Empty bottle inspection

Connect directly with world-leading production technology suppliers of innovative empty bottle inspection

Empty bottle inspection equipment can help ensure the safety and quality of a bottle-filling operation. Bottles may need to be inspected for variation in size, shape, and color, for the presence of foreign objects, for breakage, or for the presence of residual liquid. The bottle finish, capping-thread, inner and outer sidewalls, may also require an inspection to ensure compliance with quality standards. Considerations for selecting the right equipment include the size, shape, and material of the bottles, production speed, and other relevant inspection parameters. Bottle inspection equipment is widely used in the food industry to ensure compliance with quality control procedures. In the pharmaceutical industry vial, ampoules and bottles are inspected to ensure product safety.

What are you making?

Which empty bottle inspection technology do you need?

X-ray assisted empty bottle inspection

In beverage production, ensuring that empty bottles are free from defects and contam...

Empty bottle inspection for beverages

In the beverage industry, ensuring that empty bottles are free from contamination and...

Empty bottle inspection system for food industry

In the food production process, ensuring that bottles are free from conta...

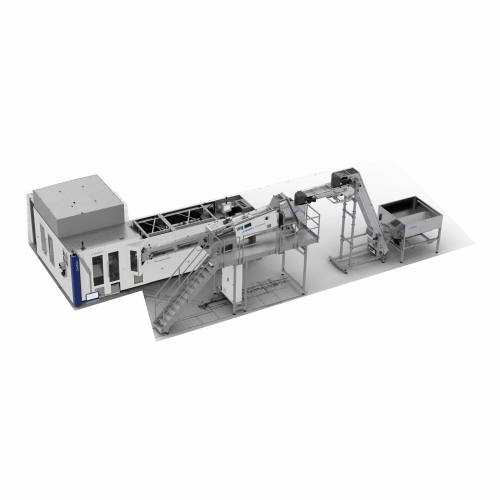

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Preform and container inspection system

Maintaining the quality of both preforms and blow-moulded bottles is crucial for ef...

Bottle inspection system for foreign particles detection

In beverage production, ensuring that each container is free fro...

Empty capsule sorting system

In pharmaceutical production, ensuring the quality and consistency of capsules is critical. Def...

Empty container inspection for pharma packaging

In the pharmaceutical industry, ensuring the integrity of primary packagin...

X-ray assisted empty container inspection system

In the food, beverage, and pharmaceutical industries, ensuring the integr...

Empty crate inspection system

In the beverage, food, and pharma industries, ensuring that empty crates are free from defects...

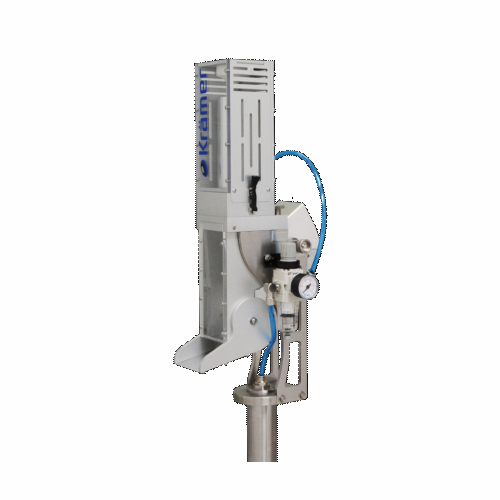

Empty bottle inspector for beverage industry

In beverage production, ensuring the integrity of empty bottles before fillin...

Empty can inspection system for defect detection

In high-speed beverage production lines, undetected defects in empty cans...

Empty can inspection system for beverage industry

Ensuring the integrity of beverage cans before filling is crucial to ma...

Automatic mineral water filling system

In the production of bottled mineral water, the need for a reliable and efficient fi...

5 gallon water filling system

In industries where large quantities of drinking water need to be packaged efficiently, ensuri...

Dual view x-ray inspection for canned goods

In food manufacturing, ensuring the absence of foreign bodies in products pack...

Leak testing system for aerosol cans

Ensuring the integrity of pressurized aerosol cans is critical for safety and complian...

High capacity automatic blister packaging system

For industries involved in pharmaceutical and cosmetic manufacturing, eff...

Advanced residual liquid inspection system

Advanced and easy to use inspection system that eliminates the risk of residual...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...

Empty bottle height sorting system

An empty bottle sorting system that uses the light barrier technology. It detects bottle...