Soup Manufacturing Equipment

Find innovative soup equipment and connect directly with world-leading technology suppliers

Industrially manufactured soups gained traction in the 19th century when canning was invented and they have been warming us ever since. Whether it’s a classic ready-to-eat canned soup, condensed soup or a dry soup mix, soup manufacturing equipment for mixing, cooking, boiling, or sterilizing caters to every manufacturer’s production requirements.

Innovative solutions for making soup

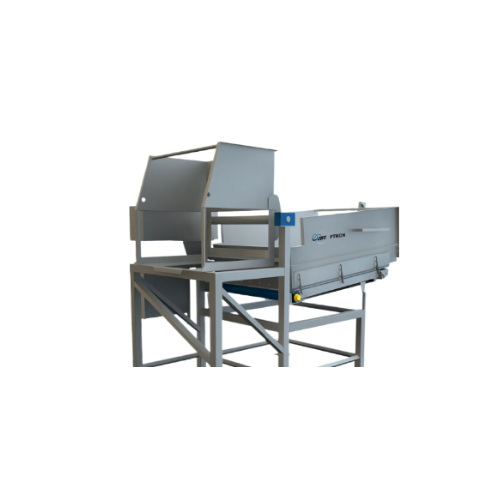

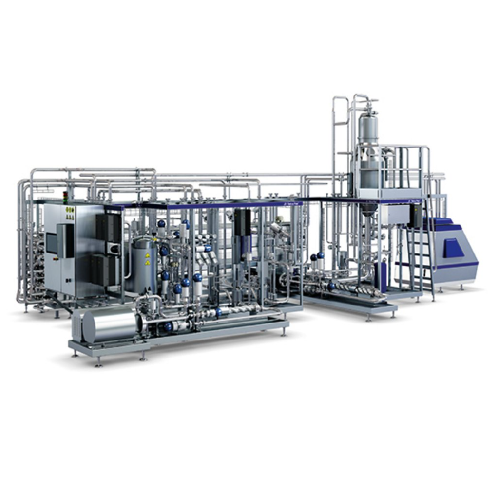

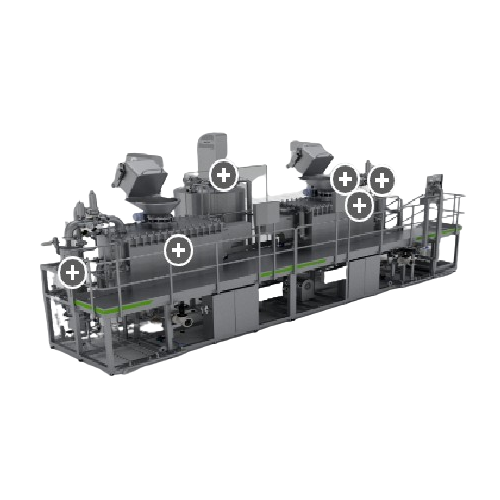

Automated soup production line

In response to the growing consumer demand for healthy, ready-to-eat soups, the need for adva...

