Industrial jet mills

Connect directly with world-leading production technology suppliers of innovative industrial jet mills

A jet mill uses high-speed jets of compressed air/ inert gas to impact particles into each other, breaking them down, as they spiral around in a vortex. The mill can be configured to emit particles below a certain size which leads to narrow particle size distribution in the ground product. Jet mills find applications in the production of pharmaceutical active ingredients and fine-grade chemicals. They are suitable for contamination-free grinding of heat-sensitive materials such as toner, dyestuffs, fluorescent powders, silica, special metals, and ceramic raw materials.

What are you making?

Which industrial jet mills technology do you need?

Fluidised bed opposed jet mill for ultrafine powder production

In many industries, producing powders with a precise and ...

Corn masa preparation system

In high-volume tortilla and corn chip production, traditional masa preparation methods often le...

Particle sizing solution for milling and sifting

In pharmaceutical and food processing, efficient particle sizing is essen...

Micronization for pharmaceuticals

In pharmaceutical manufacturing, achieving precise particle size is critical for effectiv...

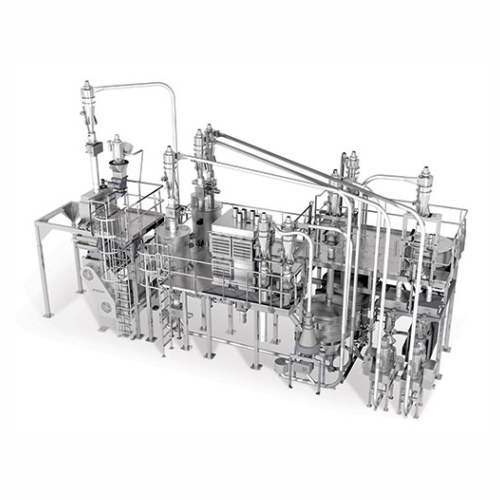

Production scale jet mill

Large volume manufacturers demand the most out of their production process, including powder milli...

Jet mill micronizer

Small scale manufacturers that require effective micronization of powders for their process lines may nee...

Pilot scale jet mill

In a pilot scale level or preliminary study, all the production process steps have to satisfy the small ...

Laboratory jet mill

Manufacturing small quantities of high-value products requires efficient machines that can process these ...

Jet mill for clinical trials

R&D laboratories may need to reduce the size of powder particles in small quantities for cl...