Making Lollipops

Find innovative production technology for making lollipops and connect directly with world-leading specialists

Sweets, candies, ice lolly, confection, lollypop, and even popsicles - lollipops, the hard candies attached to a short stick, go by different names. While choosing your lollipop equipment now is very different from the time of its creation, back in 1908, the opportunities to differentiate the product in the market are wider.

Stories about lollipops

Tell us about your production challenge

Importance of homogenization in production

The basic ingredients to make lollipops are popsicles, sugar, gum, corn syrup, and stabilizers. When you combine them, they give the lollipop a texture known as ‘mouthfeel’, which is pleasant to consume. The presence of the sugars and stabilizers makes the lollipop soften in the air, making it edible instead of just melting like ice cubes.

Homogenization is important step in the lollipop production. You need to ensure proper candy mixing to get the concentrated syrup that forms the lollipop. After that, manufacturers use candy depositors, as they offer a variety of molds and accuracy in filling them with homogenized candy.

How to fill lollipops with chewing gum

Adding chewing gums to lollipops to get different flavors is easy to implement into the manufacturing process. When boiling the solution, insert the gum, together with other ingredients, before the solution hardens. This happens when the temperature reaches around 150 °C (310°F) which is referred to as the “hard crack stage”.

The trends in sugar-free lollipops

Sugar-free lollipops are gradually growing in the candy market as more people are looking for healthier alternatives. In 2020, a report forecasted that the global sugar-free confectionery market would to grow at a compound growth rate of 5.1% until 2027.

To produce sugar-free candies, use substitutes like neotame, isomalt, maltitol, and sucralose. Known as sugar alcohols, they are all lower in calories compared to regular sugar. They originate from fruits and vegetables, which means they are natural options. The only possible health concern with them is that, when eaten in large amounts, they can have a laxative effect, causing bloating.

These substitutes are 90% as sweet as sugar so they do not change the flavors of the lollipop. The production process is not any different from that of sugar candies. You also need to cook the sugar substitutes, shape and cool them before packaging.

Processing steps involved in lollipops making

Which lollipops technology do you need?

Vision guided multi-robot system for flowpack candy packaging

In confectionery manufacturing, efficiently picking, arran...

High-speed flow wrapper for candies and gums

In the confectionery industry, packaging small items like candies, gums, and ...

Flow wrapping for bulk confectionery products

Handling small confectionery products coming in bulk can be challenging due ...

Systems for processing confectionery rework

In confectionery production, waste such as sugar dust, start-up and shut-down ...

Cooling tunnel for confectionery extrusion

Efficiently cooling and conditioning extruded confectionery products to room te...

Preforming line for candy rope production

In the confectionery industry, producing consistent candy ropes for downstream f...

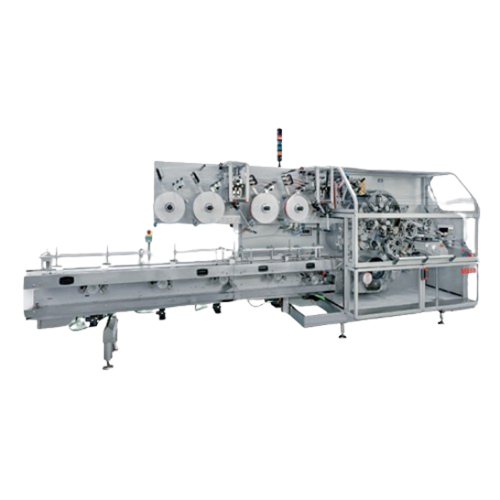

Stickpack wrapper for lollipops

In the confectionery industry, packaging efficiency and distinctive presentation are key to ...