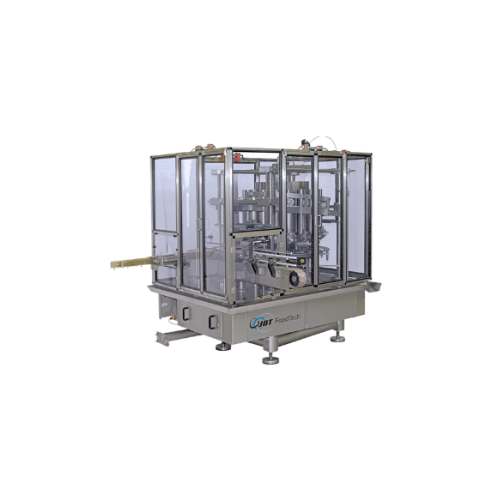

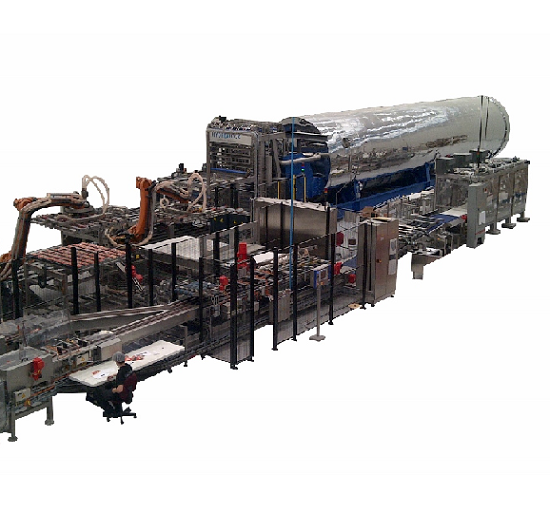

Cartoning solution for soup cubes

In the food packaging industry, especially for products like soup cubes, efficient packag...

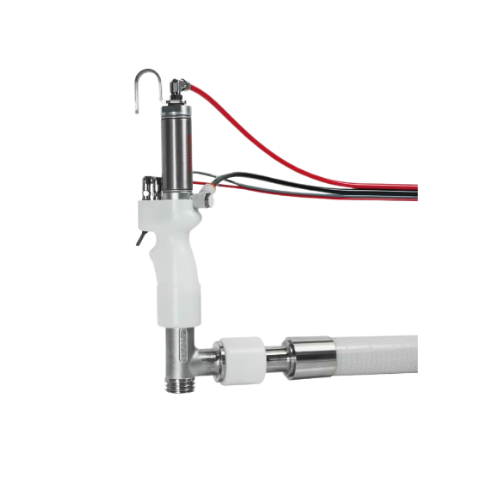

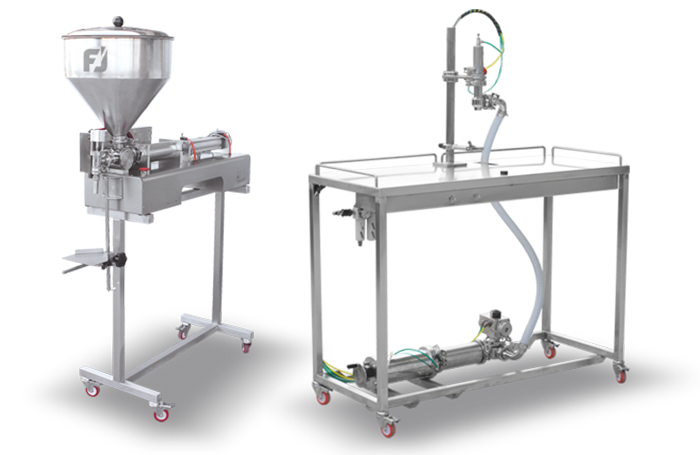

Automatic hot-fill dosing system for soups and sauces

In commercial kitchens and food production facilities, handling and...

Continuous heat exchanger for soups and sauces

In large-scale food production, maintaining consistent temperatures during ...

Select your soup process

What are you making?

Tell us about your production challenge

Different soups – different soup making equipment

Soups consist of various vegetables- potatoes, tomatoes, pumpkins, mushrooms, carrots and sometimes even dairy – all of which require different steps. In order to make soup, all ingredients must be properly cleaned, peeled, chopped and sliced into smaller pieces for optimal food processing.

As different vegetables are used and different soup recipes are formulated, changes must be made in the soup production line to include different equipment for pre-treating the vegetables. Potatoes and carrots must be peeled, while tomatoes are blanched to remove their bitter flavonols-rich skins.

After the ingredients are prepared, manufacturers can use different cooking techniques and soup making equipment like blanchers, steamers, stockpots immersion blenders and slow cookers, among others.

During blanching, vegetables are immersed in boiling water or steam before enzymes are deactivated. Some vegetables like eggplants need particular attention because they are sensitive to post-cooking browning. The problem can be avoided by adding antioxidants during blanching.

