Adhesives Manufacturing Equipment

Find innovative adhesives equipment and connect directly with world-leading technology suppliers

Adhesives are grouped according to their form, origin - natural or synthetic - and their material joining method. You can make natural adhesives from plant and animal sources such as bones, hide and skin, agar, dextrin. Manufacturers count with adhesive making equipment to produce synthetic adhesives from organic compounds. They include epoxy adhesives, cyanoacrylates (or super glue), acrylic adhesives and so on.

Stories about adhesives

Select your adhesives process

What are you making?

Tell us about your production challenge

Reactiveness: when adhesives need special conditions for bonding

Further classification of adhesives involves their method of reaction. This implies that they may or may not need chemical reactions to harden. Reactive adhesives bond in the presence of a reactive catalyst like heat, moisture and absence of oxygen to solidify. Non-reactive adhesives harden by drying. Acrylic adhesive is reactive and you can produce it by the reaction of acrylic and methacrylic acids in the presence of a special activator, which initiates bonding. An acrylic reactor for helps get a better yield. Hot glue making can happen with batch processing, using a kettle mixer, for instance, or continuous extrusion. Adhesive making equipment automates large scale production.

Industrial production: how the adhesive making equipment design helps make quality adhesive

Solvent-based adhesives are suitable for different kinds of substrate, which explains their vast application in the manufacturing industry. You can use it in the medical industry, the packaging industry and for automobiles. Solvent- and water-based adhesives are both beneficial to manufacturers depending on their application. The former dries very quickly because they are made with hydrocarbon solvent such as acetone and toluene.

