Making Soybean Meal

Find innovative production technology for making soybean meal and connect directly with world-leading specialists

Only about 6% of the soy produced globally is directly consumed by humans, typically as edamame beans, tofu, or soy milk. More than three-fourths of global soy production goes to animal feed. The rest is processed by soybean meal technology into oils or used for biofuels and other industrial processes.

Select your soybean meal process

Tell us about your production challenge

Getting rid of soybean anti-nutrients

Soybeans have proteins and fat that make them great for human and animal consumption. But they also have some anti-nutrients that can be harmful to health. Soybean meal technology employs two main methods to reduce these anti-nutrients.

You can use a slow industrial cooker. Here soybeans will pass through chambers heated at different temperatures. This way, you get rid of the anti-nutrients. Moreover, the bean will be preserved, and its amino acids, fat, and proteins.

On the other hand, you can use an extruder. The anti-nutrients will be inhibited in a short time with a high temperature. Consequently, you will get a full-fat soy meal, which you can pass through a press to extract the oil and get soy cake.

Leverage soybean meal technology for plant-based meat products

Whether full fat, low fat, or defatted, most soybean meal products used for human consumption need further processing, such as extra milling and drying.

Although the majority of soy meal is used for animal feed, industrial production forms a critical part of plant-based trends in novel foods. You can make soy protein shakes, soy flour, soy patty burgers, sausages, and even bacon.

In addition, there are many ongoing types of research for future development and uses of soybean production for industrial uses. For example, the extracted soy oil can be used as building materials, biodiesel, lubricants, and even soy-based tires.

Are soy production and soybean meal consumption coming to an end?

Soy production and consumption increased in the world. The demand for cropland expansion for soy plantations has increased as well. Soy is one of the biggest causes of deforestation. As well as its side effects of biodiversity loss, soil erosion, carbon emissions, and water contamination.

The demand for soybean meal production to feed livestock can be replaced with alternative proteins. If alternatives such insect-protein are used, then not extra land will be needed. Soy production can continue to exist if soybeans would be cultivated in a sustainable way. And land used for soy aimed at animal feed would be reforested.

Processing steps involved in soybean meal making

Which soybean meal technology do you need?

Screw press for mechanical oil extraction

High demand for feed in the animal husbandry sector necessitates efficient proce...

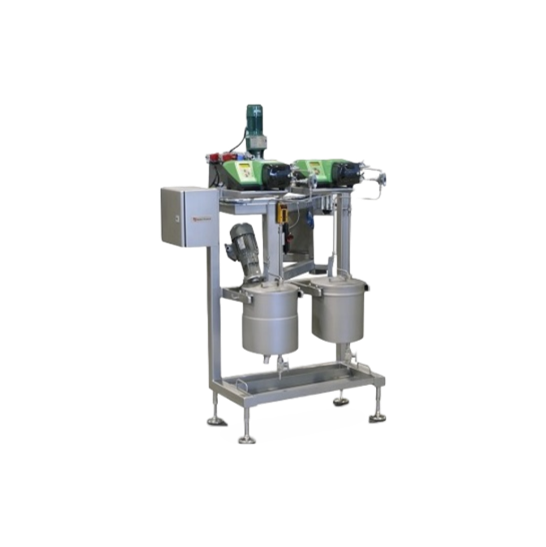

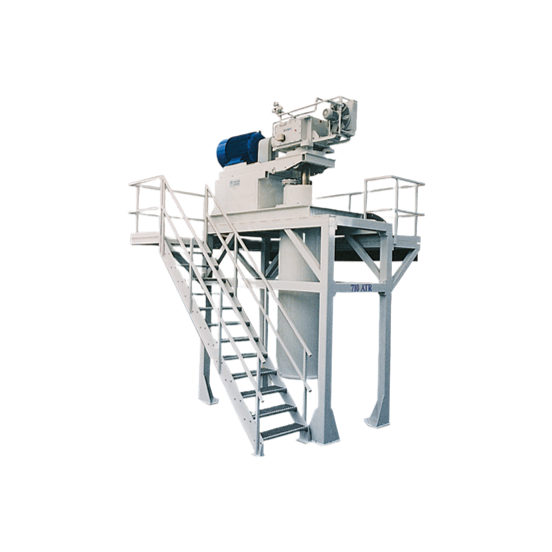

Vertical seed conditioning system for oil extraction

When preparing seeds for oil extraction, it’s vital to heat an...

