Equipment And Machinery For Making Pellet Snacks

Find innovative production technology for making pellet snacks and connect directly with world-leading specialists

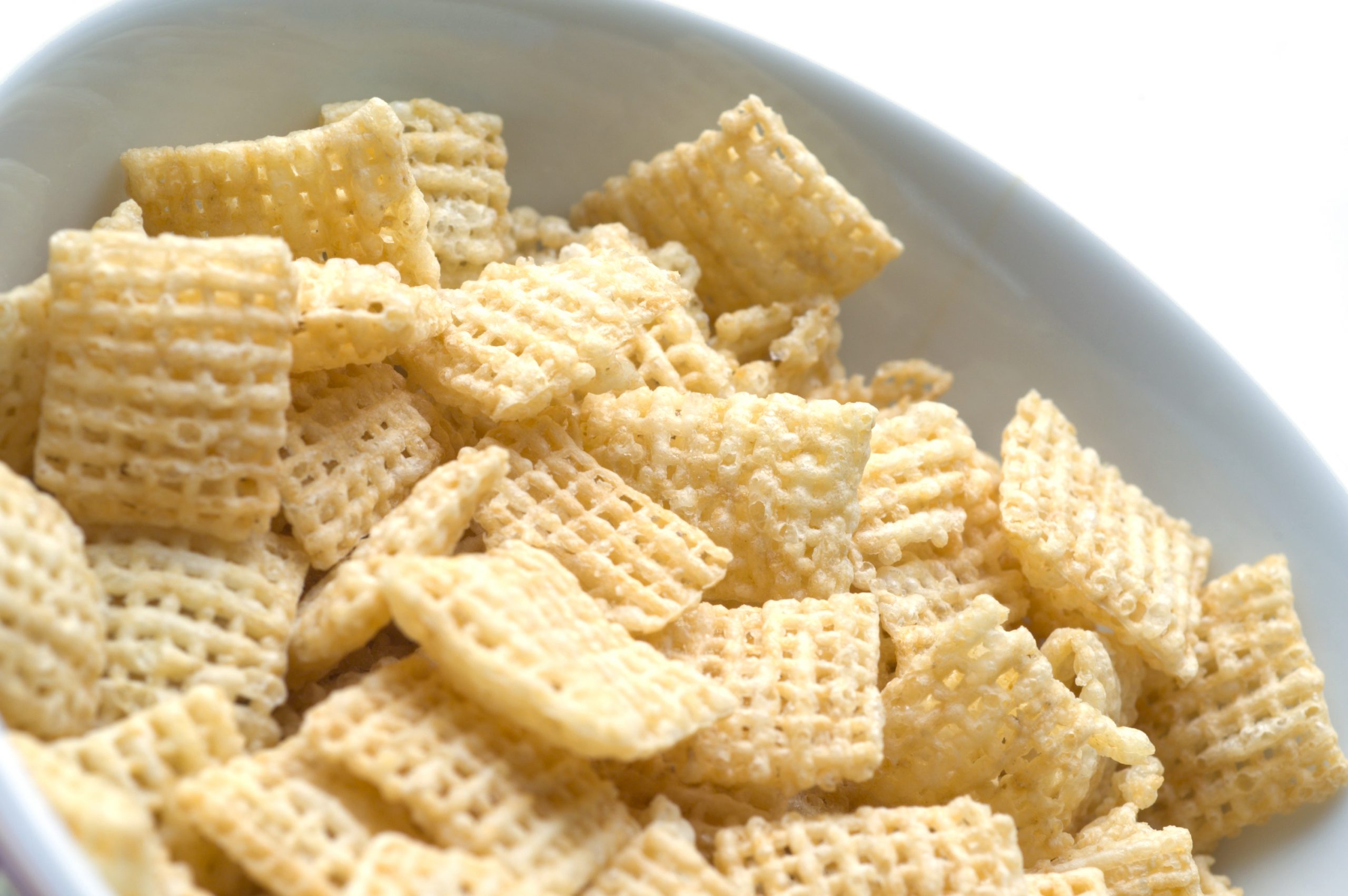

Pellet snacks, or snack pellets, are intermediate products which you can further process and develop into snack products for consumption. Pellet snacks production involves mixing, extrusion, frying, and packing. Since these are intermediate products, final product customization on the production line will depend on your customer’s desired product and flavor profile.

Stories about pellet snacks

Select your pellet snacks process

Tell us about your production challenge

A multitude of processes and end products

Common base ingredients for snack pellets include raw materials such as cereals, potatoes, corn, wheat, and grains. In addition, you can add functional ingredients to increase the nutritive value of your pellet snacks, such as high fiber and high protein fortificants. With these, you can mix and match the base and functional ingredients to achieve the pellet snack profile you or your customer desires. Furthermore, the pellet snack can be processed into a 2d or 3d final product by the manufacturer.

