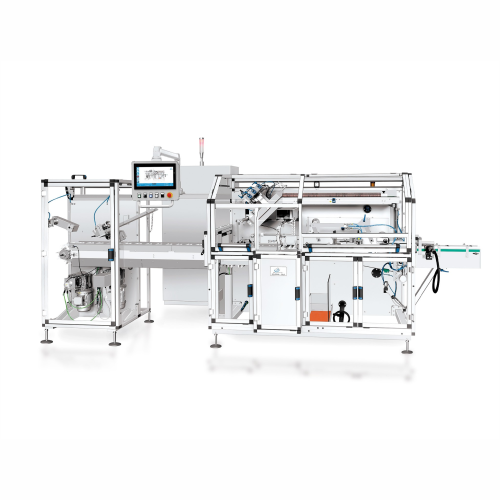

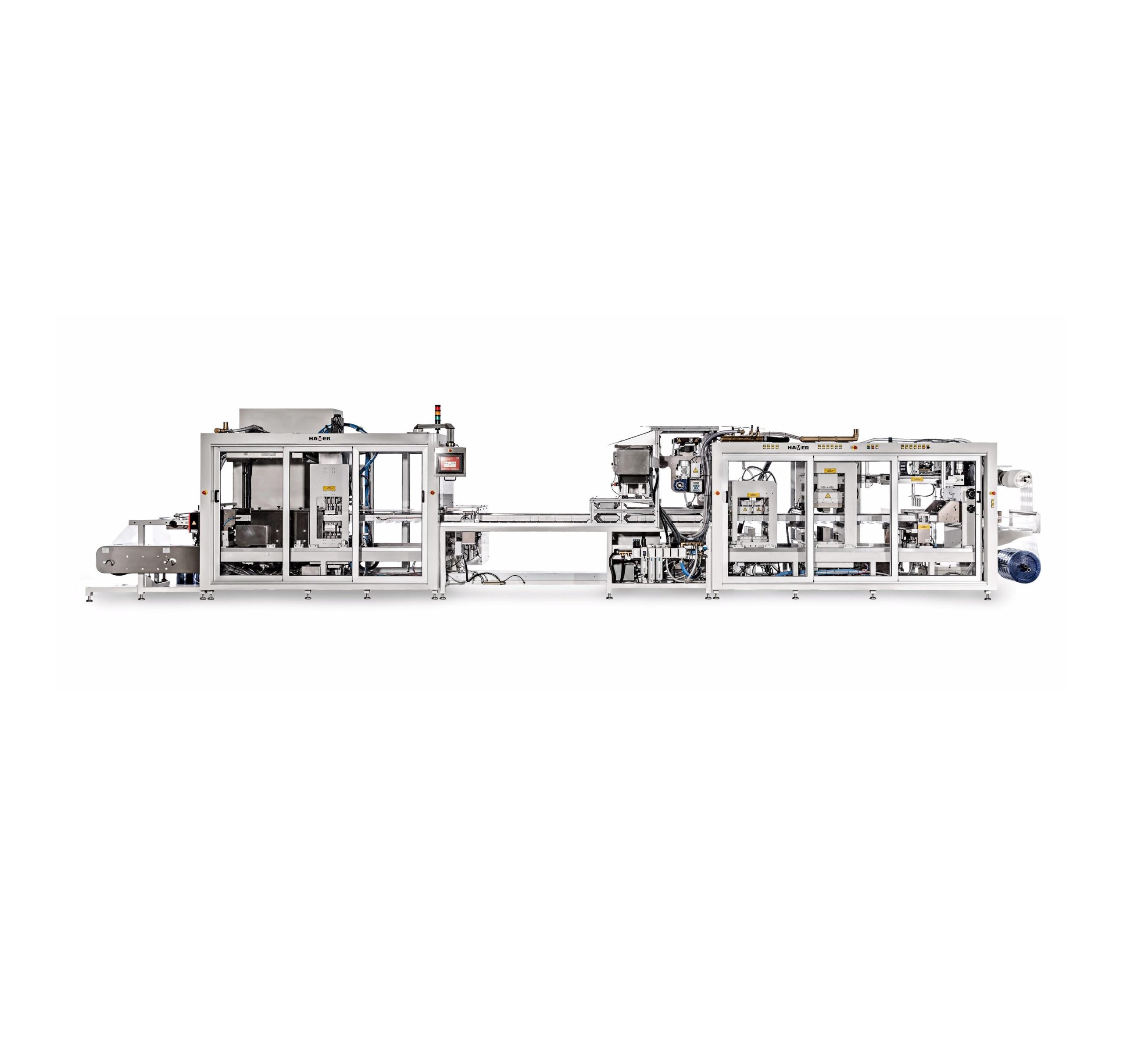

Automatic horizontal cartoning solution

In the beauty and cosmetics industry, efficient and precise cartoning is crucial wh...

Automatic horizontal cartoning solution for various products

In the packaging industry, efficiently and accurately carto...

