Shampoo Making Equipment And Production

Find innovative production technology for making shampoo and connect directly with world-leading specialists

Shampoo is a unique form of cleaning agent composed primarily of water and some form of surfactant. This surfactant provides the ability to bind oily substances for removal without leaving a residue, as traditional soaps might. The production process involves the batch mixing of its laboratory-defined formula, quality control, and filling stages.

Stories about shampoo

Select your shampoo process

Tell us about your production challenge

Finding your perfect shampoo making formula

Apart from water and a primary surfactant, typically forms of lauryl sulfate, many other ingredients may be added to the shampoo making formula to provide additional desirable properties for scalp and hair care. Secondary surfactants, typically alkanolamides, may serve as foaming agents. Thickeners improve viscosity, conditioners offset the harshness of detergent surfactants, and preservatives ensure the longevity of the product. Finally, modifiers may adjust pH and opacity, and special additives as well as essential oils may be added for color, fragrance, or other distinguishing qualities.

Considerations of shampoo production equipment

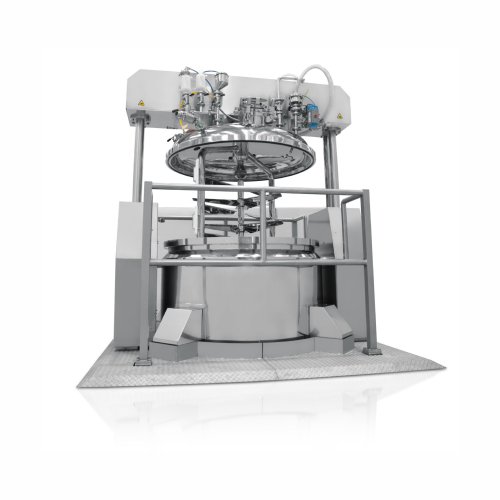

Once you have isolated your desired shampoo recipes, stability testing should be performed to ensure the final product undergoes minimal changes after bottling. You will typically look for physical changes in the color, odor, and texture of your shampoo. This is followed by batch production of the shampoo recipe in large tanks for thorough mixing. To do this, you may simply add ingredients to the tank where temperature and mixing speed may be modulated through computerized shampoo production and processing equipment to facilitate their combination. Following a quality control check, the process concludes with the bottling and packaging of your final product.

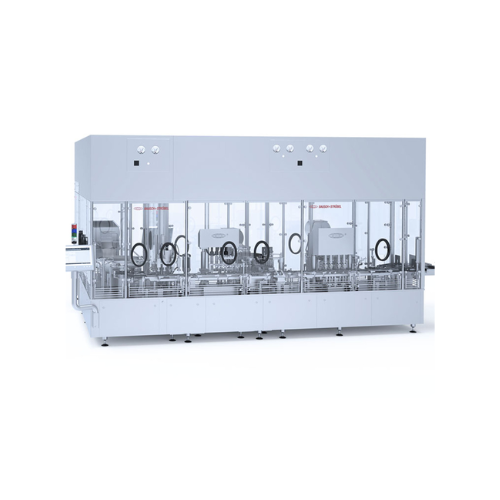

Bottling your liquid shampoo efficiently

This final step is the most involved part of the production process. Following acceptable quality control, you then pump your shampoo mixture from the batch tank into a holding tank for bottling. You first feed bottles upright into a hopper where they then move along a conveyor belt to the filling carousel. Here, calibrated pistons distribute precise quantities of shampoo to each bottle. You will also need to place caps into a hopper and, once correctly aligned, they are twisted tight by a capping machine. The bottles then proceed to labeling, which may be heat pressed or use adhesive labels. Finally, the labeled bottles exit the conveyor system and are ready to be boxed up for distribution.

