Making Protein Powder

Find innovative production technology for making protein powder and connect directly with world-leading specialists

It took the scientific community almost 70 years to agree on the name ‘protein’ and discard the popular alternative, proteid. But protein powder processing still needed another five decades to be commercialized in the 1950s. Once extraction and purification could be industrialized, protein powder soon became a basic staple supplement.

Select your protein powder process

Tell us about your production challenge

Obtain higher protein purification with chromatography

A critical step in protein powder processing is purification from other biological elements found in the cell. Most purifying techniques apply fractionation methods such as centrifugation followed by decantation.

Column chromatography takes advantage of the physical properties of the protein mixture to offer a powerful purification method. You may either target the protein itself or the other elements in the liquid solution as it percolates through a solid phase.

Perform protein power processing at low temperatures

Animal-derived protein finds optimum stability at a temperature of around 37 °C. However, its behavior changes once it is brought out of the cells, even if the temperature is maintained

Protein extraction yields better results at about 4 °C. Low temperatures allow greater control of the elements in the solution, while enzymes employed to break up protein perform better in a cooler environment.

Add a buffering component in the solution medium to stop denaturation

Proteins are prone to denaturation once extracted from their natural pH conditions. Protect your extract by adding a buffering component to your solution. Biological buffers with an acid dissociation constant of around 7, such as phosphate, offer good protection.

In addition, reducing agents shield your protein powder processing from oxidation. Dithiothreitol (DTT) or 2-mercaptoethanol are typical reducing agents, but the former shows higher effectiveness.

Soy protein extract delivers complete digestibility

Vegetables are also a good source of protein. Peas, hemp, and rice offer popular alternatives to animal-based protein, but they lack amino acids that the human body cannot synthesize.

On the other hand, Soy protein is the only plant-based alternative that meets all the essential requirements. Soy protein registers the highest score for quality on the Protein Digestibility Corrected Amino Acid Score (PDCAAS).

Insect processing is emerging as an alternative protein source

Agricultural entomology has come to the fore as an efficient protein source. Cricket protein, in particular, has attracted attention for its adaptability to human consumption requirements.

The ecological impact of insect farming is significantly lower than either crop or animal farming. Not only does it require less space, water, and energy, but insects can be reared on clean agricultural by-products such as surplus grains.

Processing steps involved in protein powder making

Which protein powder technology do you need?

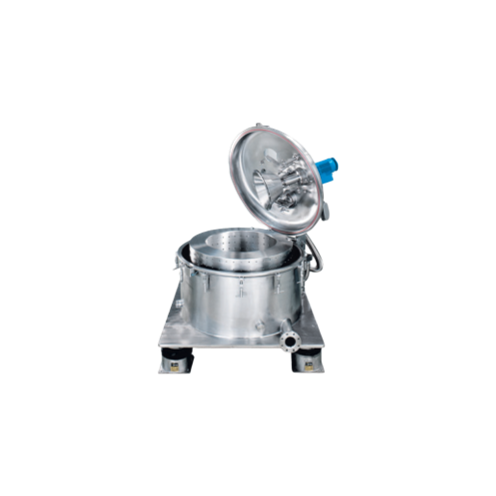

Clarifiers for plant protein recovery

In the food processing industry, recovering valuable plant proteins such as those fro...

