Battery Making Equipment

Find innovative batteries equipment and connect directly with world-leading technology suppliers

The battery revolution is as old as the industrial revolution. But batteries only emerged as a viable power source with lithium-ion solutions in the last quarter of the 20th century. Today, anything from power tools to automobiles runs on batteries, but advances in battery making equipment are eyeing more ambitious undertakings. Will we ever see battery-powered container ships? Will Battery Energy Storage Systems grow grid-scale successfully? Production technology is steadily moving towards this vision.

Technology picks for battery making

Lithium-ion battery powder processing solution

In industries focusing on next-generation lithium-ion batteries, the proces...

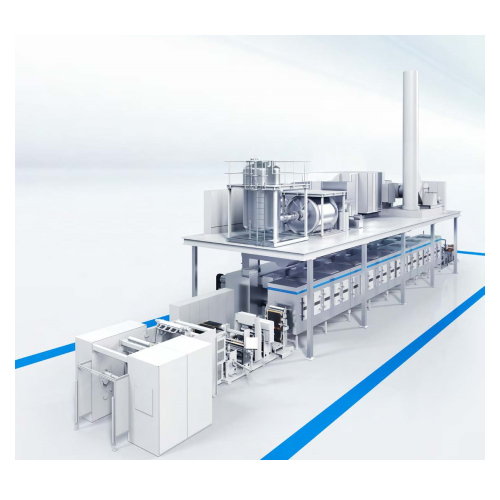

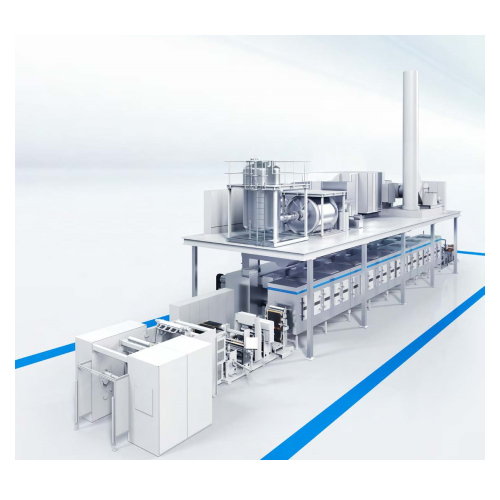

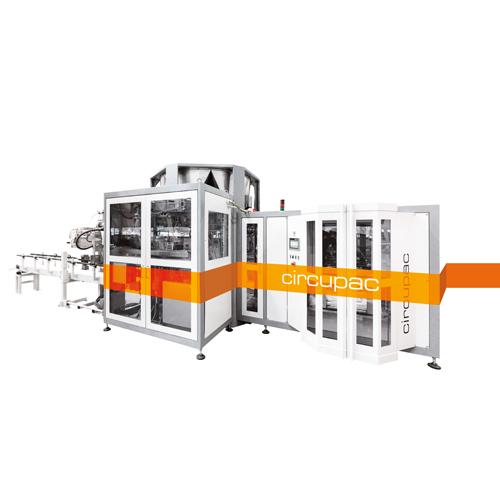

Electrode coating system for lithium-ion batteries

In the production of lithium-ion batteries, achieving consistent and p...

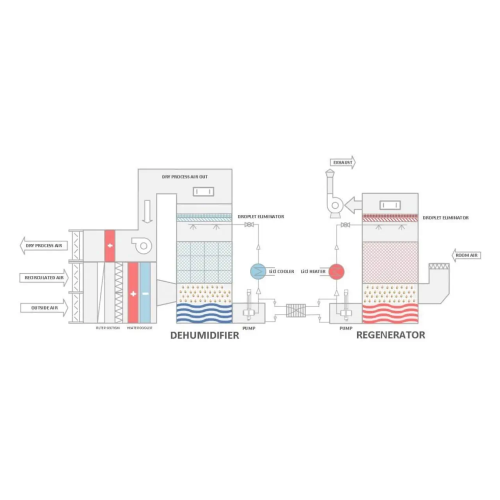

Industrial lithium chloride dehumidifier

Managing indoor air quality is crucial in sectors such as food processing and phar...

