Making Polymers

Find innovative production technology for making polymers and connect directly with world-leading specialists

All plastics are polymers, but not all polymers are plastics. Polymer production is a multi-step process that transforms raw materials into products that we use in our day-to-day life with the help of polymer process equipment such as extruders, calenders and injection molding machines.

Select your polymers process

Tell us about your production challenge

What are polymers?

Polymers are natural or synthetic substances composed of macromolecules that are multiples of simpler chemical units called monomers. Natural polymers are found in living organisms, including proteins, cellulose, nucleic acids and starches. On the other hand, synthetic polymers are derived from petroleum oil, with examples of nylon, polyester, and Teflon.

Addition polymerization vs condensation polymerization

There are two types of polymerization: addition and condensation polymerization. In the former, a polymer is formed simply by linking monomers together without co-generating by-products. The addition polymerization has three steps: initiation, chain propagation and termination of the chain. During addition polymerization, the monomers rearrange and form a new structure without losing atoms or molecules. It results in homo-chain polymers such as polyethylene, polystyrene and methacrylates.

During the condensation polymerization, monomers are joined by releasing other small molecules as a byproduct, for example, water or methanol, resulting in hetero-chain polymers. For instance, cellulose, starch, nylon and polyester are the results of this process. These polymers tend to be more biodegradable due to weaker bonds.

Manufacturing processes and polymer process equipment

Extrusion, calendaring…

Transforming polymers into practical products starts by adding additives according to the desired specifications. Polymeric materials in the form of powder, granules or melts are transformed into end products by extrusion. It is a process in which plasticized material is forced through an orifice and cooled once it achieves the favored shape.

Polymer process equipment includes a variety of extruders, such as ram extruders for short product lengths, gear pump extruders for pre-plasticized and low-viscosity materials and a single screw extruder which produces the majority of extruded products, especially those with a constant profile such as window frames.

Another widely used method is calendaring – processing molten polymers, mostly rubber and thermoplastic, by squeezing them between a pair of heated counter-rotating rolls in a machine called calendar, which can easily be set up to produce preferred thickness and size. This process is used to manufacture floor tiles, shower curtains, signs, and displays.

…and injection molding

Injection molding is the leading process for producing complex shapes, for example, toys, some musical instruments, or automotive parts. The process in the injection molding machine consists of four phases: plasticization, which transforms thermoplastic powder or granules into a homogeneous melt state, injection of melt from the plasticization unit to all parts of the mold cavity, setting of the melt in the mold cavity and ejection of the finished product from the mold.

Technological Innovations: the versatility and future of polymers

Polymers can be used for various and unique products, some of them seemingly aiming to change our lives in the future. For instance, scientists from Defense Advanced Research Projects Agency developed a polymer foam that can be injected into an abdominal cavity and later easily removed to stop bleeding. Harvard University scientists found a way to inject polymers through needles, heal damaged tissue, and use polymers in robotics to add flexibility. Polymers can further be used to create artificial skin, ideal for prosthetics. Moreover, polymers might be an answer to cancer, as Duke University scientists tested a thermally responsive radioactive peptide polymer that is effective at controlling tumors. Other innovative applications are scratch repair, lotions against intense heat, and creating transparent soil.

Sustainable polymers as a solution

Sustainable polymers are materials that cater to consumers’ needs without damaging the environment. Namely, renewable sources, such as carbon dioxide, terpenes, vegetable oils and carbohydrates can be used to produce a variety of polymer end-products. Sustainable polymers can be made by fermenting the plant material to produce monomers, such as plant-derived sugar to lactic acid.

Another alternative is extracting chemicals from the plant like soybean oil or natural rubber. Finally, bioengineering and microbial pathways can convert plant molecules into monomers. Renewable polymers found their use in packaging, automotive parts and 3D printing. Sthereochemists strive to find a way to manufacture sustainable polymers while they keep the mechanical and physical properties of traditional plastics.

Economic and renewable – using CO2 to make polymers

The ability to use, and therefore reduce, CO2 emissions and convert them into usable products is the perfect example of renewability. Having significantly lower greenhouse gas emissions, CO2-based polymers are a striking sustainable alternative due to the source material being abundant, renewable, and inexpensive. As a very thermodynamically stable molecule, CO2 requires a significant amount of energy to be activated which is achieved with a specially-designed catalyst that reduces the energy barrier.