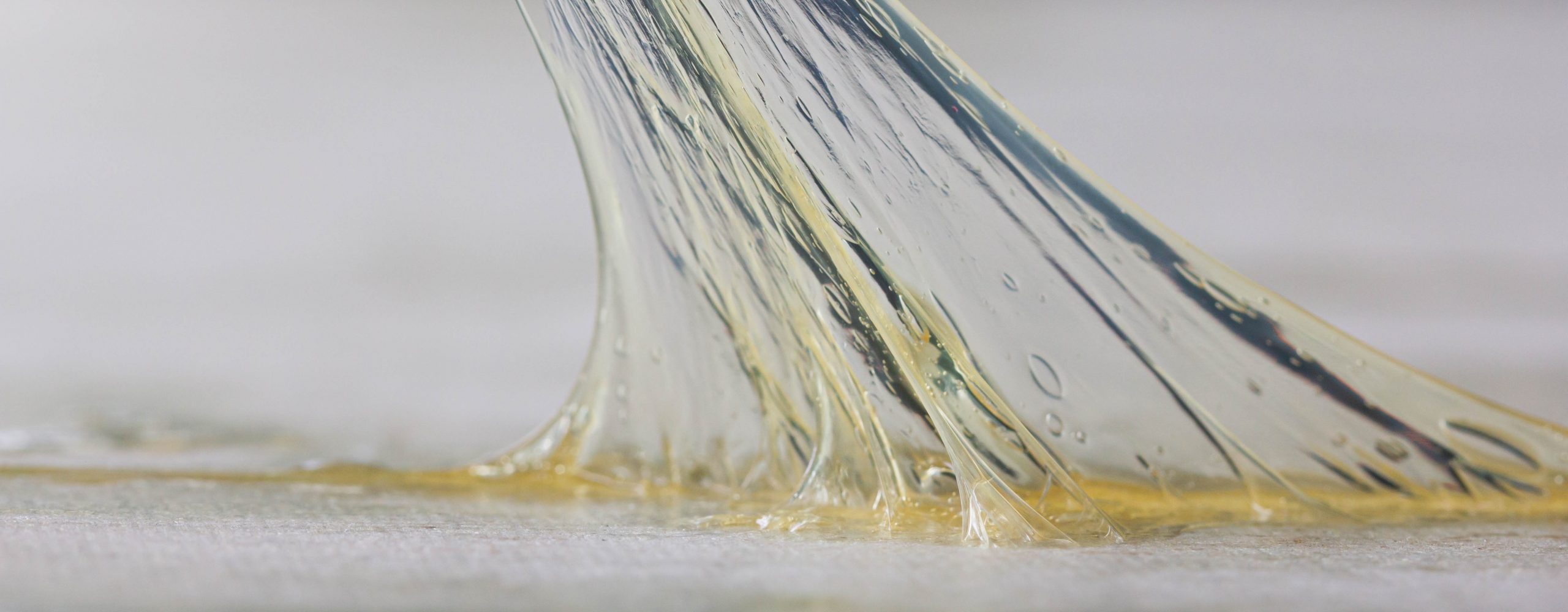

Asides from prolong drying time of water-based adhesives, they are safe and cheaper than the solvent-based. You can produce water based adhesives by combining water, polymers and additives. For solvent-based adhesives, mix solvents and thermoplastics such as acrylic or silicone. Use a high shear mixer to help you with that. It subjects the ingredients to intense high energy to make a stable and fine emulsion.

How do adhesives impact the environment – and are there alternatives?

The biodegradability of solvent-based adhesives is significantly low. The chemical wastes are not eco friendly and, as such ,affect the soil, water and air. A good number of manufacturing industries produce solvent-based adhesives because of their high substrate affinity.

Consider sustainable options like beeswax or gum arabic in place of non-renewable adhesives. Gelatin, an animal collagen, is biodegradable, but involves different manufacturing process and equipment other than adhesive making machine. It usually involves pre-treatment with acid (hydrochloric acid) or alkaline (sodium carbonate) to remove minerals and impurities. The extraction kettle can help you with that. Countries like the United States do not allow the use of solvents like toluene and methylene chloride when producing adhesives due to their negative environmental impact.

From ceramics to packaging – trends in the adhesive market

The global hot melt adhesive market reached a value of US$ 6.75 billion in 2020. Looking forward, the market is expected to grow at a CAGR of 4.5% during 2021-2026. The packaging sector is growing and steadily driving the demand for hot melt adhesives. Asides from sealing purposes, the automobile industry uses it for car seat covers. Other rising demand includes flooring materials and ceramics. Apart from looking for better adhesive processing equipment, producers also regard the cost-effectiveness of making adhesives. Also, instead of oven drying or ultraviolet curing, manufacturers are opting for the Ebeam technology, which doesn’t produce volatile organic compounds (VOCs).

Which adhesives technology do you need?

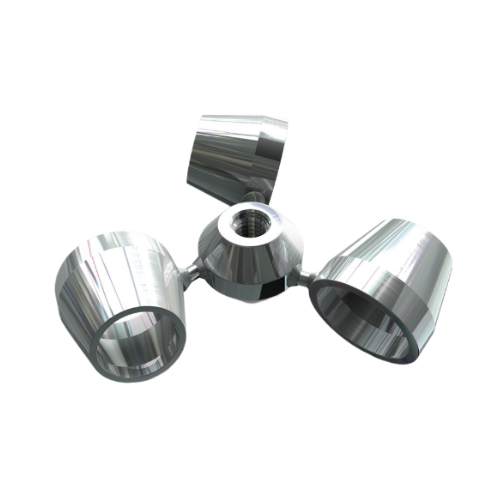

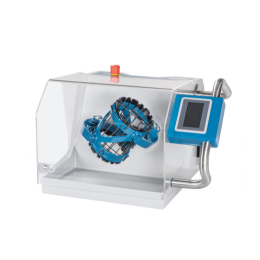

Dual asymmetric centrifugal processing system for epoxies and slurries

When working with highly viscous materials like ...

Compact plate evaporator for temperature-sensitive products

When dealing with temperature-sensitive or viscous products,...

Compact Mixing Plant for Paints and Coatings

A smooth finish in paints and coatings depends on the grade of dispersal duri...

Aerator for high-viscosity media

Highly viscous ingredients in both the food and chemical processing industries require spec...

Industrial robot for arc welding and adhesive applications

In automated manufacturing, achieving precise and efficient a...