Spray dryers for lithium iron phosphate powder production

In the automotive industry, transitioning to electric vehicles...

What are you making?

Tell us about your production challenge

Reduce the surface area of materials with ultra-fine milling solutions

The battery chemistry determines the performance of the lithium-ion exchange. But the treatment of the materials significantly impacts the energy storage parameters of the final battery cells.

Battery manufacturing technology includes specialized mills to reduce the particle size of materials and increase their surface area. Grinding your chemicals into ultra-fine powders expands a battery pack’s overall capacity and recharge speed.

Distribute particles evenly with specially-designed battery making equipment

Lithium-ion batteries involve more than lithium, and the cornerstone of the manufacturing process is distributing materials homogeneously.

Milling equipment for ion battery production facilitates uniform dispersal by downsizing the minerals into ultra-fine powders. But particle size is only one-half of the effort. The materials must be mixed thoroughly but gently to achieve a consistent base for the electrodes.

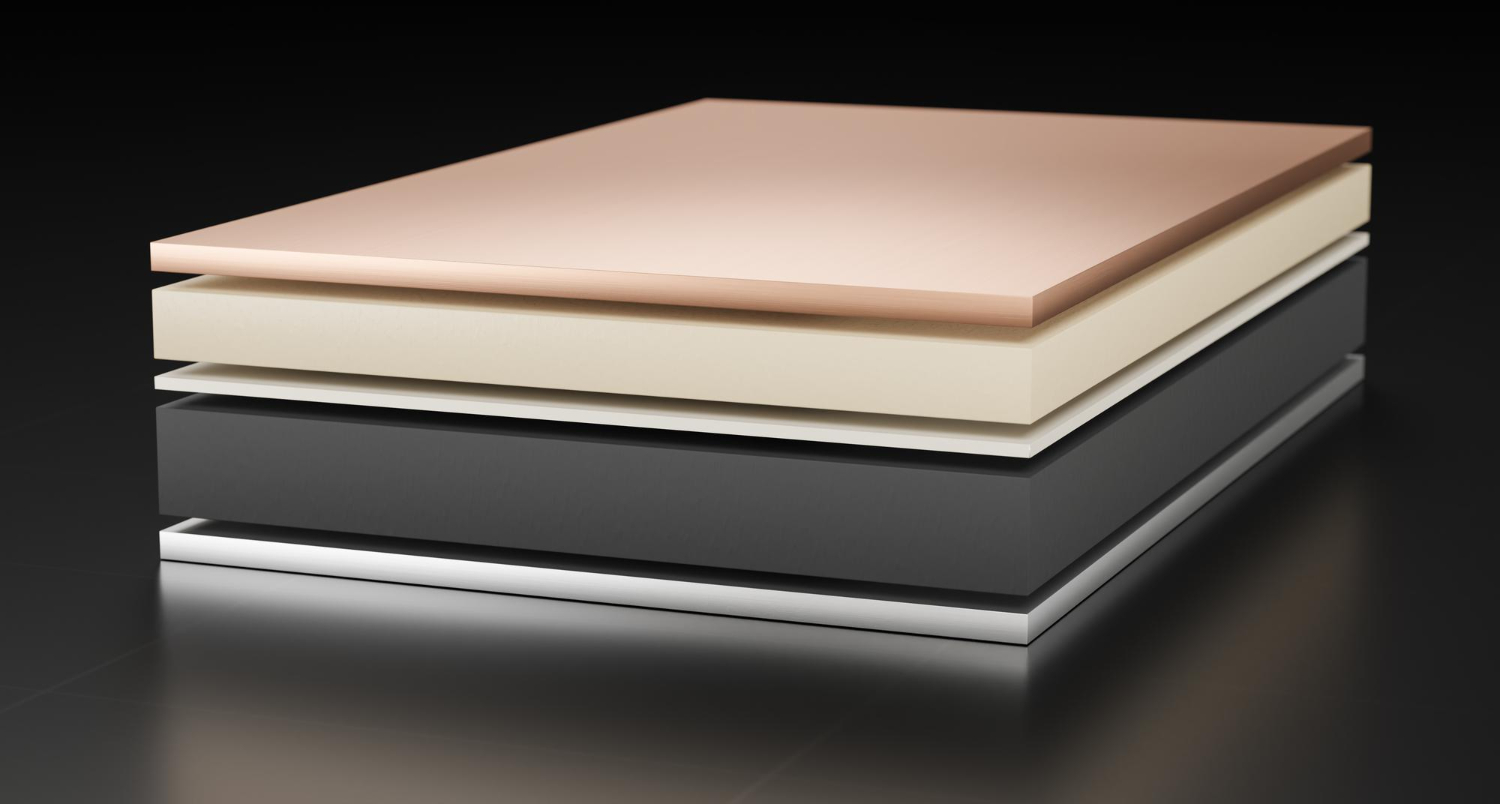

Combat lithium dendrite with solid-state battery types

The early wave of electrolytes for lithium-ion batteries were liquid solutions enriched with dissolved salts, acids, or alkalis. But elevating temperatures, particularly while charging the battery, generates internal pressure and produces dendrites.

Solid-state batteries reduce this problem by replacing the liquid electrolyte with a ceramic plate that acts as a physical barrier. Repeated charging cycles still cause dendrite growth, but the solid-state technique offers further advantages. Batteries are lighter, charge faster, and are simpler to recycle.