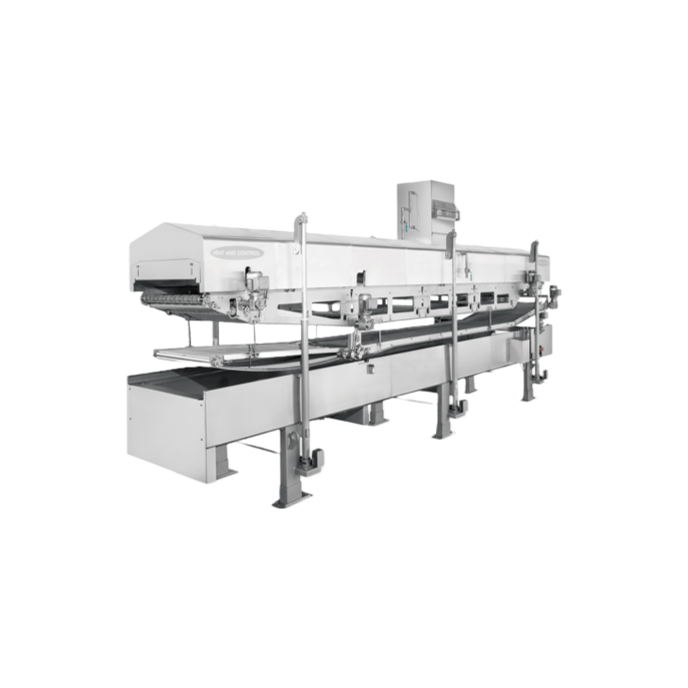

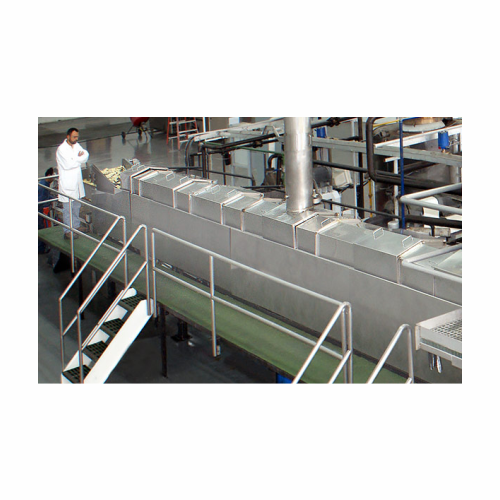

The shelf-life of your pellet snack relies heavily on your frying process and its parameters due to its effect on your product moisture and rancidity. Selecting the correct frying technology would help you optimize the snack pellet production process while maximizing your product shelf-life. Continuous conveyor fryers are the best choice snack making equipment for continuous systems.

In addition to the technology, how hot and how long you fry contribute to your snack’s final profile. The correct combination of these coupled with your raw ingredients and snack shape determines how your snack pellets will turn out after processing.

Experimental encounters in extrusion

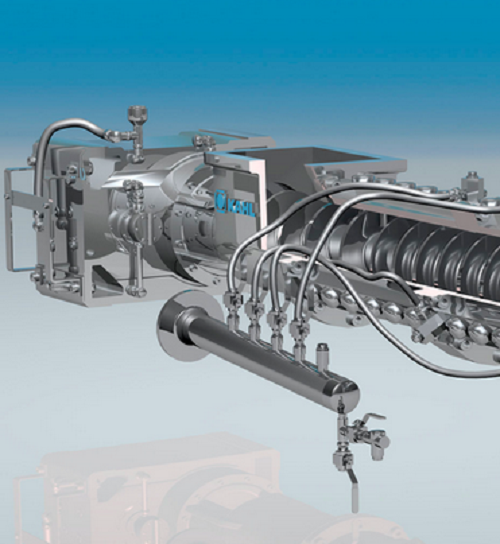

Extrusion is the core process of pellet snack manufacturing. How you extrude your raw material determines how the final snack pellet behaves. Machine parameters such as pressure, temperature, and die-cut allow you to design your product based on the customer’s needs. The extruder step is critical to making pellet snacks successfully.

The use of lipid in your extrudate greatly and indirectly affects the final quality of your snack pellet. The amount of moisture in your intermediate product factors into your final snack pellet texture. Using the correct oil amount during snack pellet production will help avoid defects from improper moisture content during your snack pellet production. A study showed that a range of 4% to 6% oil in your extrudate results to desirable snack pellet properties. Quality issues such as lack of crispiness, shape deformation, and cutting imperfections can then be avoided if you use the correct amount of oil.

