What gummy are you making?

Find innovative gummies equipment and connect directly with world-leading technology suppliers

Gummies, a staple in the confectionery industry, can come in various forms, such as gummy bears, vitamin gummies, heart-shaped jellies, and many more mouth-watering alternatives. They are manufactured using specialized equipment for mixing, molding, coating, and packaging. From precise mixers to efficient packaging lines, industrial gummy production relies on a range of equipment to ensure consistent quality and meet consumer demand worldwide.

Top picks for processing gummies

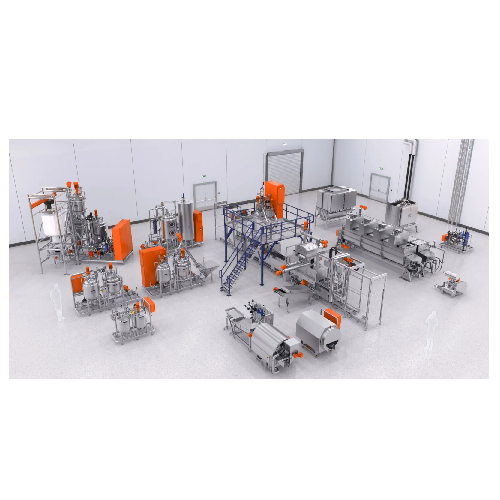

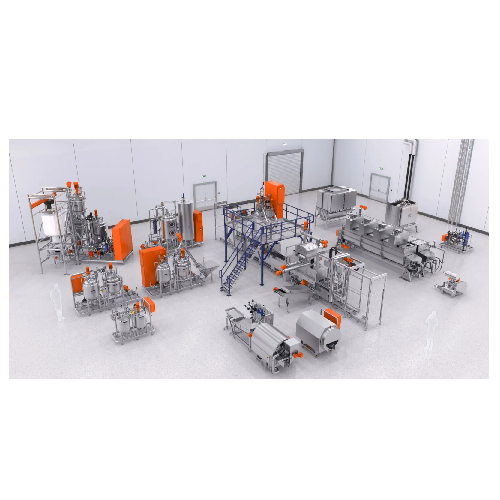

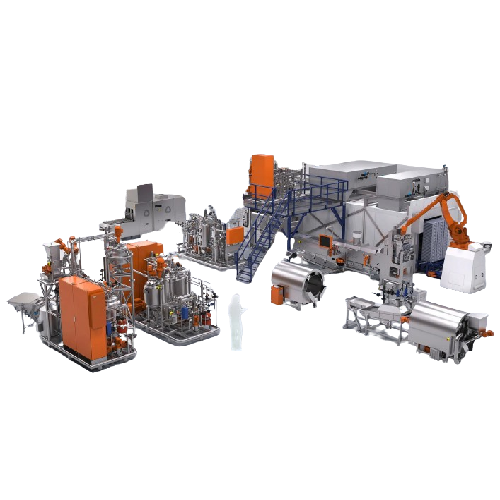

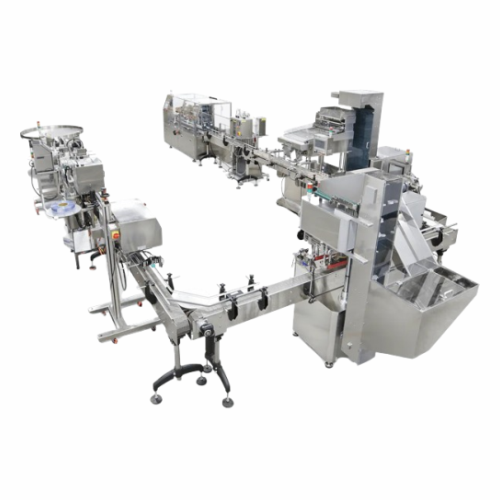

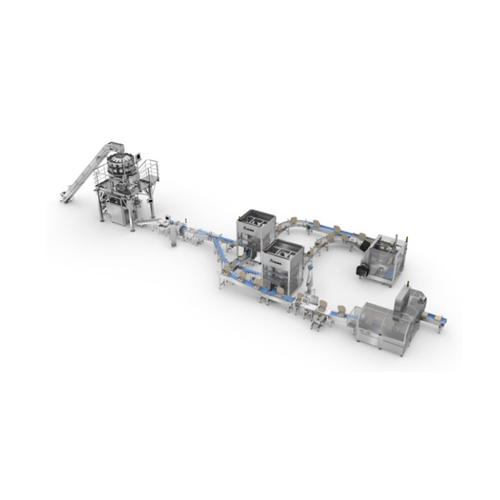

Automatic production line for gummies and nutraceuticals

In manufacturing environments with space constraints, the need f...