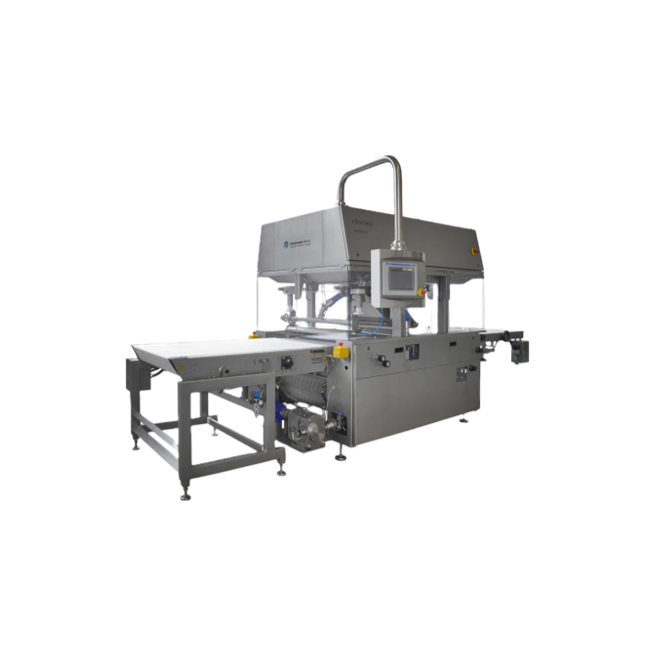

Flow wrapper for lollipops packaging

In high-volume candy production, ensuring lollipops are securely and hygienically pack...

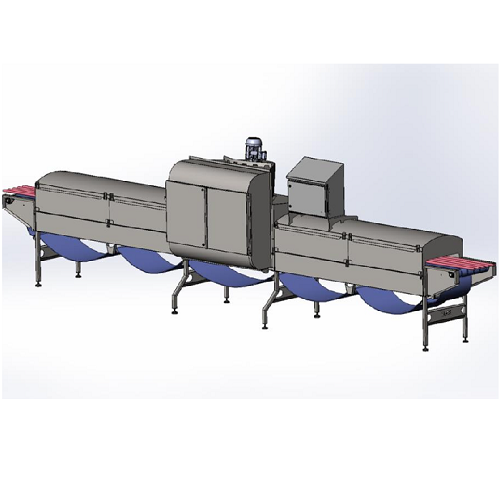

High precision lollipop cooling system

In confectionery production, maintaining the shape and quality of lollipops during t...

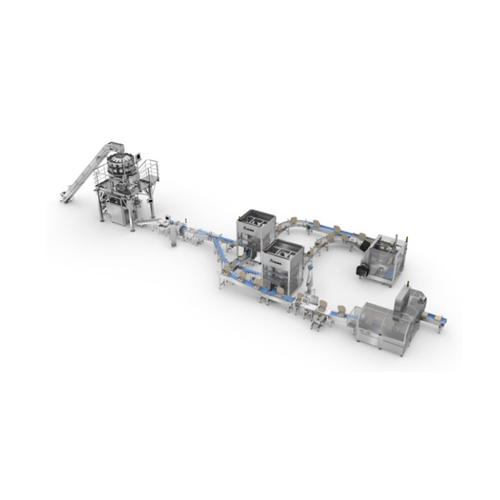

Continuous lollipop forming system

Producing high-quality and visually appealing lollipops requires a system capable of han...

4-sides seal wrapping for lollipops

Ensuring lollipops are securely and attractively wrapped is crucial for both entry-leve...

Bunch wrapper for lollipops

In the lollipop manufacturing industry, achieving consistent and high-quality wrapping for vario...

Versatile confectionery cut and wrap system

In large-scale confectionery production, maintaining consistent sizing, cuttin...