Round the graphite off to manufacture high-performance anodes

Graphite is the material of choice for most battery anodes as it is sourced relatively easily. But its effectiveness and storage capacity can be enhanced by rounding the particles.

Dedicated battery making equipment, such as classifier mills, apply mild pressure to achieve precise spheroidization. Natural graphite is usually highly irregular in shape, but the synthetic alternative still needs to be rounded.

Finish cathode production with a protective layer

The electrolyte transports the ions between the electrodes but also causes surface erosion of the materials. One strategy to minimize the wear is to coat the cathode and anode with a passivation layer.

Manufacturers apply various coating materials such as carbon black, zirconium dioxide, or magnesium oxide. Use high-shear mixing technology to coat the electrode material entirely and homogeneously.

Which batteries technology do you need?

Electrode coating system for lithium-ion batteries

In the production of lithium-ion batteries, achieving consistent and p...

End of line testing for industrial batteries

Ensuring the reliability and safety of industrial batteries is critical durin...

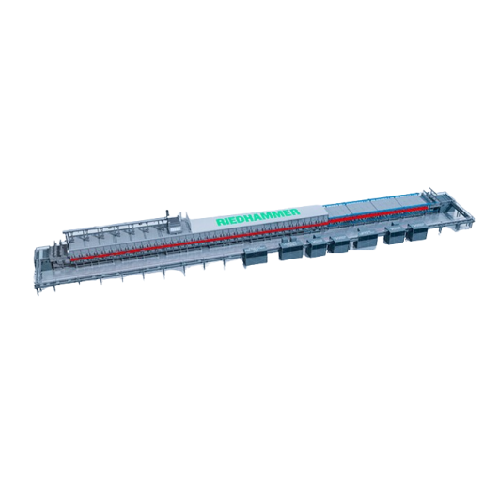

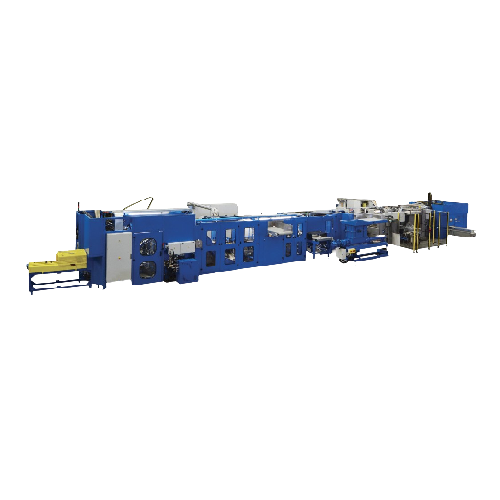

Battery plate finishing line for lead-acid batteries

In the manufacturing of lead-acid batteries, creating uniform and co...

Powder handling systems for battery production

Producing high-quality batteries requires precise handling of powdered mate...

Autonomous mobile robot for flexible production

In modern manufacturing environments, processes are dynamic and often requ...