Trimming your snacks’ fats

De-fatting your pellet snacks increases its appeal as a healthy snack alternative. One of the most common methods to remove oil is by using de-fatting belts and air knives. The process is essential to ensure the snack crispiness is maintained and shelf-life is prolonged by preventing rancidity.

De-fatting belts allow excess oil from the surface of the pellets to drip through the conveyor. Vibrations applied by the conveyor further hasten the removal of oil. You can then collect and re-use the dripped oil for succeeding snack pellet frying. Air knives can further remove the oil through application of the right velocity and volume of air pressure, with the maximum as high as 40,000 ft/min, to the snack pellets after frying.

Processing steps involved in pellet snacks making

Which pellet snacks technology do you need?

High pressure extruder for expanded snacks

Producing expanded snack foods like curls, rings, and balls requires a precise ...

Single-screw high shear extruder

In snack production, achieving consistent shape, texture, and density requires precise cont...

Pellet snack production line for industrial use

Expanding the market for pellet snacks involves producing various flavors,...

Gear pelletizer for stable cylindrical pellets

In industrial processes where transformation of powders or particles into u...

Single-screw cooking extruder for snack production

Producing high-quality savoury and sweet snacks like curls, balls, and...

Cooling drum for seasoned extrudates

When producing extruded snacks, maintaining the right texture and quality post-seasoni...

Industrial drum dryer for extruded snacks

In snack production, achieving the right residual moisture level in extruded pro...

Seasoning drum for extruded snack products

In industrial snack production, consistent and even seasoning application on ex...

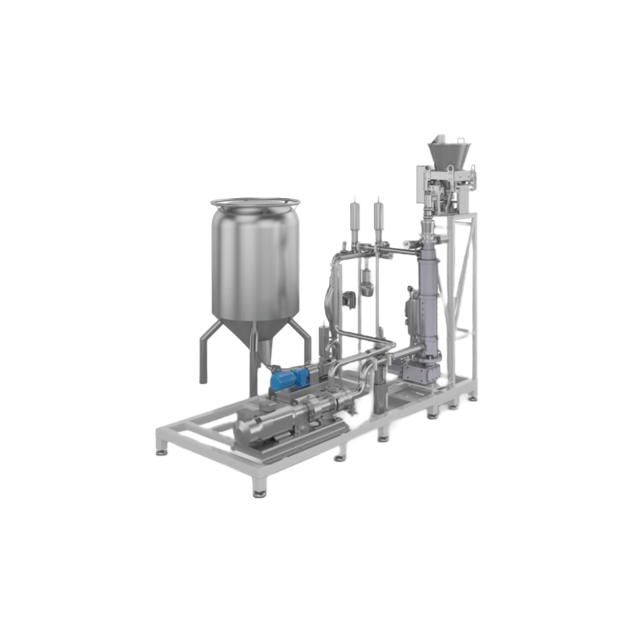

Seasoning mixing system for extruded snacks

When producing extruded snacks, achieving uniform seasoning distribution can b...

Snack food fryer with consistent thermal fluid heating

In large-scale snack food production, achieving consistent color a...

Conveyor systems for snack production

In snack production, efficient and reliable transport of raw materials and products i...

Universal fryer system for snack foods

In snack food production, the ability to customize recipes on-demand and ensure cons...

Industrial pellet fryer for high quality snack production

In snack production facilities, achieving uniform and controll...

Industrial snack food fryer

In the snack food production industry, maintaining precise temperature control and consistent fr...

Pellet snack fryer

In the production of pellet snacks, managing oil use and achieving uniform cooking are critical challenges...

Oil curtain fryer for snack production

High-speed snack production lines often face the challenge of maintaining oil qualit...

Flexible fryer for various snack products

When producing a diverse range of snack foods like potato chips, cheese puffs, o...

Ambient air cooling system for food products

In food production, it’s crucial to rapidly cool products to stop cooki...

Rotary drum sifter for pellets and chunks

When processing pet food, feed, or similar bulk materials, achieving precise siz...

Vertical case packer for reusable and Rsc cases

In facilities where efficient secondary packaging is crucial, managing dif...

Packaging conveyor for efficient bag handling

In high-volume packaging environments like food processing facilities, manag...

Modular rotary oven for snack food processing

Processing snack foods like popcorn, roasted nuts, and coated nuts often req...