Approaching the process of shampoo bar production

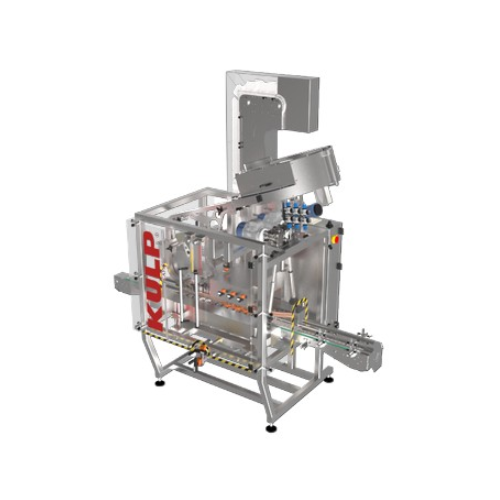

With the growth of the zero-waste movement and consumer conscientiousness, shampoo bars have become an increasingly popular alternative to traditional liquid shampoos. This process differs from the production of liquid solutions in that dry ingredients are combined by mechanical mixing in a hot or cold process, and a long continuous bar is extruded from the mixture. This bar is then cut to individual sizes and may be further customized by stamping and shaping. The final packaging process uses fewer materials for a more environmentally friendly production.

Packing your shampoo bars in boxes

Significantly simpler than packaging liquid shampoo, at its core, packaging your shampoo bars involves meeting your conveyor of individual bars with your conveyor of the desired packaging. After cutting and stamping, your shampoo bars move along a conveyor where they are picked up by a rotary packing machine. A separate machine prepares the boxes from their flattened pre-cut state into the form that will house your shampoo bars. Finally, the rotary packing machine distributes a bar into each box, and the occupied boxes may be further packaged for bulk distribution.

Variables in shampoo formulation

With the great variety of intended purposes, your shampoo formula may be tailored to suit different use cases. Pet shampoo, for example, commonly includes chlorhexidine and castile soap to provide antibacterial properties. Baby shampoo on the other hand requires gentler ingredients and may forgo colorants and scents entirely. Identifying the defining features of your use case is essential to producing an effective formula. Furthermore, some shampoo products contain natural ingredients such as coconut, essential oils and ginger just to name a few. These essential oils and natural ingredients are not only used for their pleasant smell. But, they are added for personal care as each provides unique benefits. For example, ginger in shampoo reduces itchy scalp and decreases dandruff when lathering and massaging your hair. Coconut oil is also used to leave your hair feeling fresh not matter your hair type.

Processing steps involved in shampoo making

Which shampoo technology do you need?

Gravimetric filling and capping system for chlorine solutions

Industries handling chlorinated or corrosive products face...

Pick & place robot for packing tubes in boxes

For manufacturers dealing with cosmetic products, efficiently packing filled...

Vacuum turboemulsifiers for liquid and creamy products

For large-scale production of liquid and creamy products, precise ...

Automatic tube filling and closing for metal, plastic, and laminate tubes

Efficiently handling various types of tubes,...

Volumetric filling system for cosmetic products

In the cosmetics industry, precise volumetric filling is imperative to mai...

Medium capacity filling line for food and cosmetics

In industries that handle food, cosmetics, or household products, eff...

Continuous inline capping system

In high-volume packaging operations, maintaining efficiency and consistency during the capp...

Volumetric filler for packaging liquids and semi-solids

In manufacturing and packaging, accurate filling of various liqui...

Positive displacement gear pump liquid filler

In manufacturing environments, precise liquid filling is essential for maint...