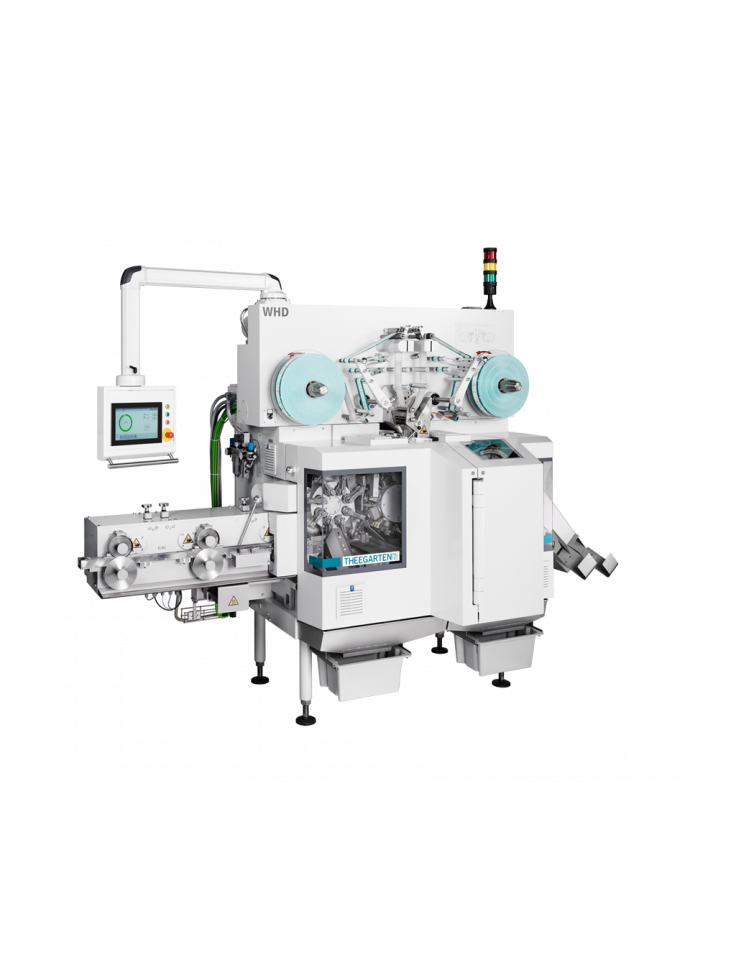

Multi-style candy and chocolate wrapper

Manufacturers dealing with high-speed candy and chocolate production need efficient...

Double twist wrapping solution for candy packaging

When producing preformed candies in large quantities, ensuring consist...

Lollipop forming system for various shapes

In the confectionery industry, creating high-quality lollipops with consistent ...

Automated bagging system for confectionery products

Packaging confectionery products efficiently and consistently calls f...

Longitudinal slitting system for confectionery production

In the confectionery industry, achieving the correct width for...

Licorice cooling tunnel

Licorice and other extruded food products like vegan meats can be tricky to cool in the production pr...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

High-speed cut and wrap double twist machine

Many gums, chewy candies, toffees and caramel products are most suited to ind...