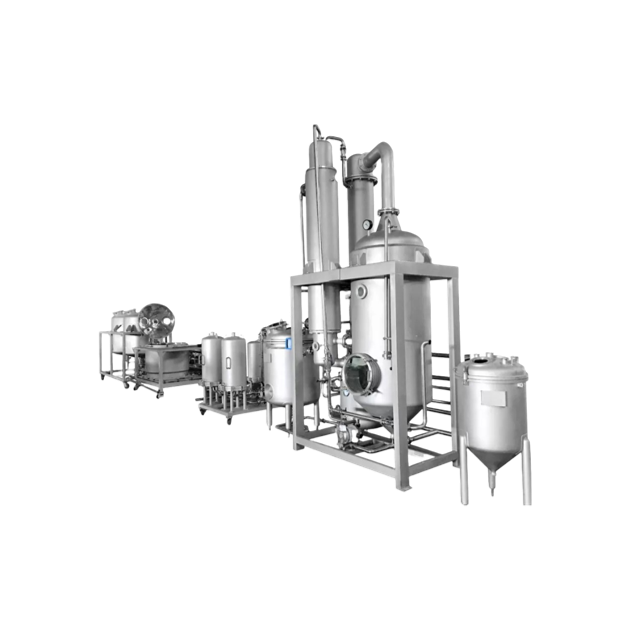

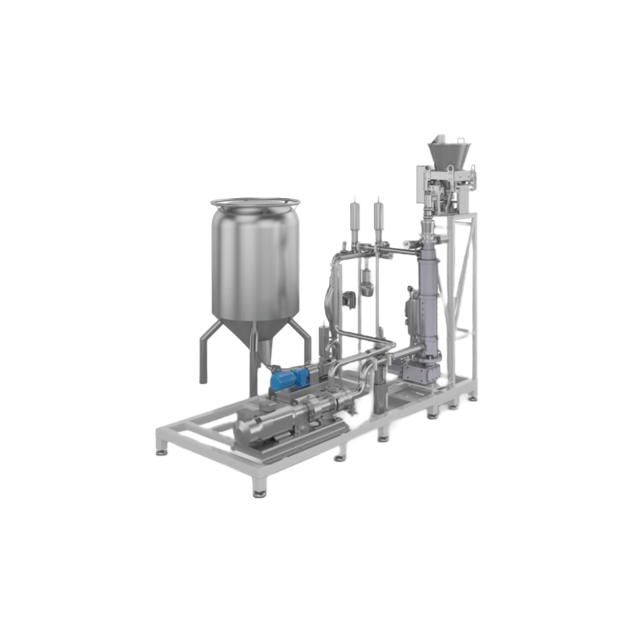

Soya protein isolate production line

Producing high-quality soya protein isolates is essential in various food industries, ...

Pilot spray dryer for high-value proteins and nutraceuticals

Developing high-quality protein powders or nutraceutical pr...

Powder characteristic evaluation

In laboratory and research environments, accurately assessing the flow properties and behav...

Modular big bag unloading station for various materials

When handling large volumes of powdered or granular materials, it...

Large-scale industrial freeze dryer

In large-scale commercial freeze drying, managing significant moisture content and larg...

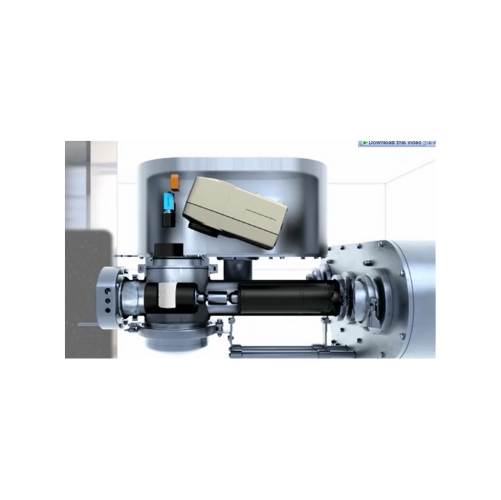

Decanter centrifuge for protein extraction

Protein recovery from meat, fish, and plant sources requires precise and effici...

Compressed air loaders for material conveying

A reliable system to transport materials like powders and granules from stor...