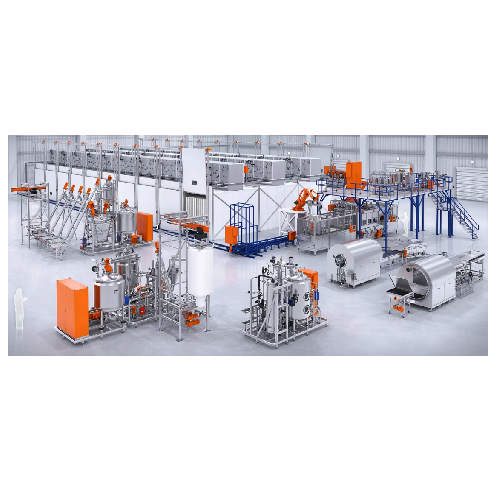

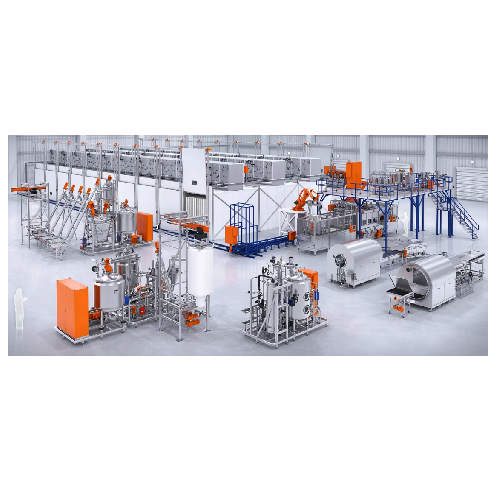

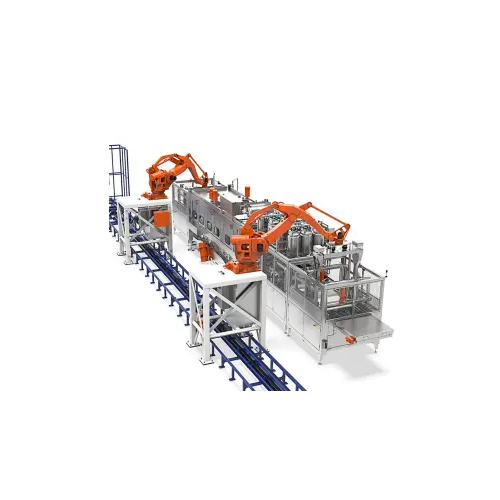

Robotic production line for gummies and nutraceuticals

In large-scale confectionery or nutraceutical production, achievin...

