Making Nitrogen Fertilizer

Find innovative production technology for making nitrogen fertilizer and connect directly with world-leading specialists

Growing populations and intensive farming in the last centuries reduced soil nitrate levels. Aware of the risks to food security, chemists Fritz Haber and Carl Bosch developed a way to industrialize synthetic nitrogen fertilizer production. They created the Haber-Bosch process for ammonia synthesis which is still used today. Manufacturers produce over a hundred million metric tons of nitrogenous fertilizers every year.

Select your nitrogen fertilizer process

Tell us about your production challenge

The principal ingredient in nitrogen fertilizer production is Ammonia

Nitrogen fertilizers (N-fertilizers) are nitrous compounds used to improve crops’ growth, texture, and quality. Nitrogen fertilizer production starts by combining the nitrogen from the air with the hydrogen in a natural gas, usually methane. The resulting mix – Ammonia – is formed in a reactor at high temperature and pressure. Ammonia is sometimes applied directly as fertilizer, but its primary purpose is for manufacturing fertilizer. You can reuse a percentage of it to produce electricity and heat.

After this first step, ammonia is used to make nitric acid, urea, and ammonium nitrate for feedstock. Mix it with other ingredients to produce other fertilizers such as NPK’s (nitrogen, phosphorus, potassium) and UAN (urea ammonium nitrate). The industry also uses sewage, manure, and agriculture by-products to make N-fertilizers.

Develop the nitrogenous process into dry or liquid fertilizers

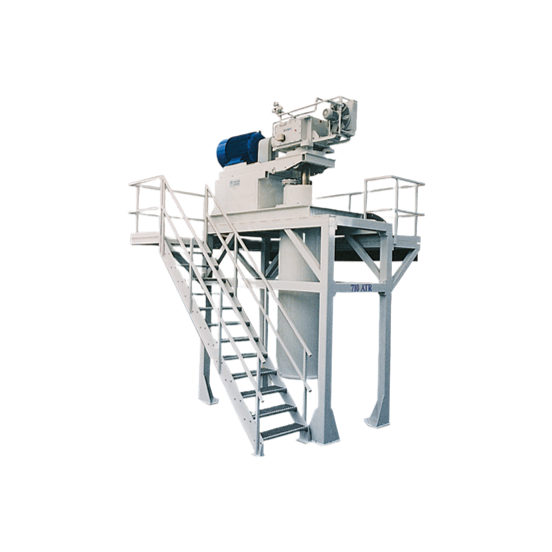

N-fertilizers are typically produced in either dry or liquid forms. Dry fertilizers are made with pellet mills or crumblers, also known as granular fertilizers. They are slow-releasers and may be made from an organic or natural source like cottonseed meal powdered fertilizer. Dry fertilizer obtained from chemical reactions, such as urea, cannot be used in organic farming.

On the other hand, liquid fertilizers provide nutrients in a faster way. Most of them are diluted in water and are spread more evenly. They are transported and stored in special tanks to avoid leakage and environmental damage.

Regulations control nitrates concentration to prevent environmental damage

N-fertilizers have many benefits and a considerable risk of causing substantial ecological damage. Nitrogen is about 300 times more polluting than carbon dioxide. If applied in excess, it causes land degradation, air pollution, and contamination of groundwater sources.

Many jurisdictions, including Europe, the USA, China, and Australia, enacted laws to regulate N-fertilizers in farming and prevent nitrates concentration and environmental damage. A significant challenge in the sector is to produce greener nitrogen fertilizers and apply them more efficiently and sustainably.

Processing steps involved in nitrogen fertilizer making

Which nitrogen fertilizer technology do you need?