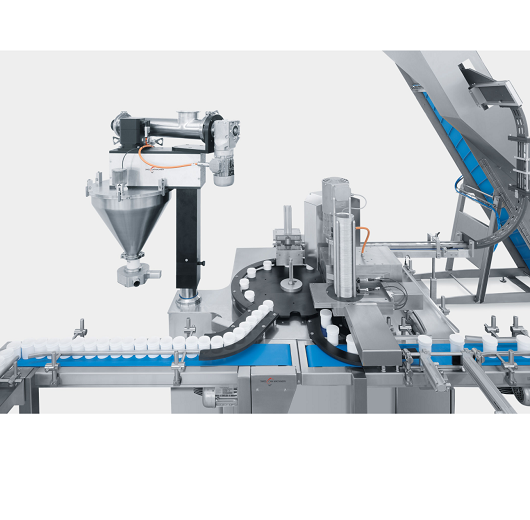

Automatic granular product weighing system

Precise weight measurement of granular products ensures product quality and reg...

Spray dryer for nutritional and dairy powders

In the food and dairy industries, maintaining the quality and characteristic...

Inline powder analysis system

Ensuring quality and consistency in powder production is critical, especially in processes lik...

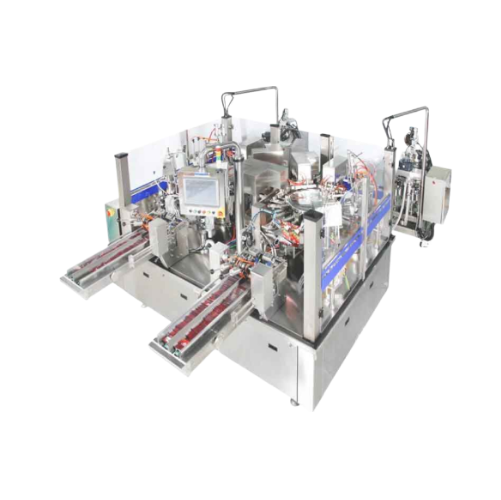

Automatic rotary premade pouch filler and sealer

In high-volume production environments, the need for efficient and compac...

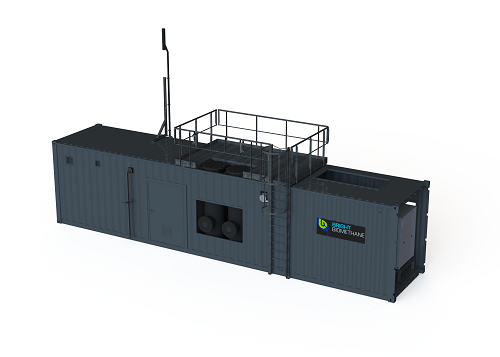

Spray drying system for nutritional powders

When producing high-quality nutritional powders, achieving flexibility in prod...

Sanitary separator for food processing applications

In food processing, maintaining high sanitary standards is crucial to...

Big bag filling machine

Active pharmaceutical ingredients demand high handling standards to prevent cross-contamination. More...

Manual bagger with net weigher

If you are looking for a weigher that is manually controlled for bagging, here it is. It has ...

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

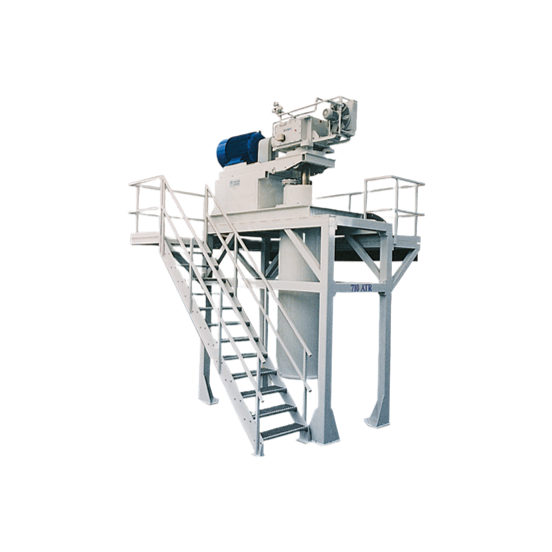

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Laboratory scale active freeze dryer

The laboratory-scale active freeze-drying is used for dehydrating high-value products ...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Checkweigher for sachets and sticks

The checkweighers for multiple lanes have a 1.5 times faster response speed and 2 times...