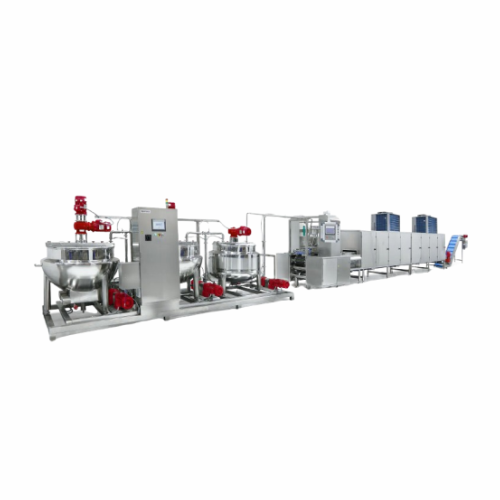

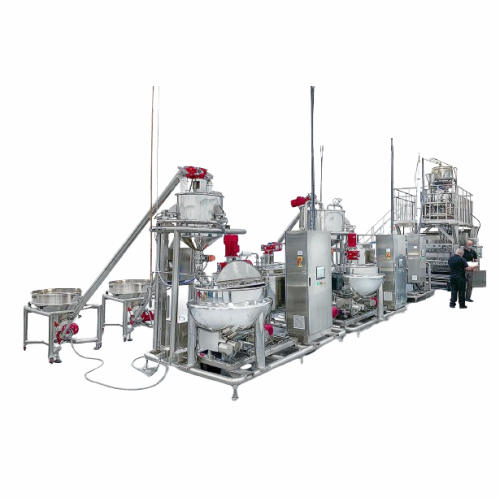

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

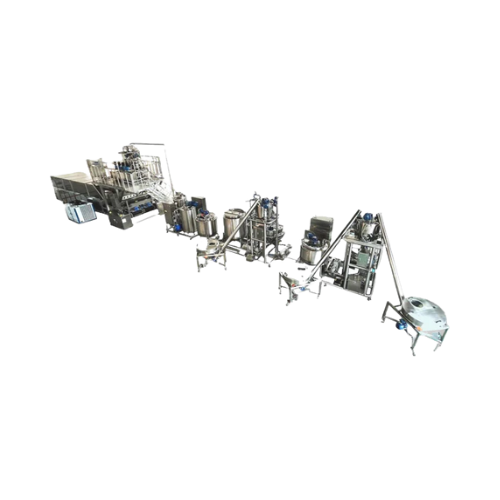

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Stories about gummies

Starting up your OTC non-starch gummy production

Starchless gummy depositing for limited risk on cross-contamination

Modular equipment that helps you grow organically

Making healthier gummy formulations

Chew on this: craft gummies with pectin

Enter the world of relaxation by making sleep gummies

Delving into the fungal fun of gummy goodness

Select your gummies process

What are you making?

Tell us about your production challenge

Making gummies on an industrial scale

Gummies are crafted from a thickening agent like gelatin or pectin, sweeteners, flavors, and colors. First you must mix the ingredients and then cook the gummy mass with an industrial cooker. Make sure that you spend time developing the right recipe to fit your gummy needs, otherwise your gummy mixture can turn out too sticky, cloudy or wet.

Next, you can mold the mixture into various shapes and sizes using high-speed molding machines. After molding, your gummies can undergo additional processing steps such as coating or polishing to enhance appearance and texture. And finally you can pack your sweet treats.

Start making functional gummies

In addition to being little sweet treats, gummies can also enhance wellness or serve as medicine. Therefore you can add functional and active ingredients to your gummy mixture, such as vitamins, Omega-3, CBD, active pharmaceutical ingredients (APIs), or even herbal extracts. Functional gummies can also promote hair growth or help you sleep better.

Producing them on an industrial scale requires precise gummy formulation, since the active ingredients can change the properties of the mixture. Adding an ingredient means balancing out the rest, and many functional ingredients, for example vitamins, require the addition of antioxidants, coloring agents, or buffer salts.

Formulation is key

Achieving uniform taste, texture, and appearance across large gummy and jelly batches requires precise ingredient measurement and processing control. Conduct thorough testing and stability studies on ingredients to ensure they maintain their quality throughout production and shelf life. You can also consider encapsulation techniques or alternative ingredient forms to improve stability of your gummies.

To make your production process more seamless use automated mixing systems and precise ingredient measuring equipment to ensure uniformity. You should also implement strict quality control checks throughout the production process.

Which gummies technology do you need?

Cooker for jelly and gummies production

In the confectionery industry, producing high-quality jellies and fruit gummies req...

Powder and oil coating system for gummies

If you need to coat large quantities of gummies with either powder or oil, maint...

Oil coater for gummies

In the production of gummies, achieving a uniform coating of oil or wax is crucial for product quality...

Sugar coating system for gummies

In the production of gummy candies, achieving an even and consistent sugar coating is cruci...

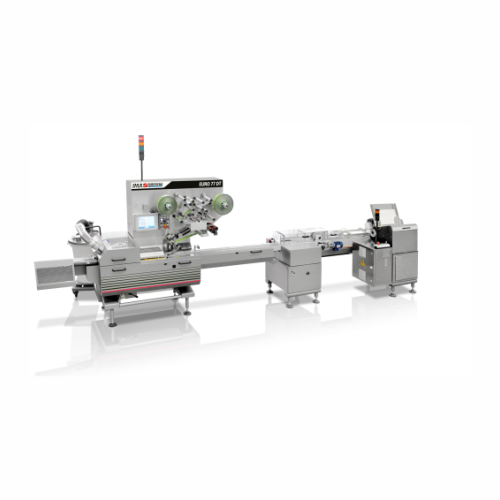

Automatic production line for gummies and nutraceuticals

In manufacturing environments with space constraints, the need f...