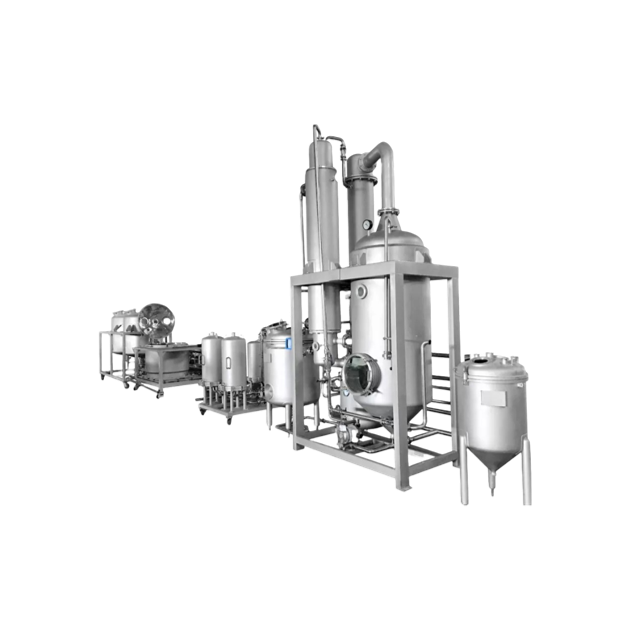

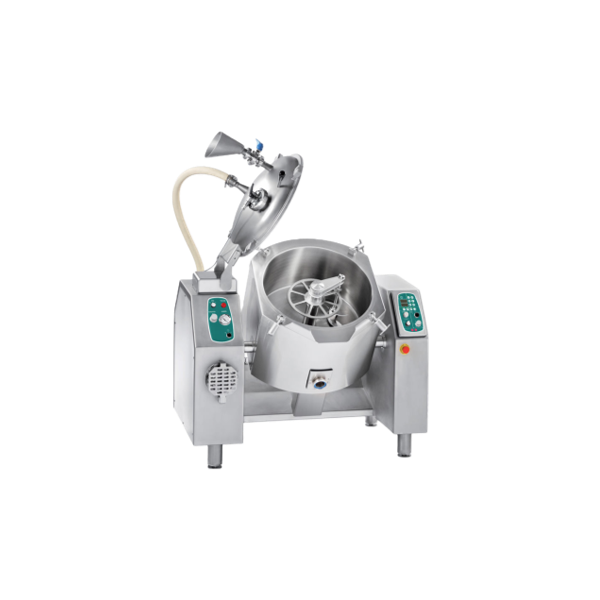

Efficient desolventization and toasting solution for oilseeds

In the processing of oilseeds, such as soybeans and canola...