Fluid bed dryer for production scale

Fluidized bed drying (FBD) is a common process in the pharmaceutical industry for dryi...

Fluid bed dryer for lab scale

Fluidised bed drying (FBD) is a common process in the pharmaceutical industry for drying compo...

Fluid bed dryer and mixer for lab scale

Designed for pharmaceutical R&D, a lab-scale fluid bed dryer and mixer/granulat...

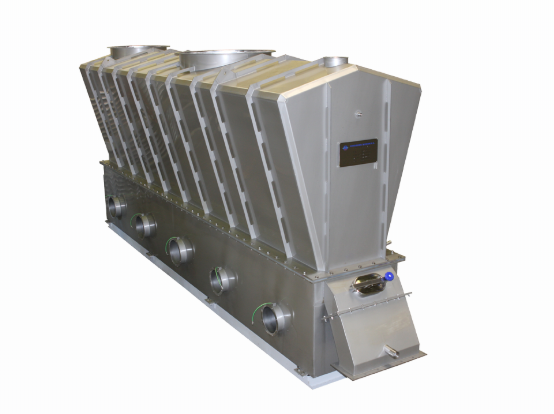

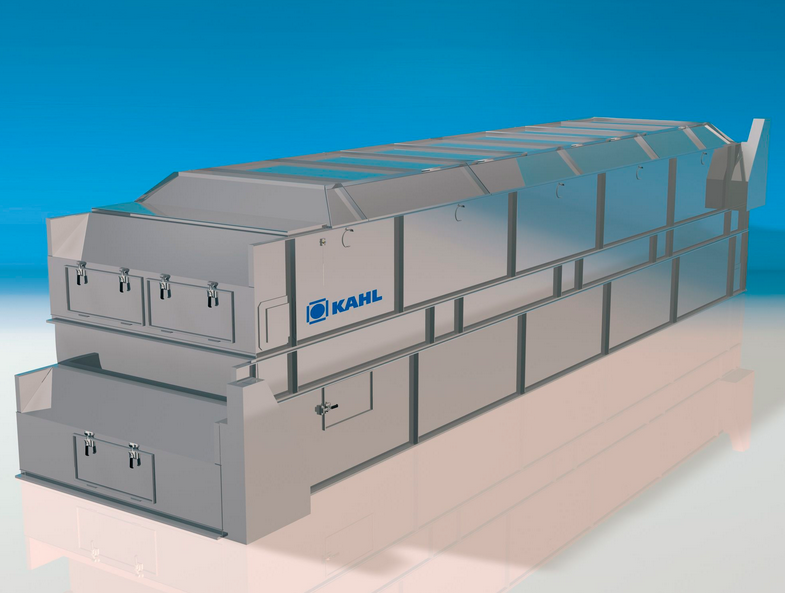

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...