So far, there are two different approaches to introducing CO2 onto polymers. One is having CO2 participating directly in the polymerization process as a comonomer. The second approach uses CO2 for building blocks that are yet to undergo the polymerization process. This method could almost replace fossil raw materials as nearly all chemical products that use them can be produced from CO2.

Processing steps involved in polymers making

Which polymers technology do you need?

Laboratory homogenizer for nanoemulsions and dispersions

In laboratory settings, precise cell lysis, particle size reduct...

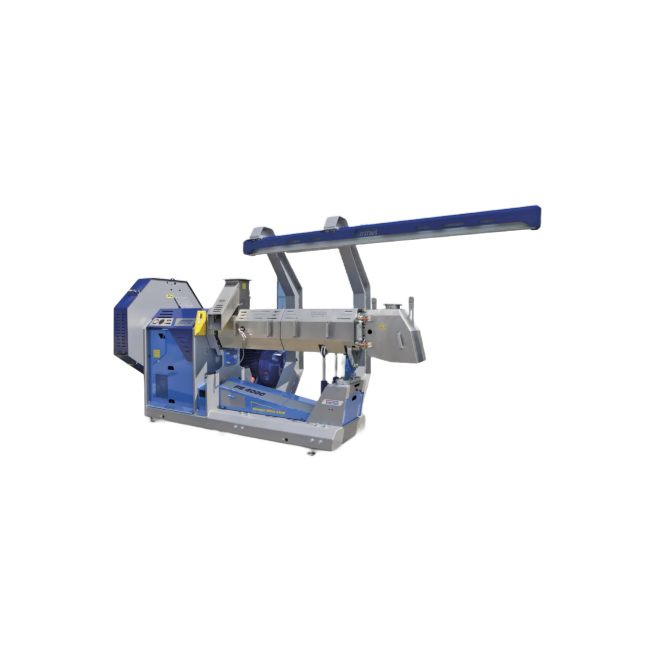

Beside-the-press granulators for injection molding

In injection molding or extrusion operations, there is often a need to...

Central granulators for high-volume plastics recycling

In industrial recycling processes, handling large volumes of plast...

Heavy duty granulator for high-capacity size reduction

In high-capacity industrial processes, managing large volumes of m...

Thermoforming granulators for efficient material processing

In manufacturing environments, managing the recycling and re...

High efficiency central chiller for industrial cooling

In industries requiring precise temperature control, excessive ene...

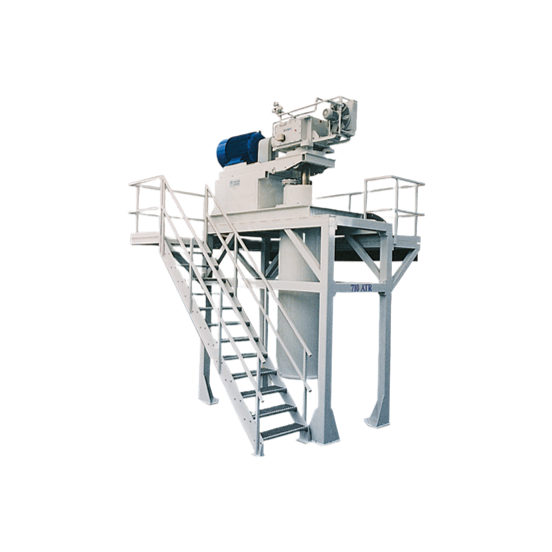

Gravimetric batch blender for precise material handling

When dealing with regrind materials or those difficult to meter h...

3.5 Hp air-cooled chiller for industrial cooling

Effective cooling solutions are key to prevent overheating, maintain prod...

Positive/negative pressure temperature control unit for cooling circuits

In process cooling systems, leaks in the cooli...

Central chiller for consistent process cooling

Manufacturing and industrial processes often require reliable cooling syste...

Compact water temperature control unit

When managing production processes requiring precise temperature control in confined...

Water temperature control unit for production applications

In various production environments, maintaining precise and c...

Stainless steel drying hoppers for plastic processing

Effective drying of plastic resins is crucial for producing high-qu...