Autonomous mobile robot for precise positioning

In industries like shipbuilding, aviation, and wind turbine manufacturing,...

Automotive assembly and leak testing systems

In the automotive industry, ensuring that assembly and testing processes are ...

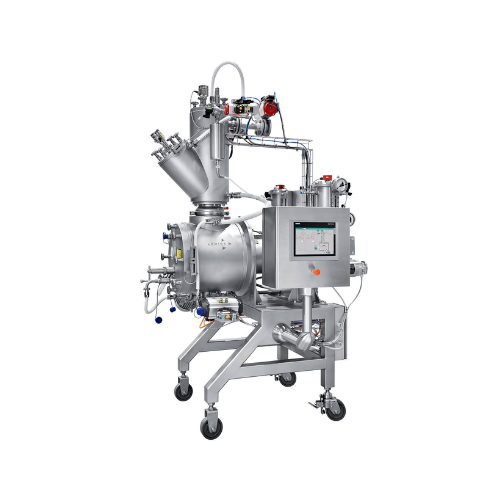

Super high shear mixer for nano to micron powders

In scenarios where precision powder mixing, particle surface modificati...

Laboratory system for powder and particle processing

In experimental and early-stage product development in various indus...

Automated bolting system for electric vehicle production

In electric vehicle manufacturing, precise and efficient bolting...

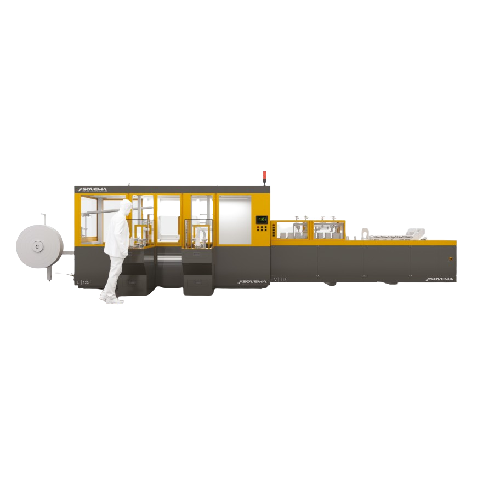

Battery electrode coating line

In the production of lithium-ion batteries, precise and efficient electrode coating is critic...

Spray dryers for lithium iron phosphate powder production

In the automotive industry, transitioning to electric vehicles...

Industrial rotary press for single-layer tablet production

In industries requiring precise and consistent tablet formati...

Battery production facilities with precision weighing

In the production of batteries, achieving high product purity and p...

Paste mixer for battery manufacturing

Battery manufacturing involves precise preparation of electrode materials, which requ...

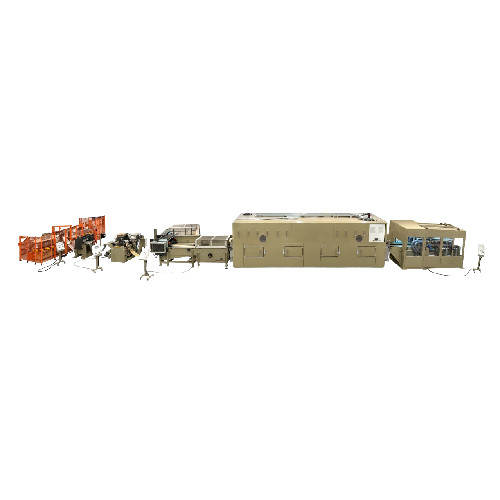

Pasting line for e-bike plates

In the production of e-bike batteries, the need for consistent, high-quality plate pasting is...

Battery chargers for industrial applications

In the efficient operation of industrial facilities, managing the charging pr...