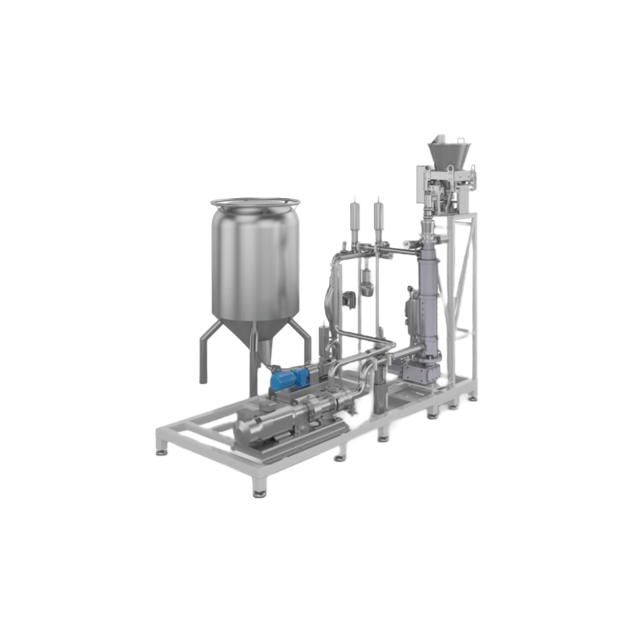

Inline system for personal care product production

When producing personal care products like ointments, lotions, or sham...

Filling and closing solution for plastic bottles

Producing pharmaceutical, cosmetic, or other liquid products often requir...

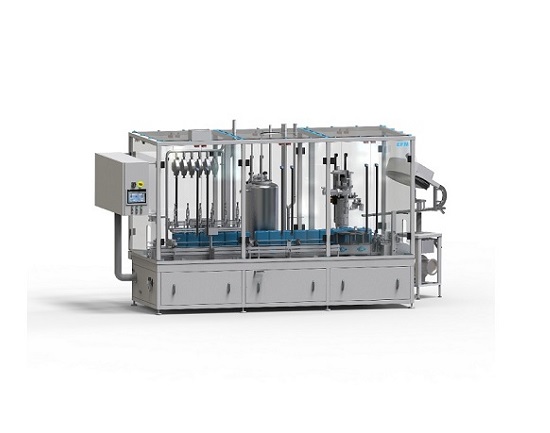

Automatic bottles and jars filling and capping line

In high-volume production environments for cosmetics, pharmaceuticals...

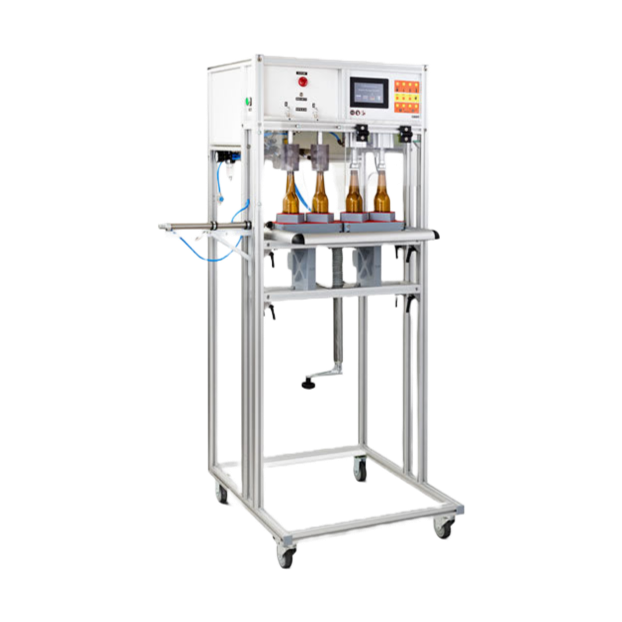

Automatic detergent shampoo filling solution

In the production of daily chemical products such as detergents and shampoos,...

Compact wraparound labelling system for bottles

For industries requiring swift and reliable labelling on cylindrical conta...

High precision three-roller wraparound labeller

For small to medium enterprises needing consistent vertical placement and ...

Rotary filler capper for personal care products

In the personal care industry, ensuring consistent filling and capping of ...

Soap bar fold wrapping solution

In the soap manufacturing industry, consistent and efficient packaging is essential to maint...

Tamper evident banding system

To ensure product authenticity and consumer safety tamper-evident packaging can be necessary.

Automatic timed flow volumetric filling machine

When handling diverse packaging needs such as water-thin liquids to light ...

Semi-automatic pressure sensitive labeling system

In industries where precise and flexible labeling is crucial, manual la...

Automated snap capper for various container types

In industrial packaging, manual placement of snap caps can lead to repe...

Indexed stomp capper for continuous bottle capping

In high-volume bottling operations, manually placing and pressing snap...