Outdoor central chiller for process cooling

In industrial settings with limited indoor space, efficient outdoor cooling sy...

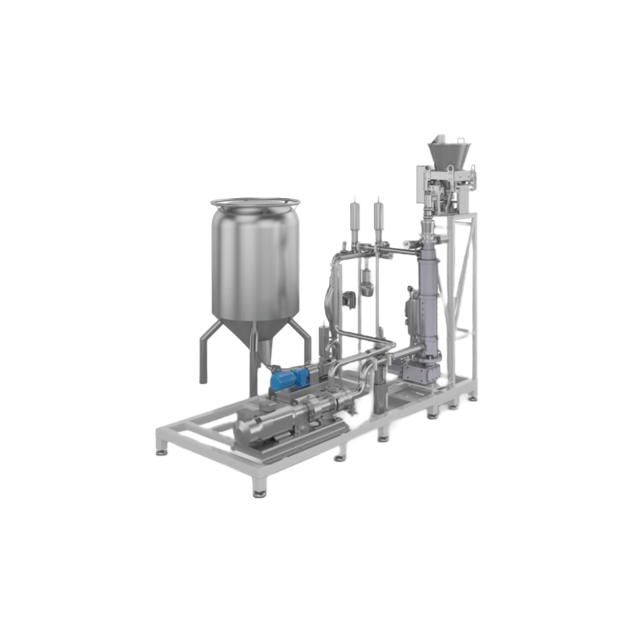

Continuous loss-in-weight blender for extrusion applications

In extrusion processes, ensuring a consistent and homogeneo...

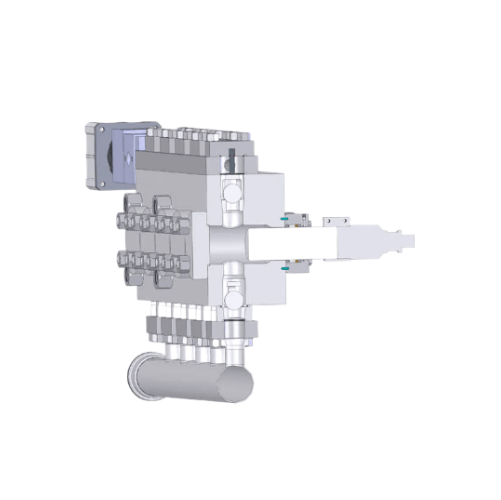

Volumetric additive feeders for injection and extrusion processes

In injection molding and extrusion processes, achievi...

Gravimetric batch blender for injection molding and extrusion

In plastics manufacturing, achieving precise control over ...

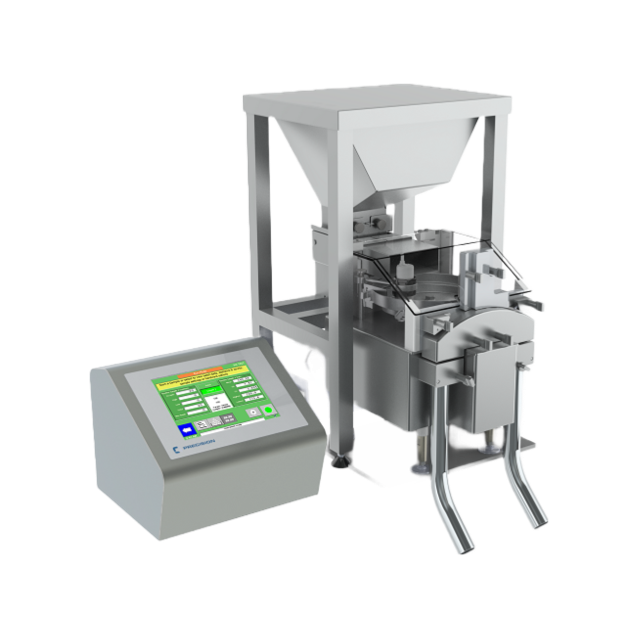

Digital doser system for plastics additive feeding

When working with plastics in injection molding, blow molding, or extr...