Soup can be further processed, depending on whether you are making ready-to-eat or dry mix soup. Ready-to-eat soup is deaerated to prevent oxidation and changes in color, while dry mix soup’s ingredients are dehydrated so they can be reconstituted with boiling water at a later date.

How does thermal processing affect vegetables?

Vegetables must undergo an industrial thermal process before being consumed. Heat treatment definitely brings benefits such as increased protective compounds, but it can also cause color degradation and losses of nutritional and soluble compounds (sugars and soluble fibers). Whether these conditions occur or not depends both on the characteristics of the vegetable to be processed such as enzymes or oxygen concentration and on the severity of the heat treatment.

For example, it has been determined that steaming reduces the loss of fat-soluble nutrients better than boiling. Instead, a study conducted by the Institute of Nutrition at Mahidol University in Thailand showed low losses in the vegetable’s β-carotene content when blanching, only 7-11%, while steaming, frying and boiling showed greater losses, 15, 18 and 43%.

To pasteurize or to sterilize?

There are two methods of removing microorganisms in the soup manufacturing process: pasteurization and sterilization. The choice between the two depends on the pH of the soup– most meat and vegetable-based soups have low acidity and manufacturers can fully sterilize them. In this case, sterilization temperature are above 100 °C and the product is then cooled down and transferred into previously sterilized packaging.

If the soup’s pH is in the acid range, pasteurization is recommended. Different temperatures for pasteurization are required to complement the pH range, for example if the pH range is between 3.4 and 4.0, the recommended temperature is 85°C. If it falls between 4.3 and 4.5, the recommended temperature for pasteurization is 99°C.

Soup in cans, pouches and trays

Canned soup is immensely popular owing to its versatile and recyclable packaging. After transferring the ready-to-eat soup into cans, can seamers ensure the product is sealed properly to prevent spoiling and spilling.

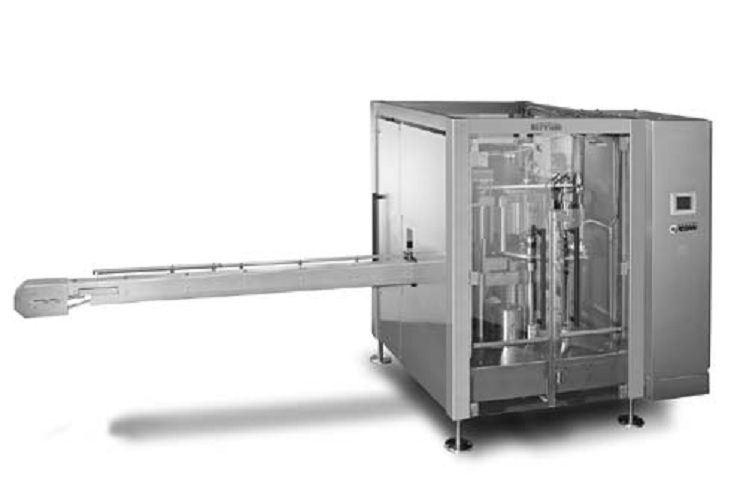

Since the invention of canning, soup’s packaging has evolved to plastic pouches that are re-sealable easy to use. High-speed stainless steel pouch packaging machines rapidly package liquid products into flexible pouches with great precision.

Soup trays are also gaining popularity because they can be frozen and microwaved, providing a single serving of soup. During the manufacturing process, trays are filled with soup and then sealed with tray sealers which secure the contents and prevent spillage.

Which soup technology do you need?

Continuous heat exchanger for soups and sauces

In large-scale food production, maintaining consistent temperatures during ...

Soup and sauce chiller for rapid cooling

In food production environments where soups and sauces are made, rapid cooling of ...

Hot-fill dosing system for soups and sauces

In commercial kitchens and food production facilities, efficiently dosing hot ...

Hot-fill dosing system for soups and sauces

In industrial food production, ensuring precise and safe dosing of liquid prod...

Automatic hot-fill dosing system for soups and sauces

In commercial kitchens and food production facilities, handling and...