Volumetric piston fillers for liquid and dense products

When packaging liquids or dense products like creams and viscous ...

Injection stretch-blow molding system for Pet containers

In the production of PET containers, especially in smaller lots,...

Manual plastic tube sealing equipment

Working in labs or with small batch production lines where you have to seal plastic o...

Monobloc filler and capper

If you have separate filling and capping stations you may experience lower throughput rates due t...

GMP homogenizing system

Manufacturers need production mixing equipment that is capable, flexible, and easy to maintain. Accur...

Small-scale laboratory dispersing machine

Developing and validating new processes requires reliable and highly versatile e...

Bottle filling and capping monobloc

Spillage and overfilling are common problems in most production lines for bottled produ...

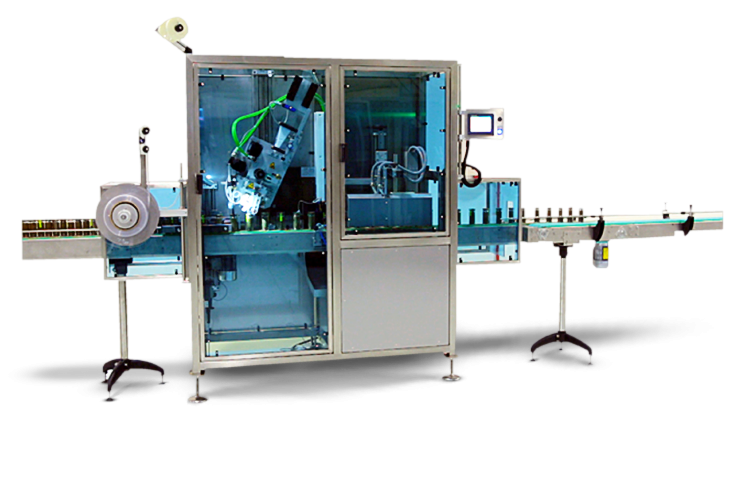

Shrink sleeve labeling machine

Shrink sleeves are new type of full-colour labels that give the opportunity to create a 360-d...

Steam tunnel for shrink sleeve labels

When it comes to the option of applying sleeves or film on a container without wrinkl...

Hot air tunnel for shrink sleeve labels

Sleeves are very popular in food, beverage, Chemical and pharmaceutical industry be...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

In-line monoblock linear filler & capper

In many food, chemicals and cosmetic industry processes it is vital to have a...

Flowmeter filler

For larger production runs of food, non-food and cosmetics industries, where accuracy and volume of filling i...

Colloid mill

For creating extremely fine emulsions and high quality dispersions a high pressure homogenizer is often chosen. ...

High-pressure homogenizer

When processes call for homogenized emulsions with extremely fine particle sizes the traditional t...

Compact monoblock filler

Filling and capping bottles and pots for food, chemical and cosmetics industries using separate mach...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Single head capper

For the stand-alone capping of bottles of up to 30 litre capacity for smaller-scale production you need a ...

Servo controlled filler

For food and non-food liquid products that are high foam or have a high viscosity a specialist fillin...

Multi-head capper

For the stand-alone capping of bottles of up to 2.5litre capacity you need a robust and flexible machine wi...

Shrink sleeve applicator - 400 per minute

Flexible medium to high speed application of shrink sleeveing to containers is u...

Compact shrink sleeve applicator

Adding tamper prevention to product packaging can be expensive and difficult to set up. Thi...

Electric shrink tunnel solution

Adapting shrink sleeve heating tunnels for different applications can be a lengthy and expen...

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Dispersing machine for emulsions and suspensions

Equipment operating under the rotor/stator principal is often employed wh...

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Dispersing machine for very fine emulsions and suspensions

For continuous high performance mixing of solid and liquid ra...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Batch dispersing machine

Equipment operating under the rotor/stator principal is often employed when more traditional methods...

Batch dispersing machine for abrasive products

For mixing and dispersing tasks that cannot be completed by conventional st...

Batch dispersing machine for bottom entry into vessels

When your process requires high performance mixing or dispersion b...