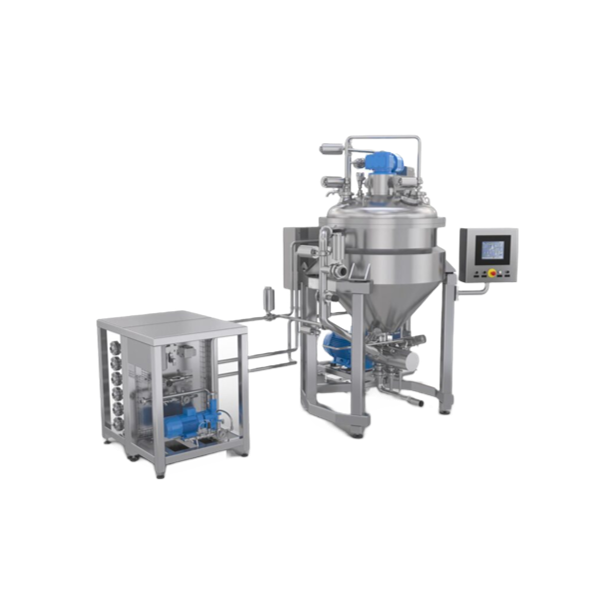

Industrial melter for cosmetic product processing

In the cosmetics industry, the precise heating and mixing of oil and wa...

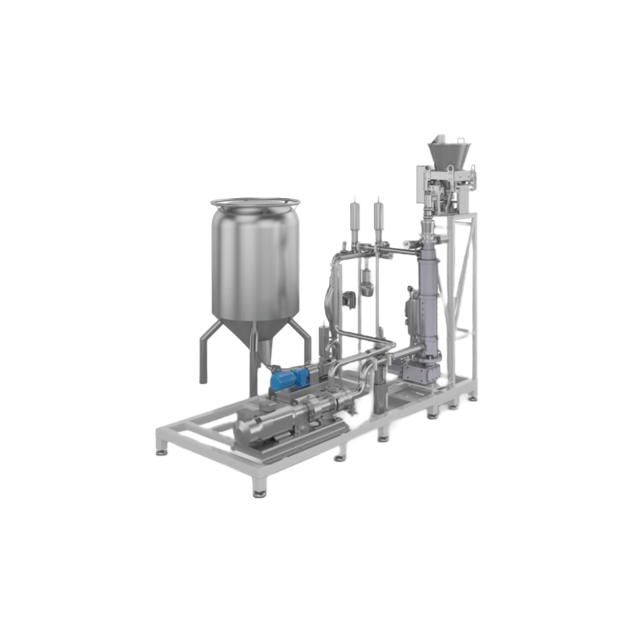

Cosmetic pencil filling system

In the cosmetics industry, the demand for efficient and precise filling of various cosmetic p...

Mascara and lip gloss filling and capping system

In the cosmetic industry, ensuring high precision in filling and capping ...

Mascara and lip gloss filling system for cosmetics

When producing liquid cosmetics like mascara or lip gloss, achieving p...

Lipstick moulding solution for cosmetics manufacturing

In the cosmetics industry, ensuring consistent and high-quality li...

X ray inspection for unstable cosmetic products

In the cosmetics industry, ensuring product safety and quality is paramoun...

Automatic bottle filling and capping solution

For medium to large-scale production, efficient and precise bottle filling a...

Semi-automatic mascara bottle filling and capping

For small production batches of mascara and lip gloss, manufacturers re...

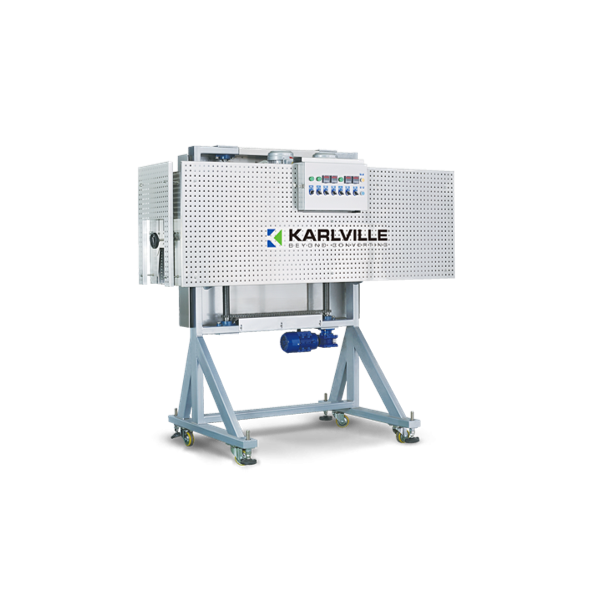

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Automatic blister sealing machine for retail products

Blister packages for retail are usually designed with a paperboard ...

Industrial blister packaging machine for retail products

A blister can be simply defined as a type of packaging that cons...

Automatic lipstick filling machine

Lipsticks, lip balms and lip glosses are very popular cosmetic products that require hig...

Mascara filling machine

For smaller production volumes, a fully automatic filling solution for mascara, eyeliner, lip gloss a...

Automatic mascara filling machine

Do you need to increase your efficiency and production volumes whilst reducing your costs...