Semi-automatic tray packing for soup cubes

In food production, especially in the packaging of hard soup cubes, ensuring ac...

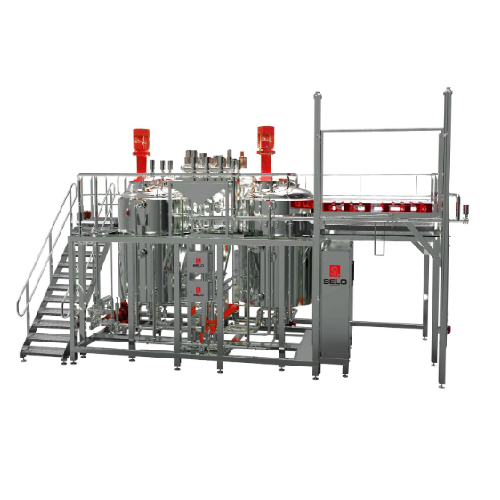

Mixing tank for soups, sauces, and dressings

When preparing soups, sauces, and dressings on a commercial scale, achieving ...

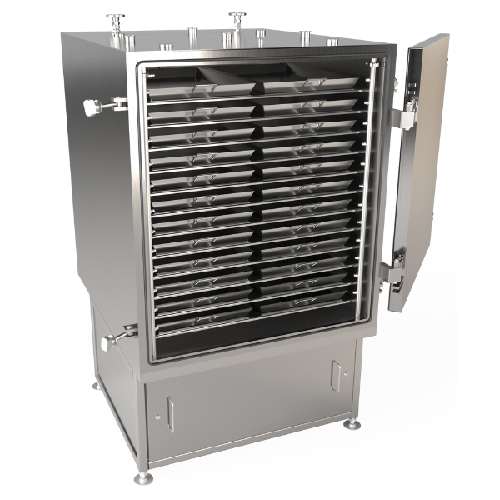

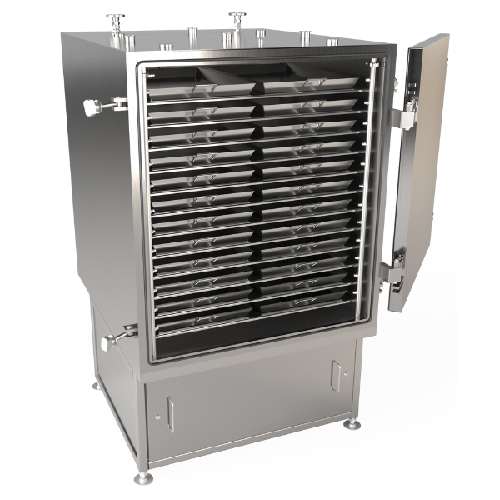

Industrial cooker for soups and ready meals

In various industries like bakery and ready meals, creating consistent, high-q...

Automated soup production line

In response to the growing consumer demand for healthy, ready-to-eat soups, the need for adva...

Precise liquid cooling solution for food processing

In the food processing industry, maintaining the integrity of flavors...

Industrial cooker for sauces and stews

In food production, achieving consistent quality and avoiding scorching during heati...

Efficient cooling and cooking systems for food processing

In food production, it is critical to maintain optimal tempera...

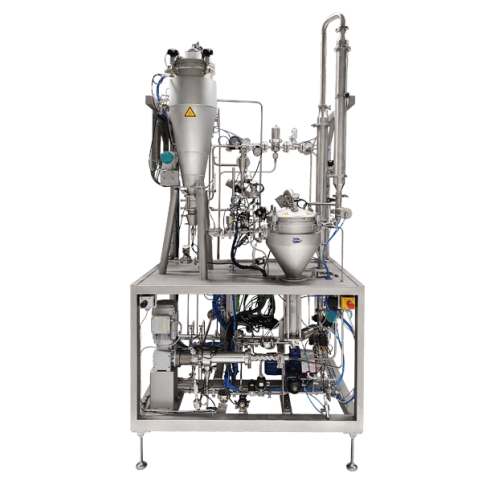

Compact production unit for liquid food products with varied viscosities

In the food processing industry, achieving con...