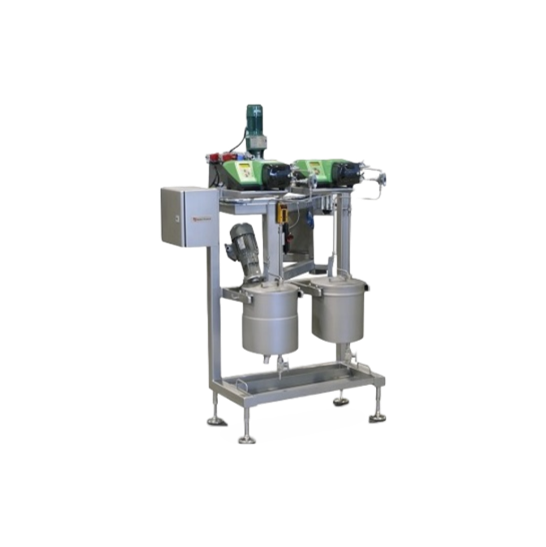

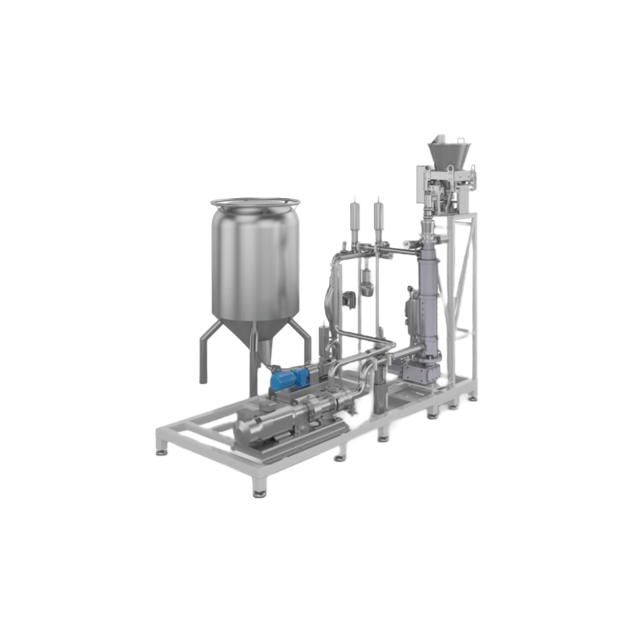

Automatic premixer for hard candy

Feed materials to your confectionery process equipment in a consistent and convenient way...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

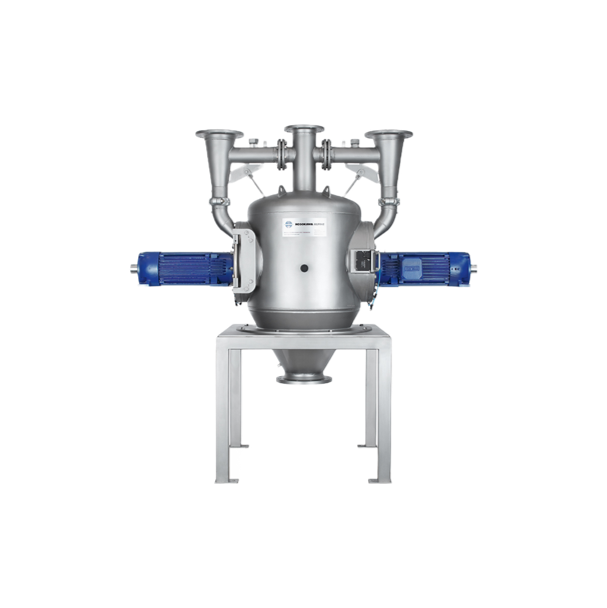

Continuous cooker for hard candy

Prepare your ingredients for hard candy production. This is a continuous dissolving, cookin...

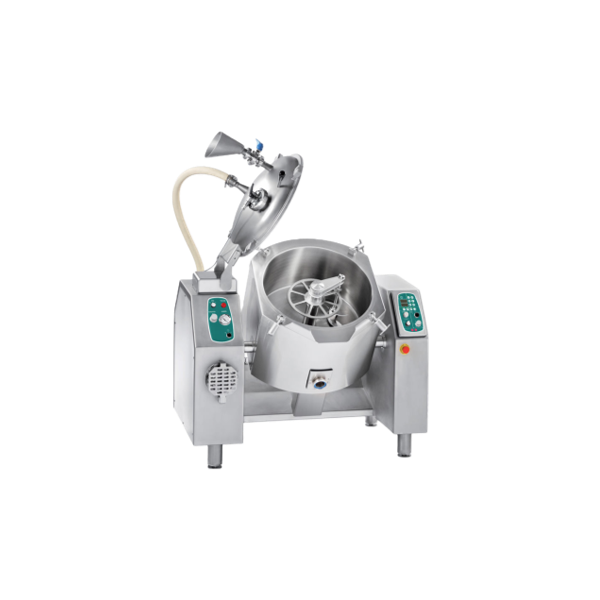

Batch cooker for hard candy

Prepare your ingredients for the production of hard candy. This is a line of universal candy coo...