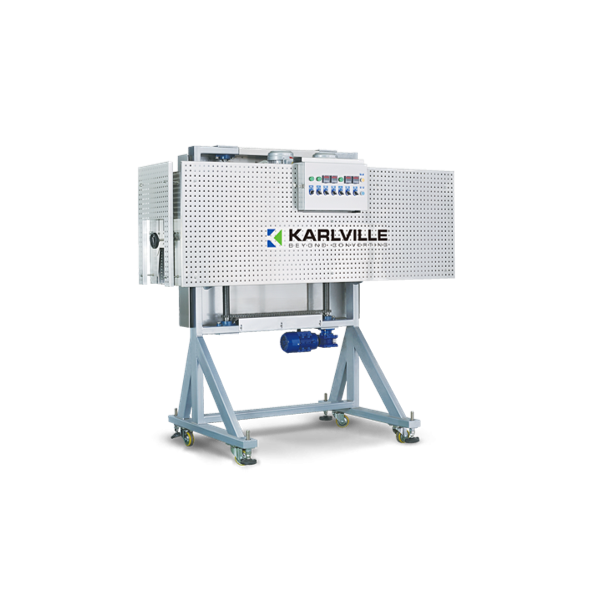

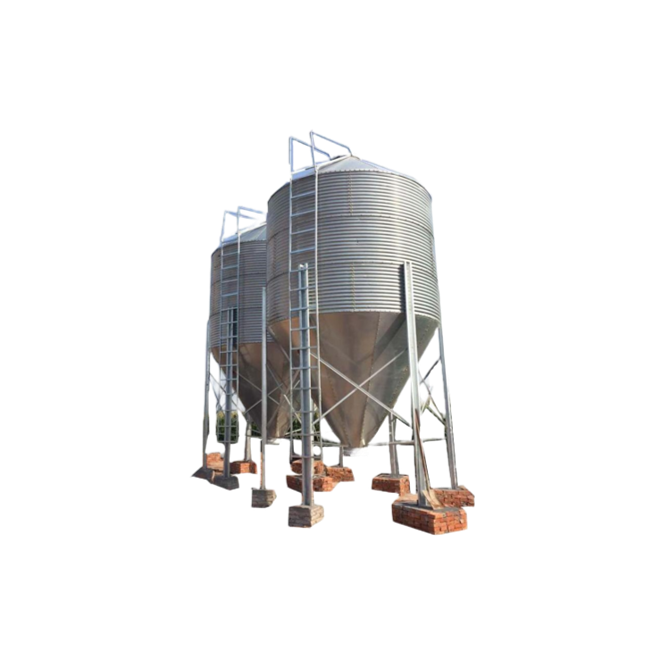

Seed conditioning system for soybeans and rapeseed

When processing soybeans or rapeseed, effective seed conditioning is c...

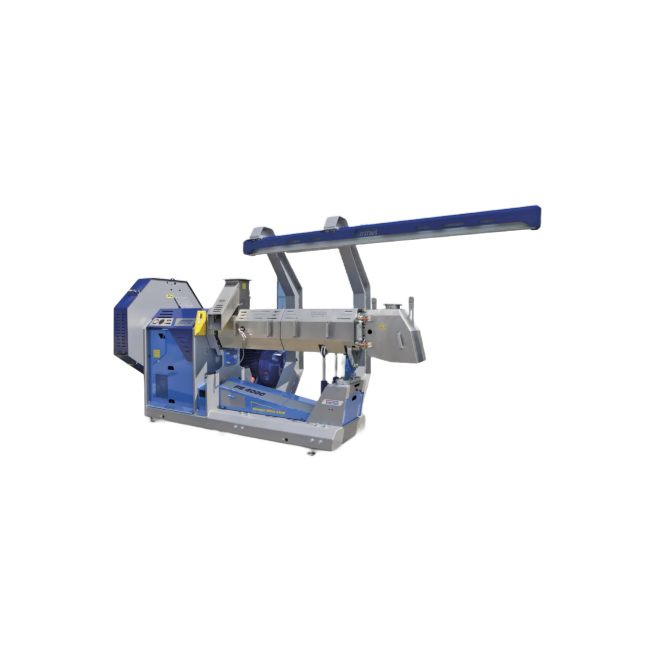

Cracking mill for oilseeds and feed

In the oilseed and feed industry, the challenge of optimizing throughput while maintain...

Soybean dehulling separator

In soybean processing, separating hulls from broken kernels after each cracking stage is crucial...

Cracking mill for oilseeds and feed processing

Efficient processing of oilseeds and feed requires a reliable and high-perf...