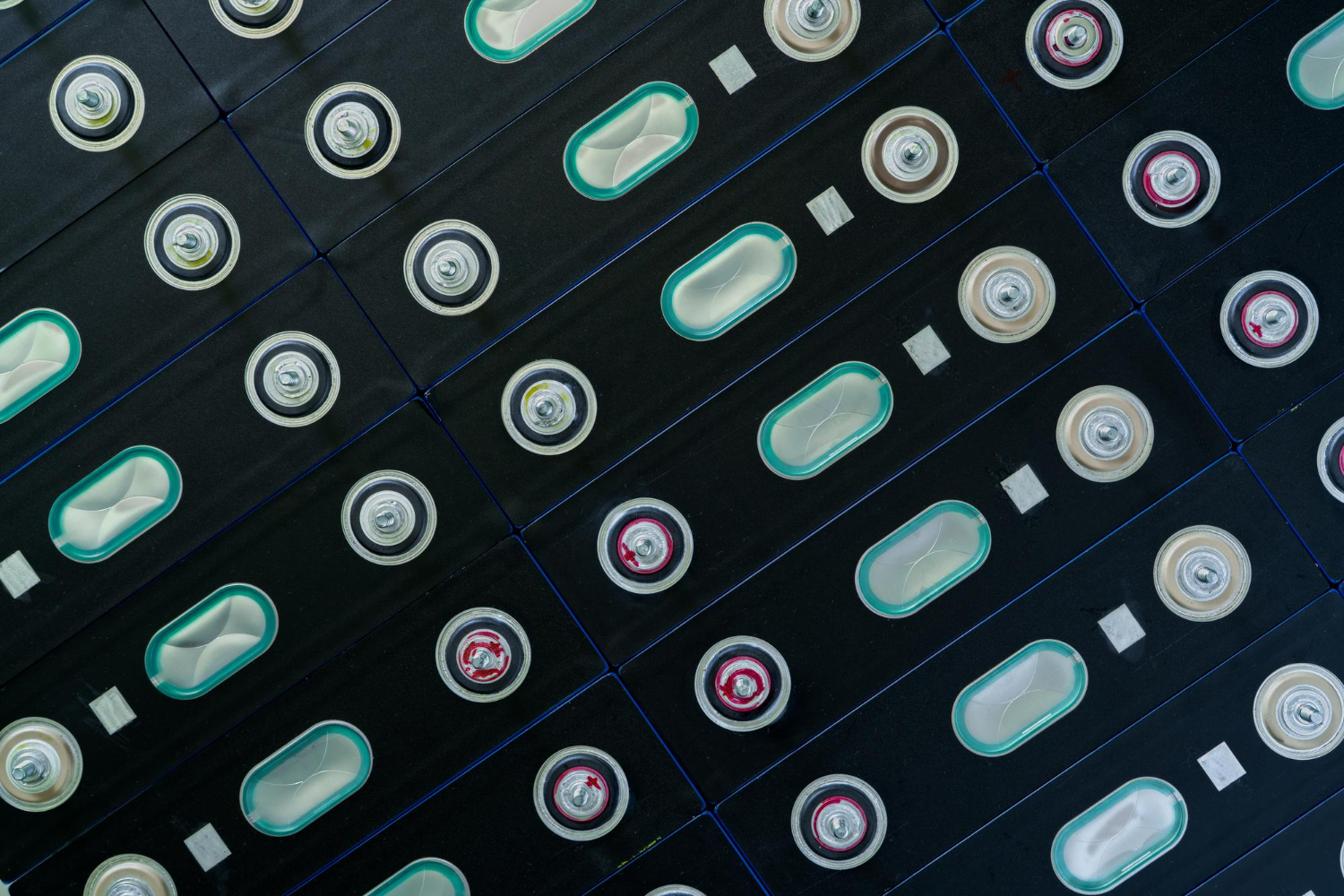

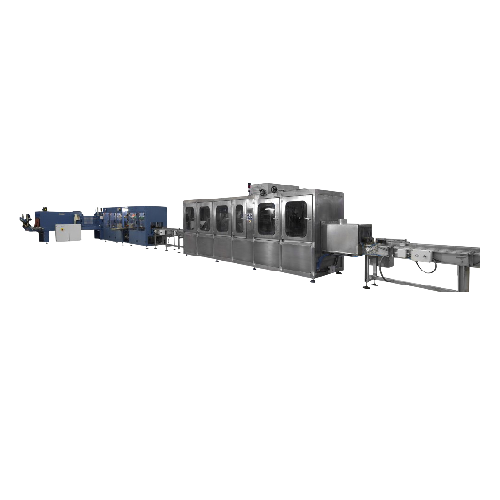

Water bath formation system

In the battery manufacturing industry, precise control over the formation process is essential. ...