Lid applicator for corrugated cases

For your secondary packaging, you may be considering packing into boxes that require a ...

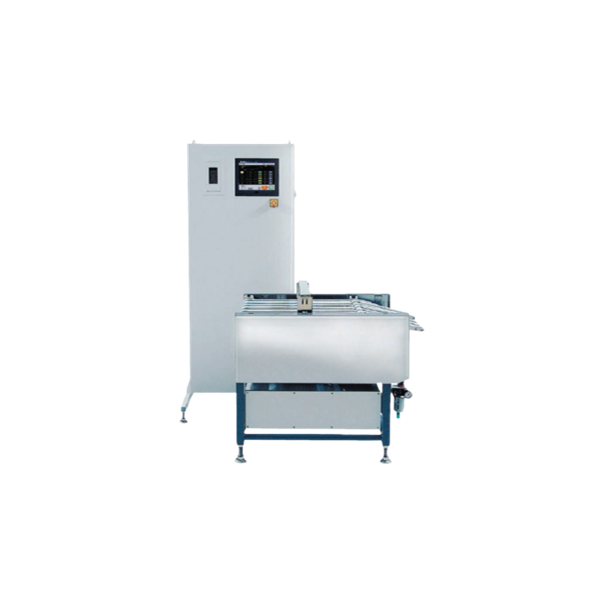

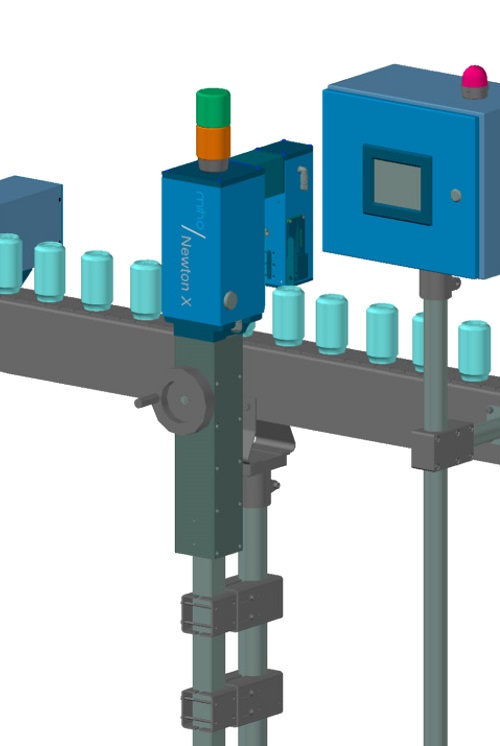

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

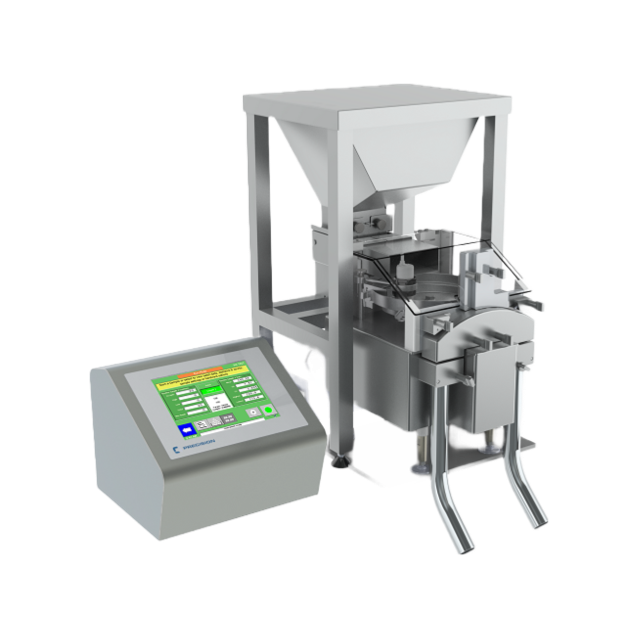

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Residual liquid inspection system

Inspection system that eliminates the risk of residual liquid, water or left over drink i...