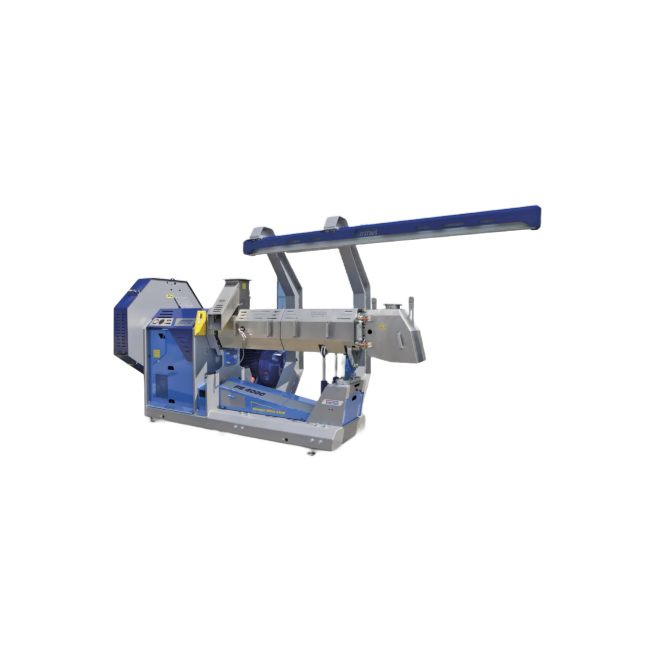

Hot cutter for processing extrudate into pellets

In manufacturing environments where extrudates need to be processed into ...

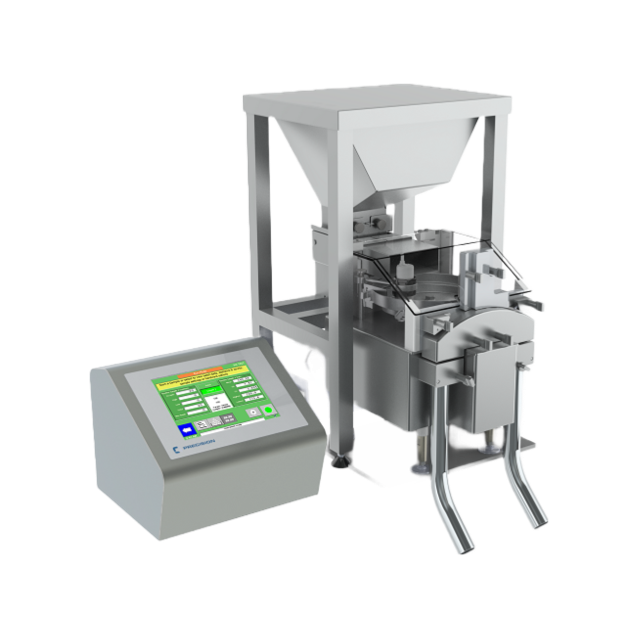

Batch mixers for raw material preparation in extrusion processes

In food production industries, particularly those invol...

Food product extruder for low to high capacity production

In the food manufacturing industry, efficient production and c...

Pellet snacks frying line

Pellet-style snacks represent a broad food sector category. They are consumed worldwide and vary a...

Flavouring system for healthy rice cakes and snacks

Being active on the market for healthy popped snacks asks for a flexi...

Confectionery bags case packer for large scale

Mass production lines need faster and more efficient package processing to ...

Puffed snack making machine

In the snack food industry, most products are often fried or extruded with a cooker, before bein...

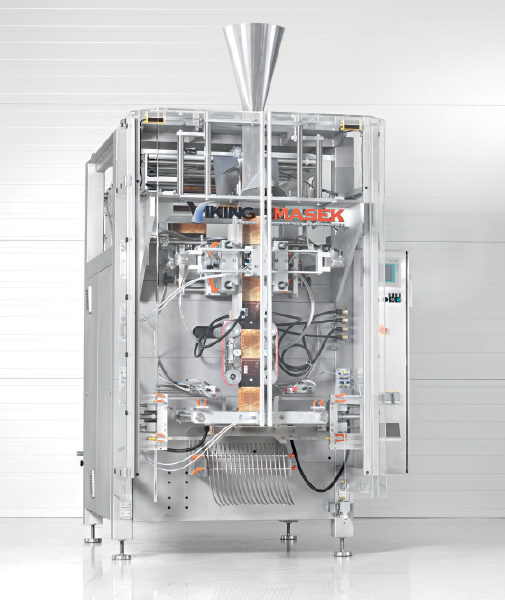

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

Extruder with annular gap expander

Products can be extruded with various shapes and characteristics by controlling the nozz...

Laboratory extruder

Products can be extruded with a variety of shapes and characteristics by controlling the nozzle geometry ...