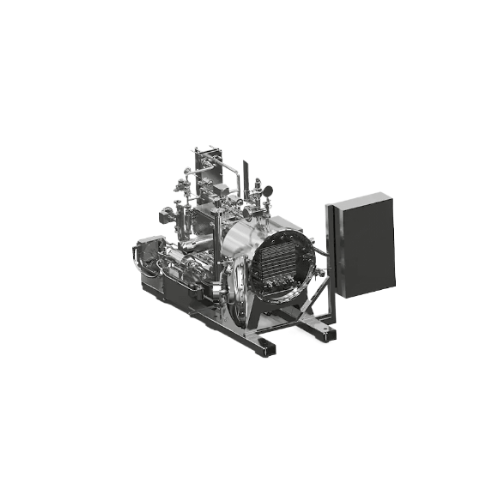

Aseptic thermal processor for high viscosity products

Managing products with high viscosity in industrial processing requ...

Direct steam infusion for high spore kill rate in sensitive food products

When processing sensitive food products, ach...

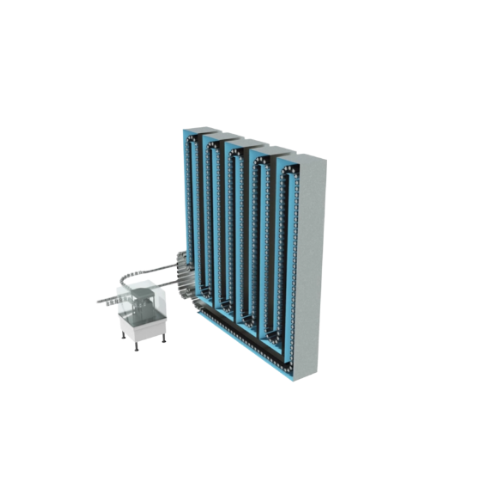

Pouch cooling system for food processing

In the food processing industry, rapidly cooling hot-filled soups, sauces, or chow...

High-capacity pouch cooling system

In food processing, cooling liquid food products like soups and sauces in pouches can be...

Heating and cooling system for food and dairy products

When processing food and dairy products, achieving precise tempera...

Conical buffer tank for hygienic dairy and food processing

In the dairy and food industry, ensuring hygienic and efficie...

Powder dissolver for large liquid quantities

When handling large-scale liquid processing in industries like food productio...

Ultra high temperature treatment system

In modern dairy and food industries, extending shelf life without preservatives is ...

Food dosing systems for industrial applications

In the food processing industry, achieving precise dosing of liquid and so...

R&d scale steam cooker for small batch processing

In food product development, testing various processing conditions on a...

Automated filter cleaning system for food production lines

Food production lines often face interruptions due to frequen...

Pipeline metal detection for pumpable products

In industries where liquid and viscous products are pumped through pipeline...

Stainless steel skids for food process integration

In food processing, integrating multiple steps such as heating, coolin...

Stainless steel buffer tanks for food, pharma, and cosmetics

Managing the intermediary stages between process steps ofte...

Stainless steel cooking kettle for food, pharma, and cosmetics

In industries like food, pharma, and cosmetics, preparati...

Aseptic filler for large bags

Industrial food and beverage producers often face challenges in filling large volumes of asept...

Production solutions for convenience foods

In today’s fast-paced world, the demand for healthy, prepared meals is on...

Vacuum high shear mixer for medium to high viscosity products

When producing high-viscosity products like ice cream or s...

Vacuum cooker-cooler for jams and sauces

Creating high-quality jams, marmalades, soups, sauces, and ready meals often requi...