High-density battery chargers

In industrial facilities, ensuring that batteries for heavy-duty equipment are charged efficie...

Industrial belt paster for battery manufacturing

In the battery manufacturing industry, ensuring uniform paste distributio...

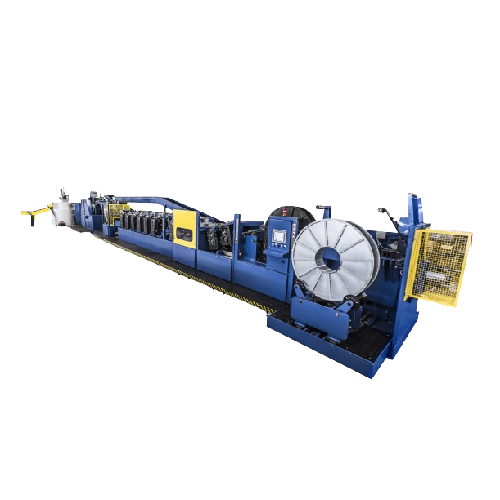

Lead strip manufacturing line

In battery production, achieving high-precision lead strips is crucial. Lead strip defects can...

Lead oxide mill for battery production

Manufacturing lead-acid batteries requires the consistent production of lead oxide. ...

Industrial battery curing chamber

In the battery manufacturing industry, ensuring the longevity and performance of batterie...

Industrial dry charge oven for battery manufacturing

In battery manufacturing, consistency and efficiency are critical wh...

Eft chargers for industrial applications

In environments where battery-operated systems are critical, ensuring efficient an...

Lithium-ion battery powder processing solution

In industries focusing on next-generation lithium-ion batteries, the proces...

Single-use containment valves

From GMP and HSE perspective material transfer is critical for chemical and pharmaceutical for...

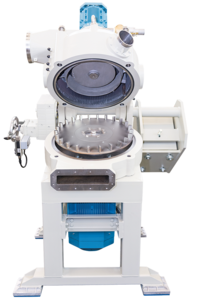

Continuous centrifuge for lithium hydroxide

Lithium hydroxide, a lithium compound used in making lithium batteries, is ind...

Automatic blister sealing machine for retail products

Blister packages for retail are usually designed with a paperboard ...

Industrial blister packaging machine for retail products

A blister can be simply defined as a type of packaging that cons...

Graphite spheronization system for battery production

In high-performance battery manufacturing, achieving high energy de...

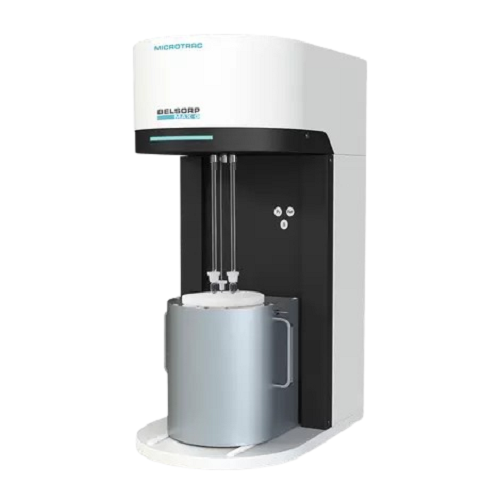

Specific surface area & pore size analyzer for materials

For detailed material characterization, understanding the specif...

Catalyst characterization analyzer

In research and development, evaluating catalysts accurately is crucial for optimizing p...

Gas pycnometer for true density measurement of solids and powders

In industries such as battery materials, catalysts, a...

Vacuum paddle dryer for laboratory use

Laboratory-scale drying of various materials like suspensions, pastes, bulk goods, a...

Powder synthesis reactors for nanometer and micrometer particles

Industrial production of high-quality powder materials ...