Fully-automatic non-starch production line for gummies

When producing large quantities of gummies, consistent shape and q...

Automatic production line for gummies, jellies, and nutraceuticals

Scaling up the production of gummies, jellies, and n...

Robotic production line for gummies and nutraceuticals

In large-scale confectionery or nutraceutical production, achievin...

Robotic high capacity production line for gummies and jellies

Producing high volumes of gummies, jellies, and nutraceuti...

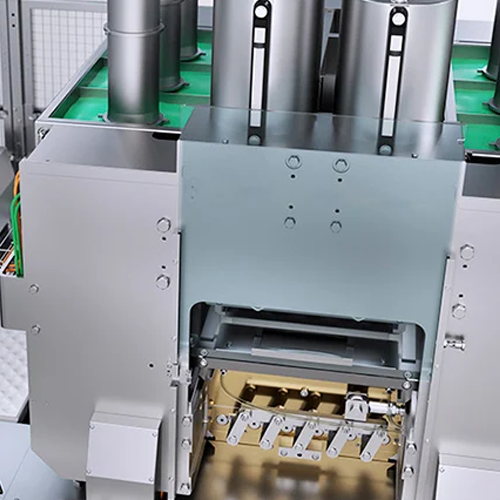

Candy packaging solution for gummies and hard candies

Ensuring the integrity and appeal of confectioneries during packagi...