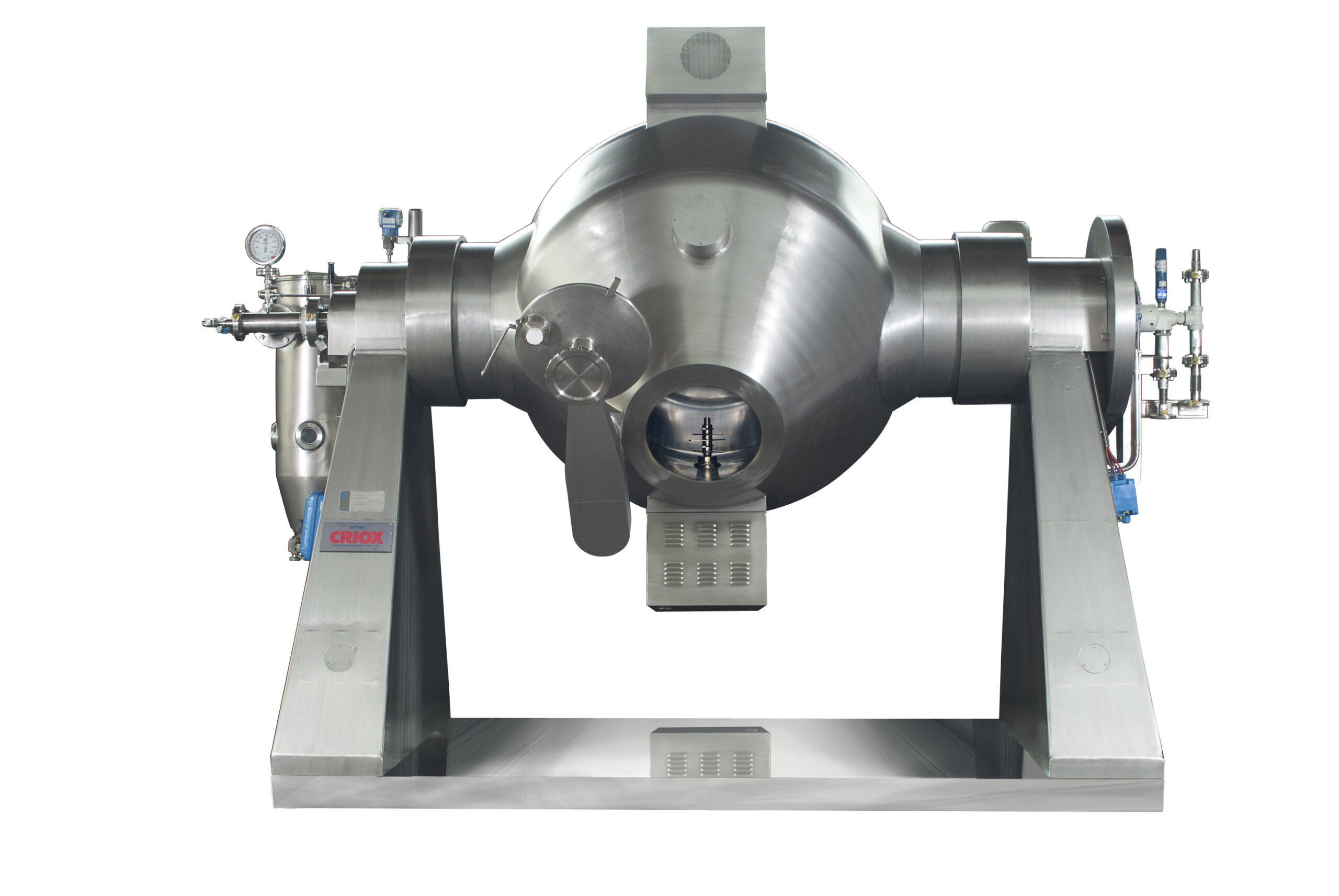

Rotary vacuum dryer

Powdered products tend to agglomerate during vacuum drying. This adds an additional step to the productio...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

Packaging machine for sealed plastic bags from 250 g to 10 kg

Sealing small quantities of solids or liquids into plastic...

Horizontal form, fill and seal machine for bags up to 10kg

Bagging small quantities of solids or liquids, whether in pap...

Horizontal vacuum dryer with eccentric agitator

Conventional dryers are inefficient and can lead to significant mechanical...