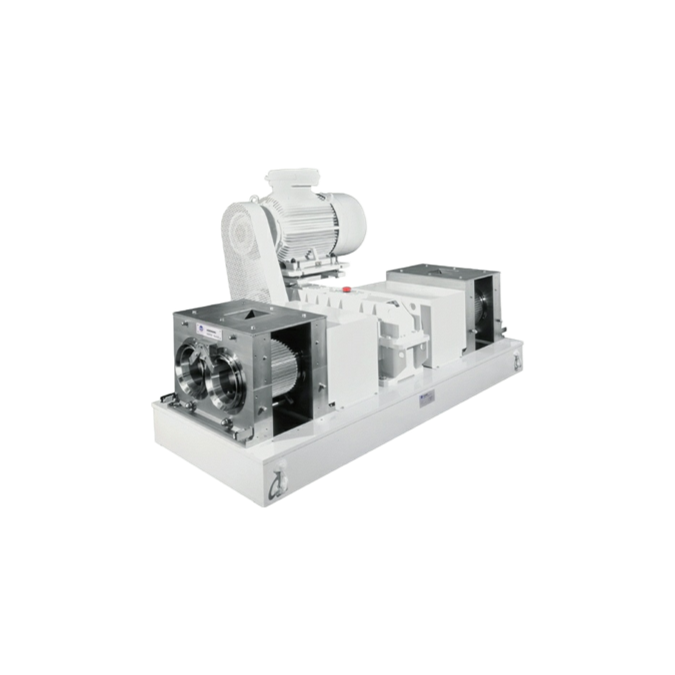

Extrusion control units for high precision manufacturing

Ensuring the accuracy of extruder output and controlling weight ...

Hot air dryers for non-hygroscopic material

In manufacturing processes, drying non-hygroscopic materials efficiently can b...

50l jacketed glass reactor for synthetic reactions

In laboratory settings where precise thermal control and vacuum condit...

50l stainless steel dual-jacketed reactor for chemical processes

Managing temperature-sensitive reactions in the chemica...

10l glass reactor system for synthetic reactions

In chemical synthesis, precise temperature control and efficient material...

150l jacketed glass reactor for chemical synthesis

When conducting chemical synthesis involving controlled temperature an...

High pressure homogenization for polymer nanodispersions

Managing the production of materials like latex and polymers oft...

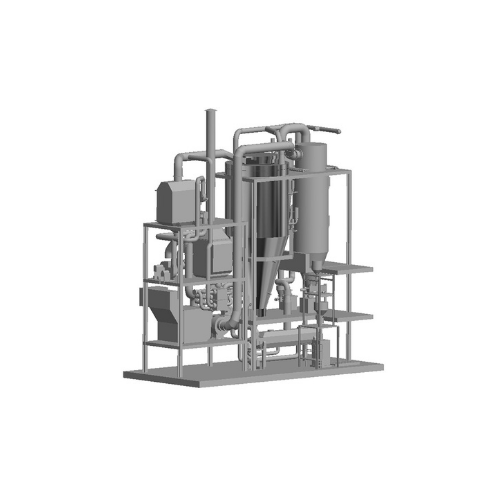

Spray dryers for ceramics and pharma products

When producing high-quality powders for advanced ceramics, polymers, catalys...

Gravimetric loading sifter for dust and streamer removal

In industrial environments where precise separation of dust part...

Spray drying system for heat sensitive products

In industries like food and chemicals, transforming liquid solutions into ...

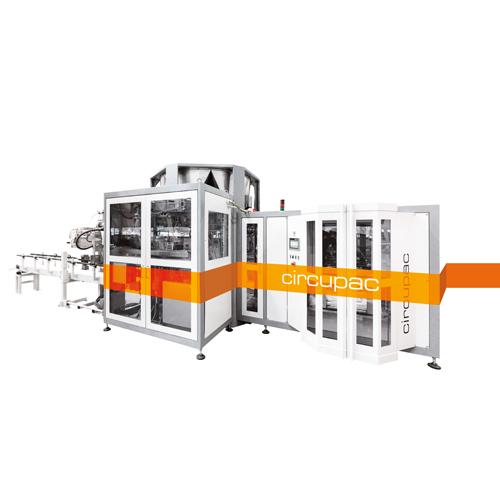

Automatic palletizer machine for bags and boxes

The effective placement and positioning of bags and boxes can be a challen...

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Form fill seal bagging machine

If you are in industries such as petrochemicals, fertilizers, animal feed, food, etc, you mus...