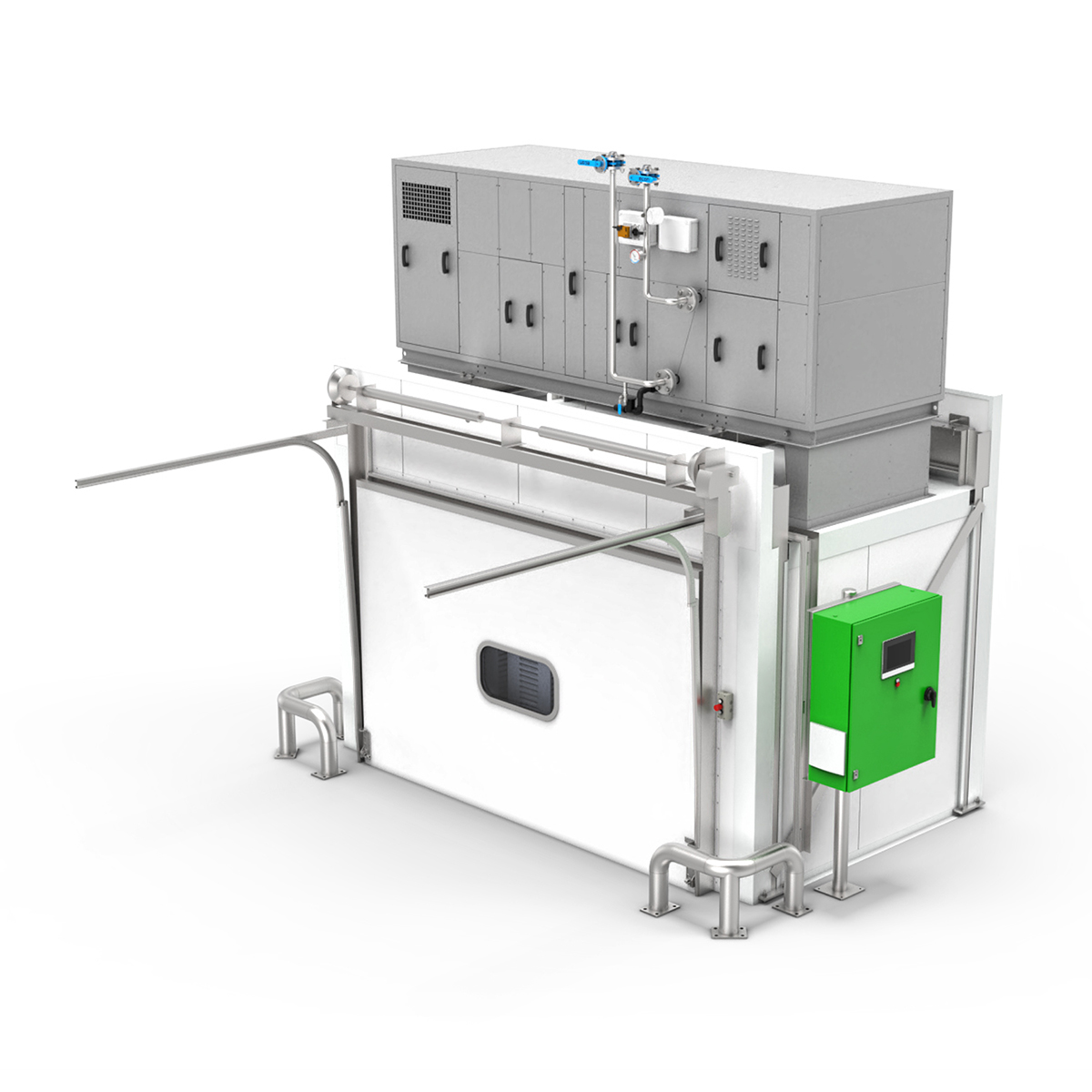

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental condi...

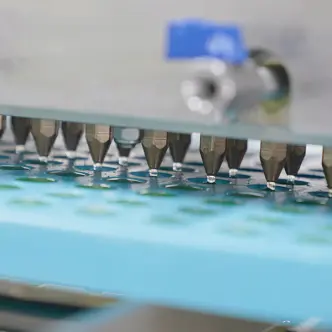

Entry-level starchless depositor for nutraceutical gummies

Manufacturing nutraceutical products such as vitamin, CBD ,or...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

Low Output Production Line for Gummies and Jellies

The original technique for making gums and jellies exploited the non-s...

Flexible Output Line For Gummies and Jellies

The traditional method for gummy and jelly production uses starch to keep the...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Dosing unit for automated mixing in of ingredients

In the production of jelly candies, managing the precise addition of c...

Automatic gummy production system

In the confectionery industry, producing high volumes of consistent-quality gummies can b...

Automatic gummy production equipment

Manufacturers of gummies are often challenged by the need to produce consistent, high-...

Packaging system for gummy products

In gummy production, ensuring properly sealed and accurately packaged products is essen...

Portable water activity meter for gummy production

In gummy production, controlling water activity ensures consistent pro...

Gummy counter for gusseted bags

Efficiently packaging gummies requires precise counting and placement into pre-made, gussete...

Automatic gummy manufacturing system

For medium-scale gummy production, maintaining high output while ensuring consistent q...

Small automatic gummy line

When producing gummies on an industrial scale, achieving high output while maintaining consistent...

High-capacity gummy production system

Managing large-scale production of gummies requires a system that ensures speed, cons...

Liquid confectionery metering system

In the production of jellies, gummies, and other confectioneries, precise mixing and m...

Mixing and metering system for candy production

In modern candy production, accurate mixing and metering of ingredients li...

High-capacity automatic gummy production line

Manufacturing high volumes of gummies, including CBD, THC, and vitamin-infus...

Automatic gummy candy production system

In the production of CBD, THC, and Vitamin gummies, achieving high production rates...

Sugar drum for coating gummy candy

In gummy candy production, uniform coating of sugar or wax is crucial for achieving a hi...

Gummy candy depositor for precision manufacturing

In a confectionery production environment, ensuring consistent shape, s...

Small-scale gummy candy depositor

When setting up a small-scale gummy candy production line, managing production efficiency...

High-capacity non-starch gummy and jelly production line

For manufacturers specializing in gummies and jellies with funct...

Industrial gummy and jelly production line

Large-scale production of gummies and jellies requires efficient, synchronized ...

Mid-capacity gummy and jelly production system

In the nutraceutical and confectionery industries, producing high volumes o...

Entry-level gummy and jelly production line

When starting to manufacture gummies or jellies with functional ingredients, m...

High output confectionery kitchen technology

Manufacturing high-quality confectionery, such as gummies and jellies, often ...

Start-up production line for CBD gummy production

High-value products like CBD gummies demand precision equipment such as...