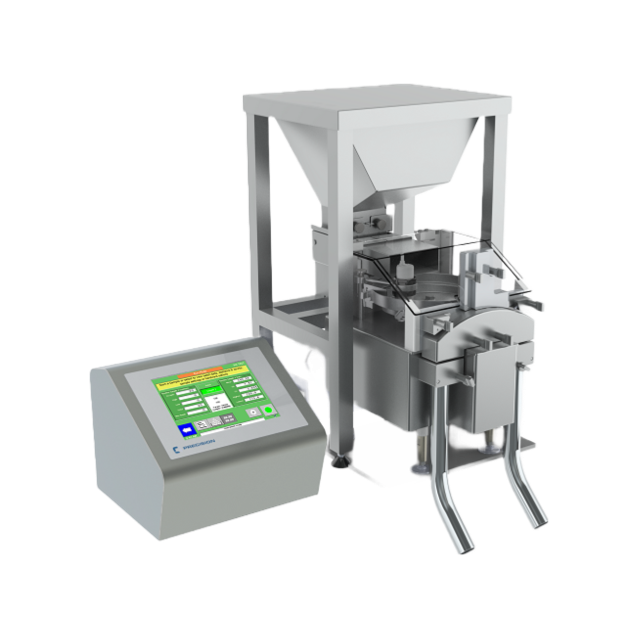

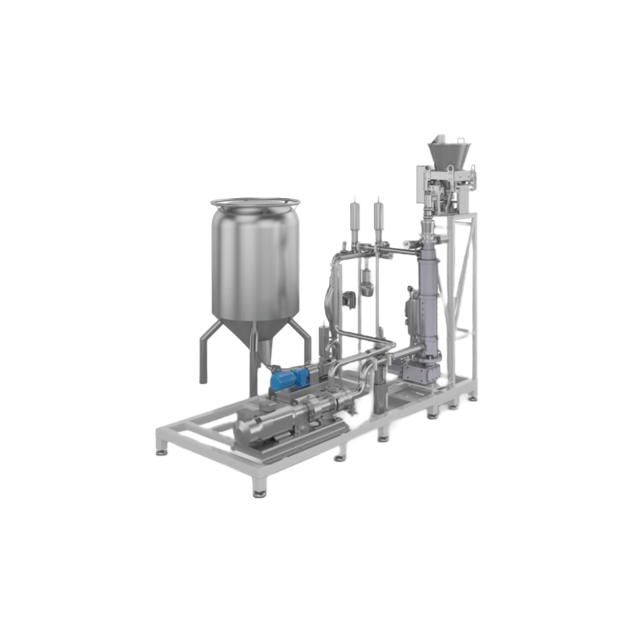

Loss-in-weight feeder for poor flowing bulk solids

When working with extremely poorly flowing bulk solids in industries s...

Bead mill for crop protection

To optimize qualities like particle size, distribution, solubility, and miscibility of active ...

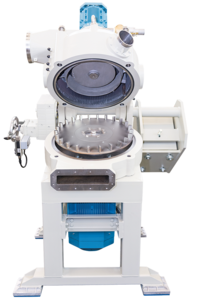

Classifier mill for recovered carbon black

Recovered Carbon Black (rCB) can be recycled back to the tire production chain ...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Automatic palletizer machine for bags and boxes

The effective placement and positioning of bags and boxes can be a challen...

Packaging machine for sealed plastic bags from 250 g to 10 kg

Sealing small quantities of solids or liquids into plastic...

Big bag discharge system

Dust emissions, product loss and product contamination are the main risks when discharging products ...