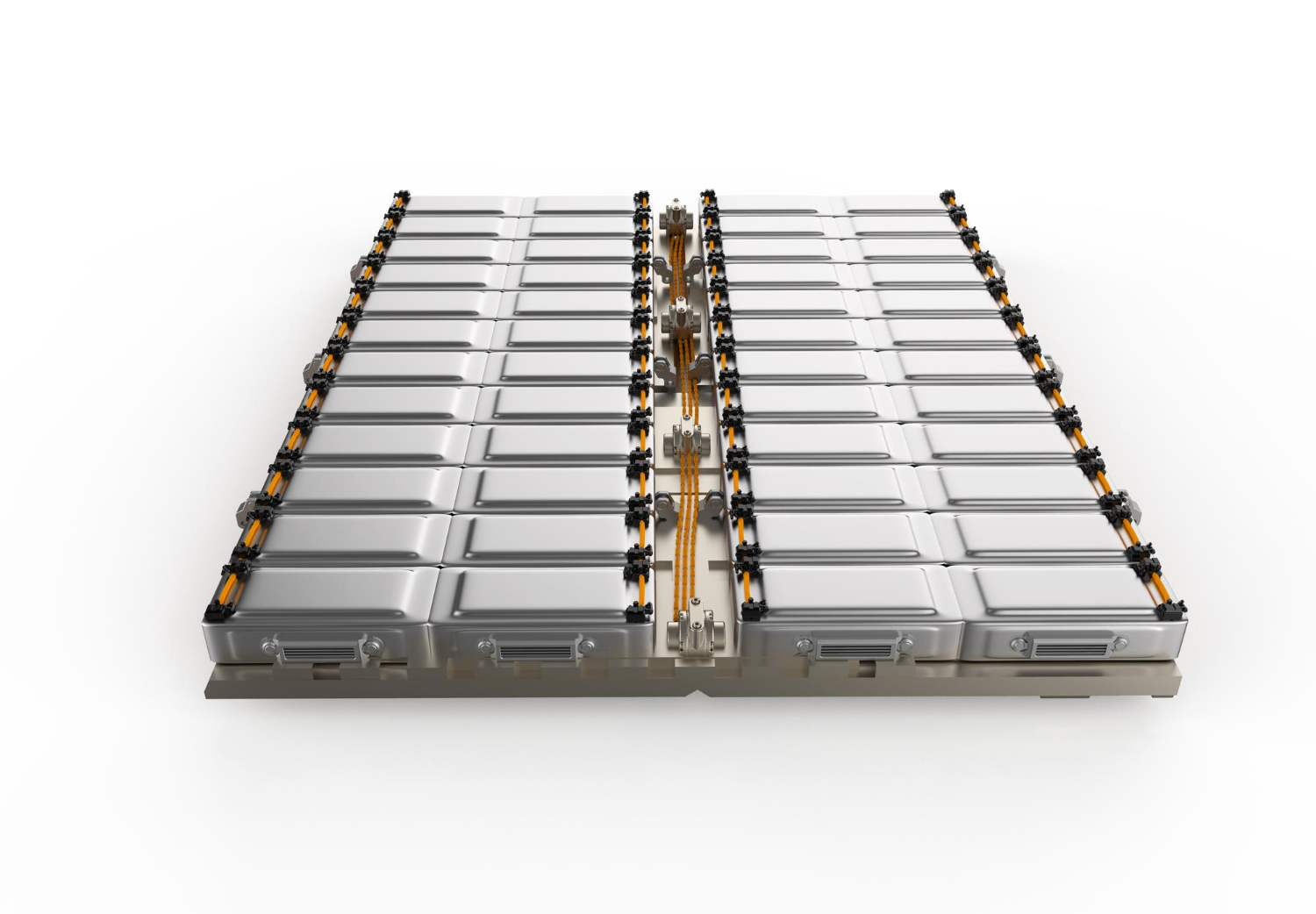

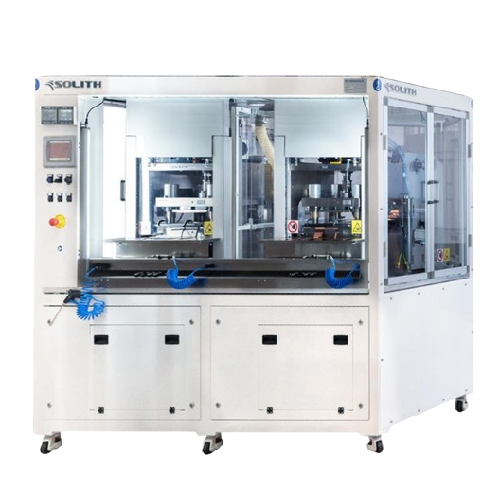

Production systems for battery cells with end-of-line testing

In the manufacturing of battery cells, ensuring quality co...