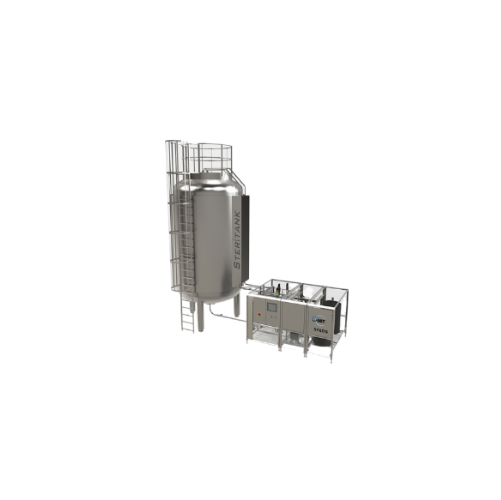

Aseptic storage tank for sterile liquid products

In the food and beverage industry, maintaining product sterility during i...

Electric bin tipper system for food processing

In food processing lines, transferring bulk products from bins to the produ...

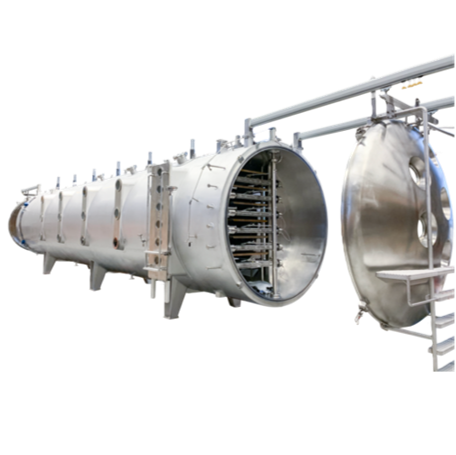

Hydrostatic sterilizer for continuous food processing

When industries need to sterilize various container types and sizes...

Heat exchanger for liquid and semi-liquid foods

In the food processing industry, maintaining precise temperatures during h...

Coil heat exchanger for dairy and beverage processing

In industrial food processing, maintaining product quality during h...

Efficient agitation system for retort packages

In food processing, especially when dealing with retortable rigid or flexib...

Volumetric piston filler for liquid and viscous products

In food processing, maintaining the accuracy of filling liquid o...

Aseptic bag filler for bulk containers

To ensure product sterility and extend shelf life, industries often struggle with co...

Rotary vacuum fillers for liquid and semi-liquid food products

In food processing, efficiently filling containers with l...

Single piston food depositor

When handling the clean and precise portioning of various food types such as batters, soups, sa...

Semi-automated depositor with handheld nozzle

In commercial kitchens and food production lines, achieving consistent porti...

High-speed blender for commercial use

In a commercial kitchen, preparing large quantities of smooth and consistent blends q...

Direct Uht processing for heat-sensitive liquid products

Producing high-quality, aseptic liquid food products often faces...

Coiled heat exchanger for high viscosity products

When processing viscous products like soups with chunks or dairy desser...

Continuous ultra-high temperature treatment for prepared food products

Producing consistent and safe food products such...

Food processor for high and low viscosity products

In the food processing industry, achieving consistent quality in recip...

High shear mixer for emulsification and powder dissolving

For industries involving the production of dairy products, bev...

Blending tank for food preparations

In the production of various food items such as soups, sauces, and desserts, achieving ...

High-speed form and seal machine for retortable food packages

In the production of retortable food packages, efficiency ...

Compact filling system for retortable carton packages

When producing retortable food products, achieving high output with...

Food processing scraped surface heat exchanger

In the food processing industry, achieving consistent heating and cooling o...

Automated sauce production lines

In food manufacturing, maintaining high hygiene standards and consistent quality is crucial...

Marmalade and Jam Processing Machine

When producing jams and marmalades, preserving the natural flavours, aromas and colors...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Continuous sterilizer for milk beverages

An important goal of heat processing in the manufacturing of milk beverages is to ...

Continuous sterilizer for pet food

Sterilization is a critical operation in the manufacturing of wet pet foods. An importan...

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Autoclave for doypack pouches

The self-standing Doypack and other similar pouch products are a very popular method of packag...

Can seamer for food products

Flexible can seaming equipment is required to adapt for product-specific variations in food can...