Vertical form fill seal machine

There is an increasing demand for a range of different package sizes of the same product. If...

Robot palletizing system

If you are a relatively large-scale producer, packing and transporting large quantities of products ...

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

High pressure air powered laboratory homogenizer

Offering lab-scale to small pharmaceutical production scale output for in...

Laboratory scale active freeze dryer

The laboratory-scale active freeze-drying is used for dehydrating high-value products ...

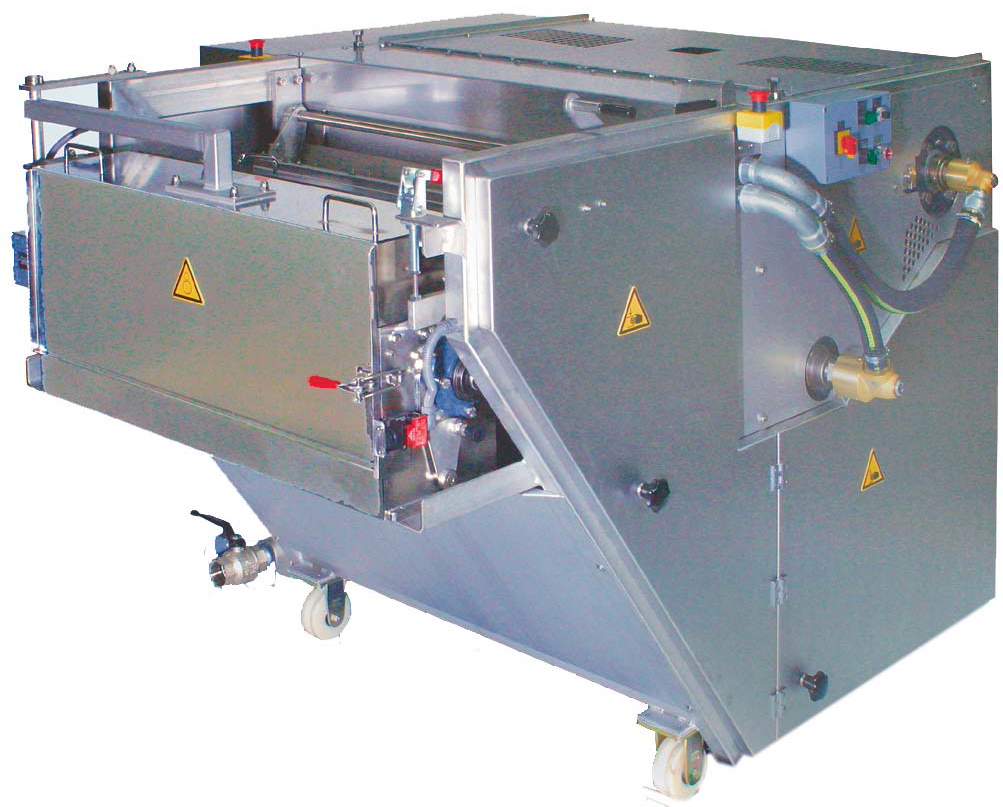

Drum cooler for laboratory hot melt processes

Do you need to cool molten masses to solid, thin film or flakes in an R&...

Drum cooler for hot melt processes

Medium-scale production of extruded hot melt masses benefits from reliable, efficient co...

High capacity drum cooler for hot melt extrusion

Large scale cooling and extrusion of hot melt products on a continuous ba...