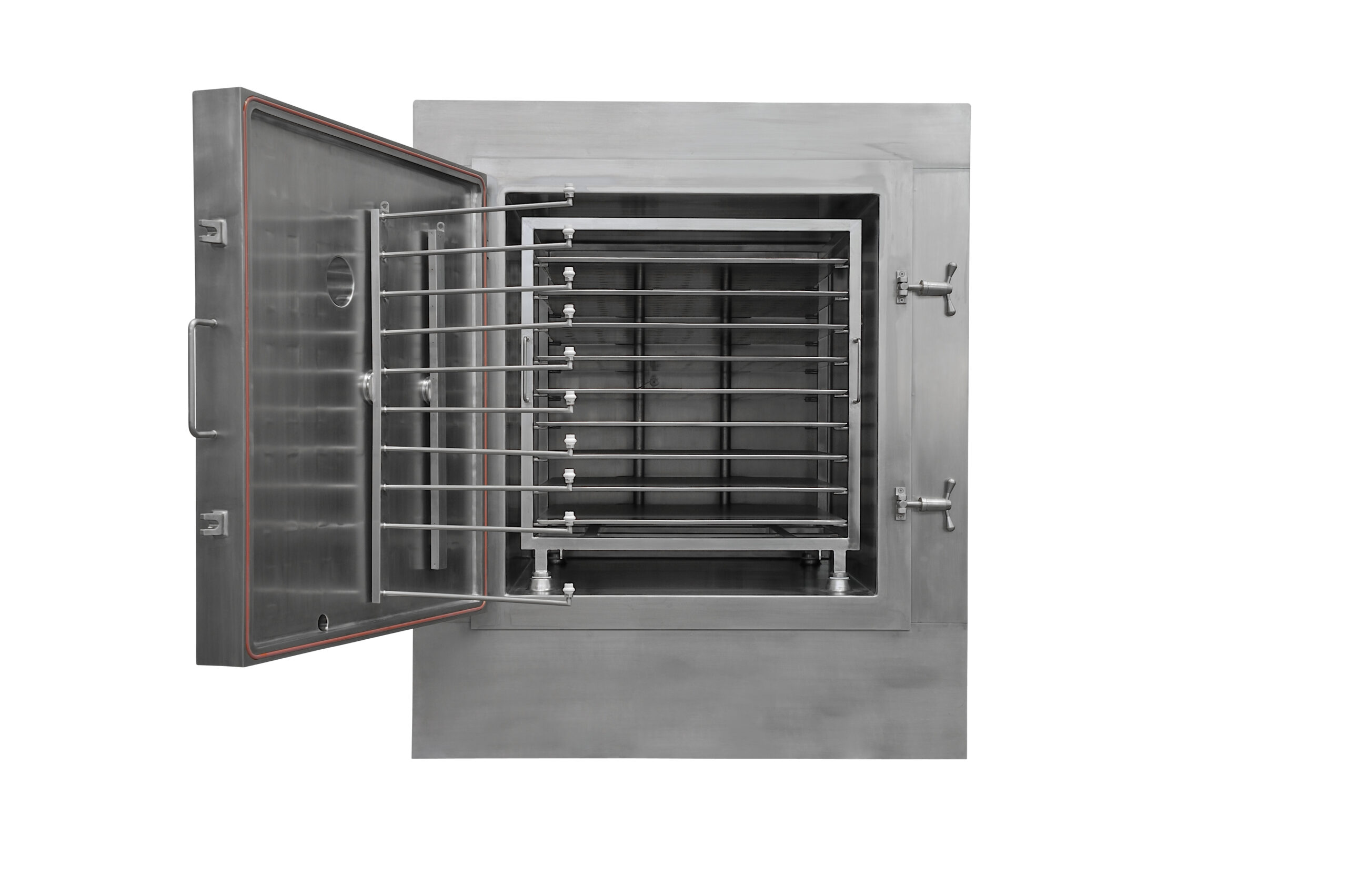

Vacuum tray dryer with clean-in-place system

Cabinet tray dryers can be difficult to clean, making their use difficult for...

Horizontal paddle vacuum dryer

Agitated vacuum dryers can be difficult to clean which makes them unsuitable for multi-produc...

Laboratory-scale vacuum tray drying oven

Vacuum drying is used to remove moisture from sensitive materials. Drying small ba...

Air dehumidifier for bulk products

When your product or process is sensitive to humidity, using an air dehumidifier may res...

Manual bagger with gross weigher

This is a manual bagging set with an electronic gross weighing system to meet international...

Checkweigher for stand-up pouches

When working with several lines of stand-up pouches, you can benefit from controlling the...

Belt dryer/cooler for pellets and granules

Many industries that process materials in pellet, powder, or crumble form need ...