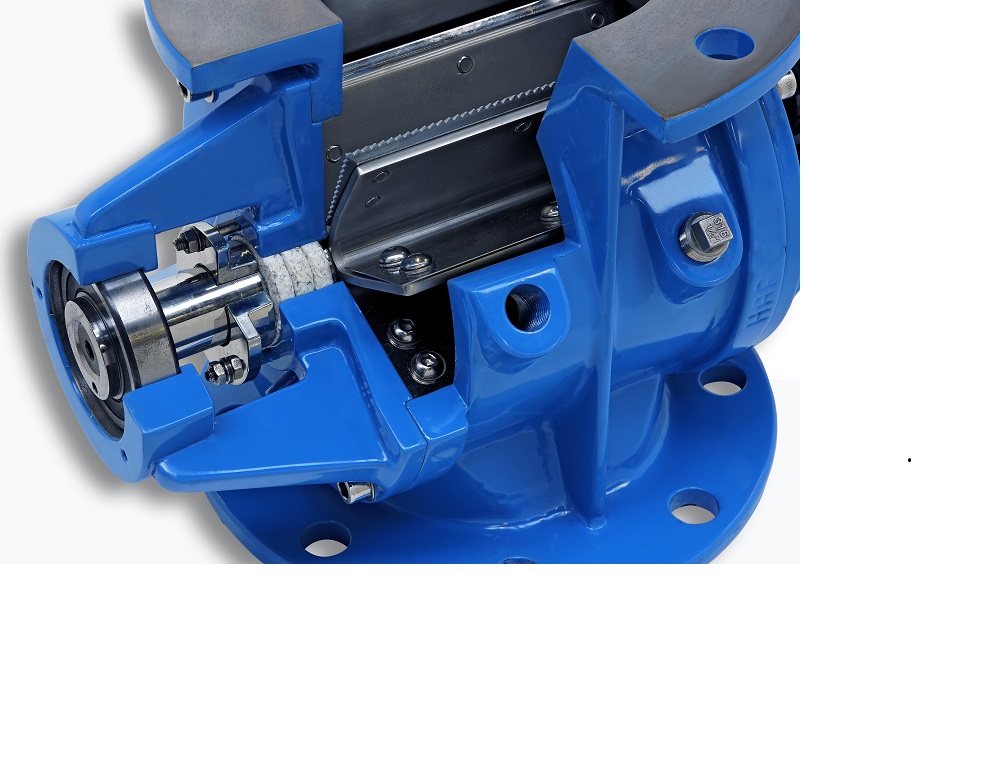

Light duty rotary dust valve

In some light industrial applications there is limited pressure differential for valve operation.

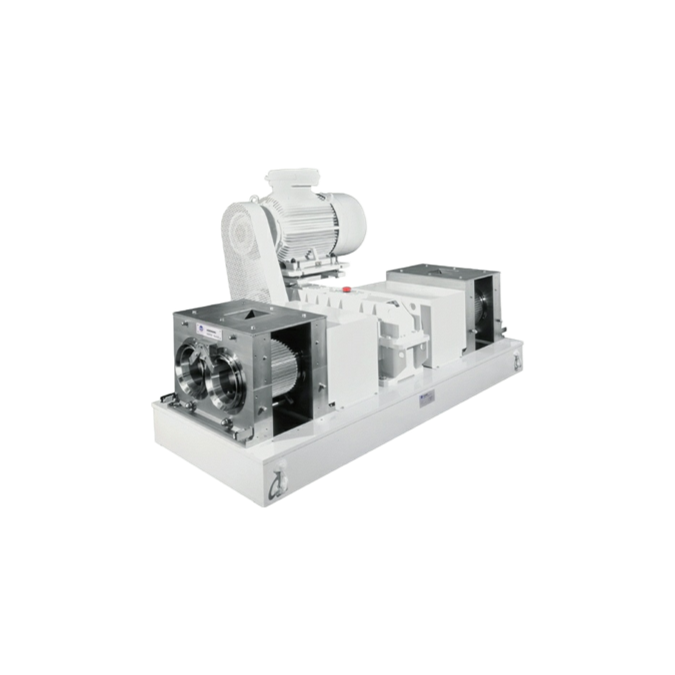

Heavy duty rotary valve

Handling powdered and granulated materials in pneumatic conveying systems requires consistent, safe v...

Special duty horizontal metering valve

Occasionally, there is no suitable standard valve available for a particular conveyi...

Dual channel plug diverter valve

Short switching times are often required when diverting or combining powder or granular sol...

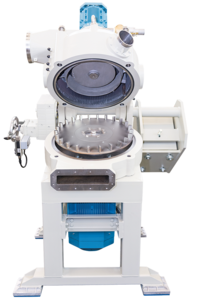

In-process weighing system for mills

When you need a throughput weigher for modern flour/grain milling applications, the we...

Robot palletizer

Palletize up to 1,800 large industrial bags per hour at a multi-pick-up configuration.

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....