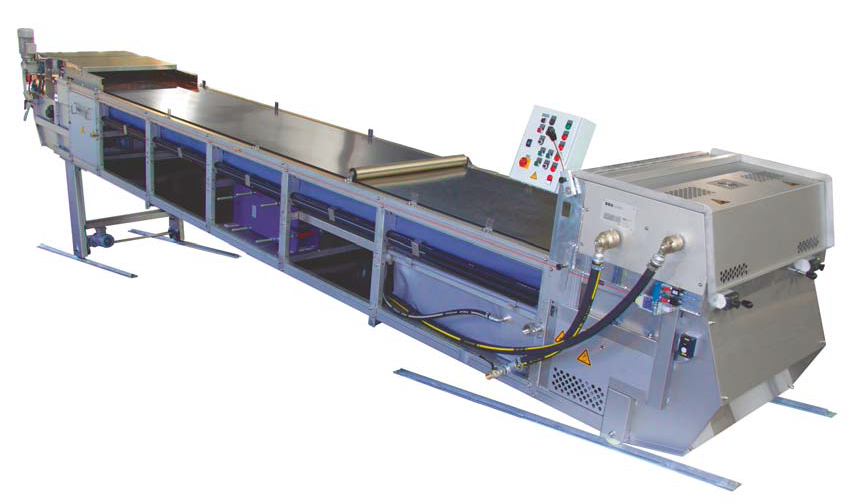

Steel belt cooler for hot melt extrusion

For producing high volumes of extruded hot melt product a flexible, high capacity ...

Laboratory GMP cooler for hot melt extrusion

Pharmaceutical R&D and laboratory extrusion of viscous hot melt masses re...

GMP cooler for hot melt extrusion

Pharmaceutical production of extruded hot melt masses requires a GMP designed, FDA approv...

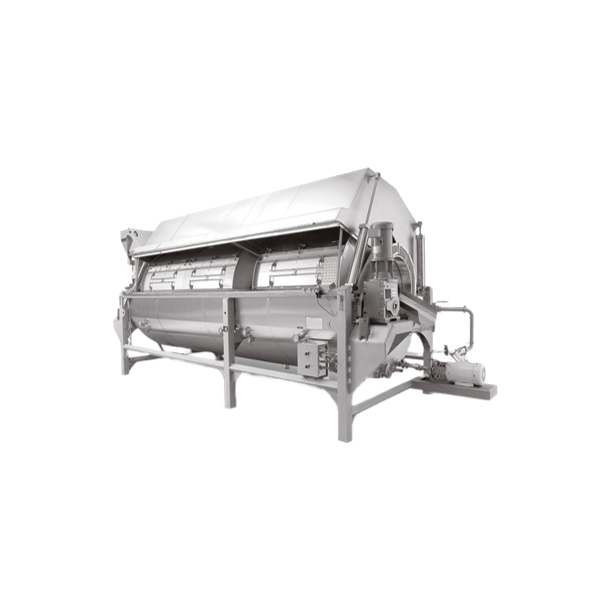

Tumble dryer for granulated plastics

Vacuum drying at high temperatures is important in the production of granulated plasti...

In-process weighing system for mills

When you need a throughput weigher for modern flour/grain milling applications, the we...

Deduster for plastic granules

Industries that use plastic granules see better product quality and decreased equipment wear a...

Robot palletizer

Palletize up to 1,800 large industrial bags per hour at a multi-pick-up configuration.

Versatile open-mouth bagger

If you want highly precise bagger for bagging multiple bag materials, here you go. This versatil...

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

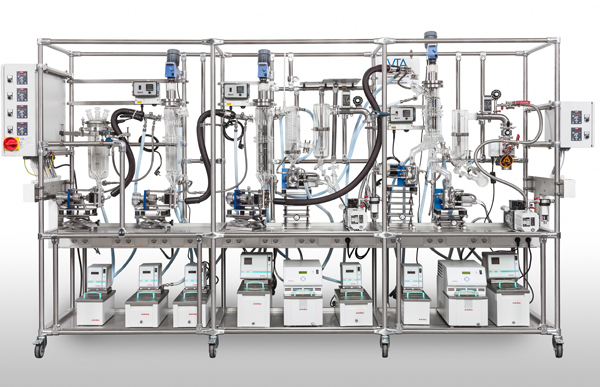

Pilot multi-stage distiller

If generating an scalable data and bring in results with small sample quantities of high-boiling...

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Thin film dryers

Dry dissolved or slurried crystallizing or amorphous products to a pourable powder.

Short path evaporators

With short path distillation, a substantial decrease of boiling temperature is obtained by reducing th...

Pipe bend to reduce fines

A specialized pipe elbow for pneumatic conveying systems that virtually eliminates the friction an...

Laboratory granule dedusting analyzer

High quality clean bulk materials are used in many industries including plastics, foo...

Small scale deduster for plastic granules

Industries that use bulk plastics see better product quality and decreased equip...

Deduster for injection moulding

High quality injection molded plastic parts require clean bulk resins free of dust and strea...