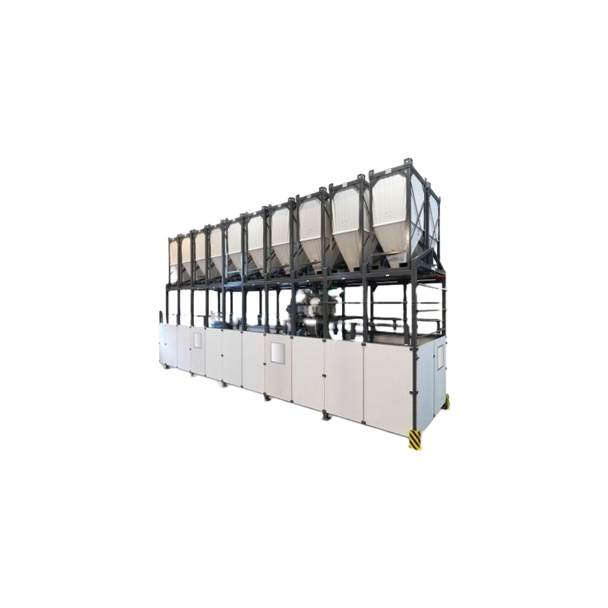

Oilseeds preparation plant

When producing customized flakes, pressed cakes, or other oilseed products, the oilseed preparati...

Organic soybean feed extruder

Soybeans are an essential ingredient in the creation of protein-rich animal feed. To achieve h...

Automatic palletizer machine for bags and boxes

The effective placement and positioning of bags and boxes can be a challen...

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

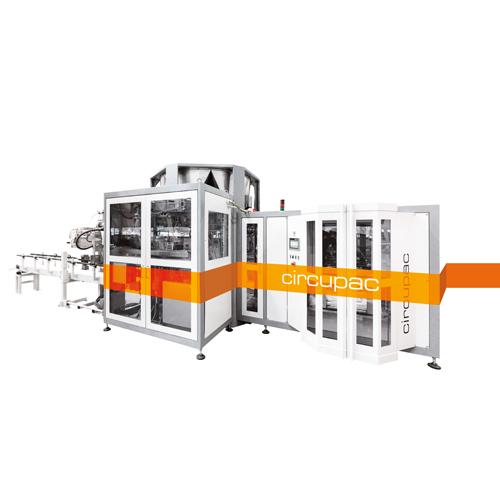

Form fill seal bagging machine

If you are in industries such as petrochemicals, fertilizers, animal feed, food, etc, you mus...

Vertical form fill seal machine

There is an increasing demand for a range of different package sizes of the same product. If...

Robot palletizing system

If you are a relatively large-scale producer, packing and transporting large quantities of products ...

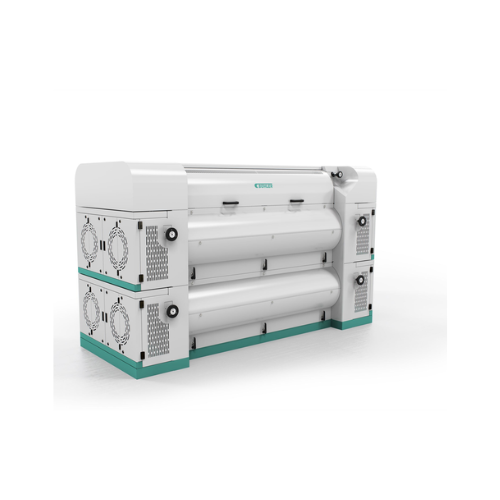

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

Feeder with flexible wall hopper

The varying properties of dry powder products mean that specialized feeders are required fo...

Stretch pallet hooder

Palletised loads need to be securely wrapped in order to protect them from shifting, crushing, ripped o...

Rotary bag packers for valve bags

Quick filling of bags while avoiding leakage out of the top of a bag can be challenging o...

High-capacity bulk weighers

A checking weigher recognized for receiving and shipping bulk materials, typically in mills and ...

Air dehumidifier for bulk products

When your product or process is sensitive to humidity, using an air dehumidifier may res...

Compact palletizer

Choosing an accurate palletizer can be quite an advantageous move. This one is designed for euro, industri...