End-of-line battery pack testing system

In the electric vehicle industry, ensuring the reliability and performance of batte...

Roll support dryers for web transportation

In the manufacturing of materials not suitable for flotation, ensuring smooth a...

Solvent recovery systems for battery electrode manufacturing

Battery electrode manufacturing involves dealing with signi...

Industrial roller compaction for chemical applications

In industries where handling of fine powders and bulk materials is...

Dispenser for reactive material applications

In manufacturing environments such as e-mobility or battery production, the h...

Single piston food depositor

When handling the clean and precise portioning of various food types such as batters, soups, sa...

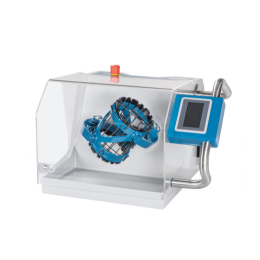

Glovebox for lithium-ion battery material processing

Processing lithium-ion battery materials necessitates a controlled e...

Pasting line for high-thickness plates

In industries requiring high-capacity battery production, ensuring consistent qualit...

Pouch li-ion cell assembly line

In the battery manufacturing sector, producing high-quality and reliable Li-Ion cells effici...

Punching machine for battery manufacturing

In the battery manufacturing industry, precision is paramount to ensure the lon...

Roll to roll notching equipment for battery production

In battery manufacturing, precise and clean notching of electrode ...

Wide strip casting and rolling lines

In battery manufacturing, precise and uniform strip casting and rolling are essential ...

Enveloping and stacking solution for battery manufacturing

In the battery manufacturing industry, assembly processes req...

Industrial grid gravity casting system

For manufacturers involved in producing battery grids, consistent shape, and uniform...

Industrial plate production line for battery manufacturing

In the battery manufacturing industry, producing high-quality...

Lead cylinder casting solution

In battery manufacturing, creating precise lead cylinders is crucial for ensuring reliability...

Cold lead cubing process

Battery manufacturing and recycling industries often face the challenge of converting lead into unif...

Solid flow meter for granular and powdered bulk materials

In chemical and infrastructure industries, accurate measuremen...

Loss-in-weight feeder for battery cell production

In battery cell production, handling materials safely while maintaining...

R&D shaker mixer for battery powders and chemicals

Material heterogeneity, agglomeration, and contamination are key param...

Ultrafine bead mill for battery materials

To facilitate the attainment of ultrafine particles and enhance electrode proper...

Inline solid-liquid mixer for battery production

In battery production, a critical phase entails mixing solids with liquid...

Inline solid-liquid mixer for chemicals and paints

Incorporating solids into liquids is a critical process in producing p...

Compact Mixing Plant for Paints and Coatings

A smooth finish in paints and coatings depends on the grade of dispersal duri...

Self-cleaning candle filtration system

Separating solids from liquids by filtration requires frequent cleaning or replaceme...

Automatic centrifuge for lithium carbonate

The battery industry requires high purity components. To obtain more than 99.5%...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Robot palletizing system

If you are a relatively large-scale producer, packing and transporting large quantities of products ...

Industrial liquid filtration system

Systems for the filtration of liquids with suspended solid contents can be challenging ...

High yield filter press

When a saturated slurry or sludge must be dehydrated with high yield results mining and other heavy i...

Dust and concentrate handling in smelting plants

Modern metal smelting operations involve extremely harsh conditions that ...

Circuit-air classifier

For high throughputs, with a fineness range of approx. d97 = 32 µm – 200 µm. Ideal for use in th...

Isolator centrifuge

For transferring highly active pharmaceutical ingredients (HAPI) without contamination from the isolator ...