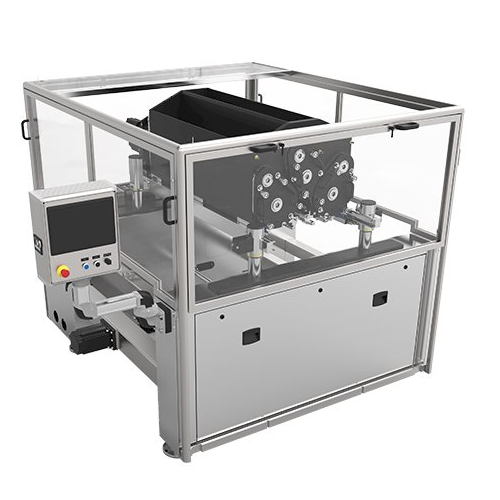

Lab scale production line for nutraceutical gummy production

By gradually investing in the individual parts, a productio...

Small-scale demoulder for starchless functional gummy production

Removing vitamin or CBD gummies from the moulds by hand...

Entry-level moulding machine for small to medium production

Small companies, medium-sized companies, and start-ups often...

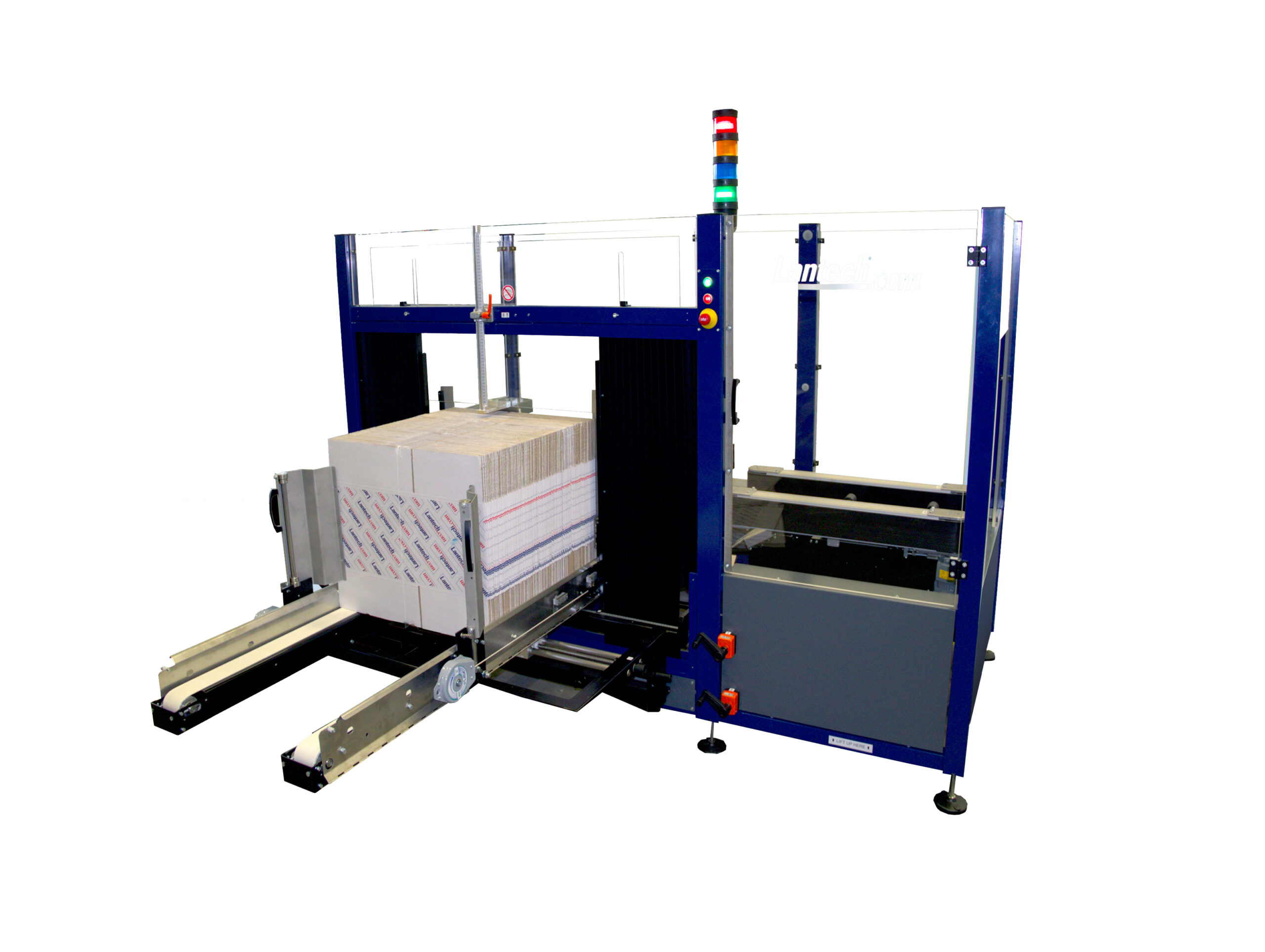

Vertical cartoning system for confectionery products

In the confectionery industry, maintaining productivity while accomm...

Intermittent vertical form fill seal for confectionery packaging

In the confectionery industry, achieving efficient and ...

Vertical baggers for confectionery packaging

In the confectionery industry, packaging solutions need to ensure product int...

High-speed flow wrapper for candies and gums

In the confectionery industry, packaging small items like candies, gums, and ...

Gum slabs flow wrapping solution

In the confectionery industry, efficient and hygienic wrapping of square-shaped gum slabs c...

Flow wrapping for bulk confectionery products

Handling small confectionery products coming in bulk can be challenging due ...

Automatic tray washer for gummy production cleanup

In gummy production environments, the accumulation of gummy residue on...

Waxing station for confectionery products

In confectionery production, maintaining product quality and appearance during s...

Cooling tunnel for confectionery extrusion

Efficiently cooling and conditioning extruded confectionery products to room te...

Multi-color and flavor confectionery production system

In the confectionery industry, producing licorice and fruit gum wi...

Hygienic pressure dissolver for high heat exchange

In the production of candies, maintaining consistent heat exchange pro...

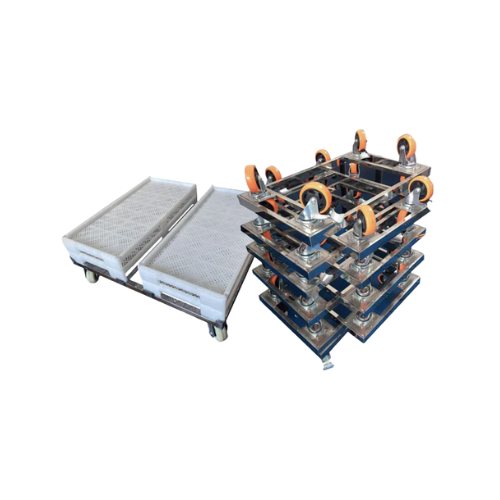

Drying trays for gummy candy production

In large-scale gummy candy production, ensuring proper drying and setting of soft g...

Dissolving tilt kettle for gummy candy production