Pilot system for high-viscosity product processing

Processing high-viscosity products or products containing large fruit ...

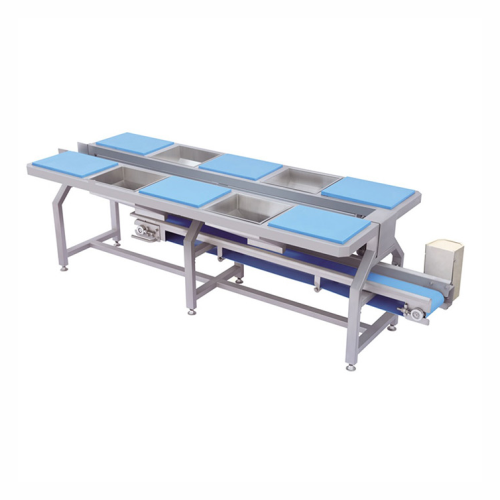

Vegetable and fruit preparation table

In food processing environments, efficient and hygienic handling of vegetables and fr...

Vegetable and fruit centrifugal slicer and shredder

In food processing, achieving uniform slicing and shredding of a wide...

Drum blancher for continuous cooking and blanching

In industrial food processing, achieving consistent and efficient cook...

Aseptic cooking and filling line with two reactors

When processing industrial broths, vegetable creams, or convenience fo...

Food depositor for large chunk applications

When handling thick mixtures like stew or pasta salad in an industrial food pr...

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

High-speed bouillon cube press machine

Mass production of bouillon cubes and tablets with very high output requires higher ...

Bouillon cube press machine for medium-range batches

The pressing stage during the production of bouillon cubes or tablet...

Mass flow air knife drying system for cans

For large-scale production of canned beverages, line throughput and efficiency ...

Industrial jam vacuum cooker

In a production setup of agri-food preserves, sauces, and other condiments, vacuum cooking at 5...

Capping Machine for Jars

In production lines that involve sterilization processes, jars that are not properly capped may expl...

Semi-Automatic Volumetric Liquid Filling Machine

Filling containers manually with liquid and viscous products is the metho...

Small Scale Industrial Jam Cooker

Production of marmalades, jams, fruit concentrates, and sauces requires multiple steps. T...

Batch cooker for fruit puree

The fruit pulp is used in many different bakery products, especially as a filling. Since fruit ...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Jam pasteurizer with temperature control

Microorganisms and pathogenic forms in fresh fruit jams can shorten storage time. ...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

Irregular can seamer

Quite some time can be lost adjusting the seaming process to different can sizes when orders keep follow...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

Entry level HFFS Machine for flat sachets

Traditional horizontal form fill and seal sachet machines for lower volume lines...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Air knife dryer for pouches

Flexible pouch packaging is a popular choice for many consumer food products. Before final print...

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Industrial food processor for cooking ready meals in different consistencies

In food industry production, the developm...

Easy to use food processor for gastronomy sauces and pastes

For the development and production of high quality gastronom...

Food processor for making fruit jams for pastries

In a bakery environment fruit jams are often used for the decoration or...

Multi-functional food processor for a high sugar percentage pastes production

For the development and production of hi...

Vacuum cooker for concentrating sauces and purees

When producing high quality prepared food, concentrating products for s...

Industrial tilting pan with cooling system

Raw materials need to be processed into finished, cooked products most quickly ...

Compact industrial sauce pan

Safe, reliable cookers that operate unobtrusively are required in any kitchen where space and t...

Industrial pressure cooker

Optimizing production processes and human resources to reduce energy consumption and save time an...

Industrial sauce pan

For the small and medium food industry, economical use of time, space and human resources is critical wh...

High performance can seamers for the food industry

The wide variation of materials and dimensions used in the food cannin...

Smart Industrial Sauce Cartoning System

Large volume producers of sauces and ready meals continuously pack different produc...

Complete cutting, mixing, emulsifying and heating system

From laboratory scale to large volume food or cosmetic productio...