Continuous-path arc welding robot

Ensuring high precision and speed in continuous-path applications like arc welding requir...

Adhesive nozzle cleaning system for automotive production

During automated adhesive applications in vehicle assembly, ma...

Gravimetric dosing systems for precise material measurement

In industries like chemical production or resin manufacturin...

Dual shaft mixer for high viscosity products

In industries such as adhesives, sealants, and cosmetics, mixing medium to hi...

Triple shaft mixer for high viscosity products

When producing high-viscosity products such as sealants, adhesives, or crea...

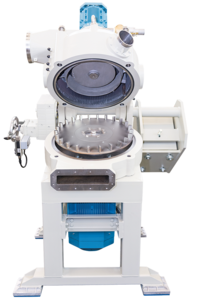

Coating centrifuge for small parts with oil and adhesives

In small parts production, ensuring an even coat of oil, paint...

High throughput twin screw extruder for low bulk density products

In industries where high volume production of materia...

Vacuum deaerator for elimination of gases

In industries where gas occlusions in liquids, semi-solids, and solids can affec...

Automatic single side adhesive labeling solution

In industries such as food, medicine, and cosmetics, the need for precise...

Double sides adhesive sticker labeling solution

In the mass production of beverage bottles and various packaging products,...

Dual asymmetric centrifugal mixer for epoxy and slurry mixing

In research and production environments, achieving consist...

Automated clipping system for flexible packaging

In high-speed industrial environments, efficient packaging of pumpable pr...

ATEX vacuum dissolver for high viscosity products

When dealing with high viscosity substances in a potentially explosive...

Two-component static-dynamic mixer for high-viscosity materials

Mixing compressible, two-component materials with differ...

Modular dispenser for dosing adhesives and abrasive media

Efficient adhesive and abrasive media dosing in industrial app...

Precision 2k dispenser for automated systems

When working in automated production lines, achieving precise dispensing with...

Dispenser for reactive material applications

In manufacturing environments such as e-mobility or battery production, the h...

3d print head for high-viscosity fluids and pastes

In the field of 3D printing, handling high-viscosity fluids and abrasi...

Homogenizer for low to medium viscosity media

In many manufacturing processes, ensuring a consistent and homogeneous mixtu...

Live bottom extruder for processing sealants and mastics

When processing entire batches of butyl, sealants, and other mas...

Belt dryers for gelatin processing

In the gelatin production industry, achieving consistent moisture content and ensuring h...

Disintegrator/dissolver mixing system for large solids

When handling the disintegration and solubilization of large solid...

R&D shaker mixer for battery powders and chemicals

Material heterogeneity, agglomeration, and contamination are key param...

Conditioned seed drying machine

It’s essential to dry moist seeds before you process and store them. Seeds with too high or ...

Tray erector

Corrugated trays come in many forms and sizes. Automate the process of erecting the trays to ensure consistent q...

Wraparound case packer

Packaging companies need to pay attention to personalization in shape and design in addition to the at...

Tray former for various tray formats including trays with corner constructions

If you are looking to increase your sup...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Linear machine for wraparound label

Wraparound labels allow you to offer detailed information using a small space or fit ex...

Automatic can sealer

If you need to cap paint, glues, and solvents containers and are currently manually placing the lids, yo...

2-way diverter valves for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diverted...

Multi-way diverter valve for pneumatic conveying

Products conveyed through pneumatic conveyor lines often need to be diver...

Dense phase conveyor for normal wearing materials

Dense phase pneumatic conveying is used for powders, granules, and grai...

Dense phase conveyor for powders and granules

Some manufacturing and filling operations require a smaller pneumatic transp...

Airshocking hammer

Silos, hoppers, bins, and other containers can build up a layer of powdered product on the internal walls....

Wear resistant bends for pneumatic conveying

Bends in pneumatic conveyor lines cause load loss leading to lower flow rates...

Lid applicator for corrugated cases

For your secondary packaging, you may be considering packing into boxes that require a ...

Deduster for injection moulding

High quality injection molded plastic parts require clean bulk resins free of dust and strea...