In gummy candy production, consistent dissolution of ingredients such a...

Versatile confectionery cut and wrap system

In large-scale confectionery production, maintaining consistent sizing, cuttin...

Double twist wrapping solution for candy packaging

When producing preformed candies in large quantities, ensuring consist...

Extruder and depositor for confectionery production

Producing a wide range of confectionery products requires equipment t...

Depositor and extruder for confectionery production

Producing high-quality confectionery products requires precise contro...

Automated bagging system for confectionery products

Packaging confectionery products efficiently and consistently calls f...

Longitudinal slitting system for confectionery production

In the confectionery industry, achieving the correct width for...

All around sprinkling systems for confectionery

When producing various confectionery products, achieving uniform coating o...

Continuous mixer for pumpable media

In the food industry, mixing processes often involve solid and liquid combinations such...

High precision dosing system for liquid media

Producing confectionery and bakery products implies mixing large amounts of ...

Emulsifier and mixer for gelling agent

When making jams and marmalades, gelling agents, such as pectin, are used to thicken...

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Case erector

To overcome common cases of manufacturing variations and optimize your packaging line, you need to be able to cou...

Cooker for gums and jellies

Prepare your ingredients for use in gummy and jelly products. This is a static cooking system de...

Whipping machine for soft candy

Prepare your ingredients for any whipped or aerated product component. This is a pressurized...

Batch cooker for hard candy

Prepare your ingredients for the production of hard candy. This is a line of universal candy coo...

Pressure cooker for caramel and soft candy

Prepare your ingredients for soft candy production. This is a highly flexible c...