Detergent Manufacturing Equipment

Find innovative detergents equipment and connect directly with world-leading technology suppliers

Detergents are cleaning agents that help remove dirt and grease from porous and non-porous surfaces. Industrial production of detergents began after World War I. Still, it was after the 1950s and 1960s that the detergent industry grew exponentially due in part to the development of new detergent manufacturing equipment.

Innovative technologies for producing detergents

Liquid detergent filling machine

Filling of liquid detergents requires specialised equipment because of the foaming nature o...

Automatic detergent shampoo filling solution

In the production of daily chemical products such as detergents and shampoos,...

Hand sanitizer capping machine

Bottled products such as hand sanitizers, shampoos, and liquid detergents, have different cap...

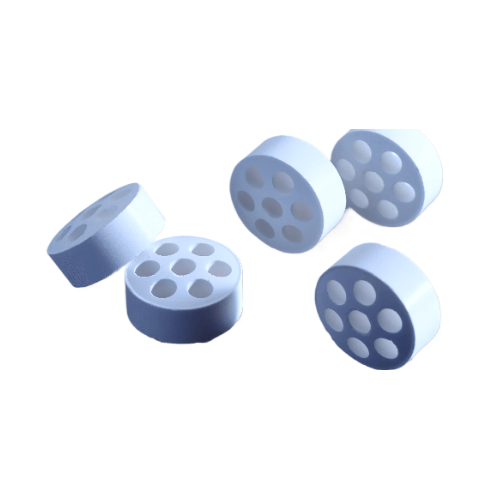

Three-layer dishwasher tablet press

Dishwasher detergent tablets come either in a single layer or multi-layer form. Multi-l...

Select your detergents process

What are you making?

Tell us about your production challenge

Dirty substances are generally related to hydrophobic fatty materials insoluble in water. However, detergents are amphiphilic, meaning they contain both non-polar hydrophobic (water-hating) and polar hydrophilic (water-loving) ends. This dual nature allows the detergent to grab the oily-greasy dirt stains and wash them away.

As surfactants or a mixture of surfactants, detergents have the ability to decrease the surface tension of water. This function facilitates the formation of dispersions, emulsions, and suspensions.

The most common detergent is soap, a sodium salt of fatty acids. To increase solubility, modern detergents contain alkyl-benzene sulfonates. In fact, these compounds (polar sulfonate group) are more soluble in hard water than soap (polar carboxylate group). Polar sulfonate is less likely to bind to calcium and other ions of the hard water than polar carboxylate.

Detergent manufacturing process

Detergent manufacturing involves mixing the raw materials in large tanks; the manufacturing process can be batch as well as continuous. Raw materials are selected based on the form and properties of the desired end product. It is essential to mix all ingredients thoroughly in a mixer machine to ensure that the chemicals are evenly distributed in the detergent.

Fillers, surfactants, disinfectant agents, and chemical agents are used as ingredients in detergent making. To give color, powdered pigments can be added. In hand soap production, for example, adding a preservative is critical to prevent the proliferation of bacteria if the soap is exposed to a substandard environment.

Liquid detergent, powder detergent, or laundry detergent?

Historically, when people referred to detergent, they usually indicated laundry detergent. It was only after the 20th century, due to the development of detergent making equipment, that the word detergent acquired a broader meaning with its liquid and powder form.

Laundry detergent

Wash, dry, fold, repeat. This is the daily formula for doing laundry. Helping us in this daily task is detergent which has a slightly different formula.

Producers can use three methods when making laundry detergent: dry mixing, agglomeration, or spray drying. The spry drying technique is the most used because it produces a lightweight, well-hydrated product that doesn’t cake. Pay attention to the pH range when producing the washing powder; the pH has to be 9-10.5. to ensure it is compatible with human skin and can clean effectively.

Powder vs. liquid detergent

The ingredients that make up powder detergents are builders, surfactants, and enzymes. This detergent is mainly used as a laundry detergent and is a more affordable choice because containing no water is lighter than liquid detergent, meaning that it has lower transportation costs. Powder detergent can be made by the agglomeration method and can be easily recognized by its granule-like appearance; however, the spry drying method is widely used in the detergent industry because it simplifies the process and improves the profit margin by turning a slurry into a dried powder in a single step.

Liquid detergents are nothing more than powders mixed with water and chemical solutions called solubilizers, making detergents dissolvable in water.

…And what about dishwasher tablets?

Dishwasher tablets are essential to make your dishes shine. The dishwasher tablet production always starts by obtaining granular detergent additives from a spray-dried slurry – Did we already mention that the spray-drying method is everywhere in the detergent making process?

After combining the granules with builders, water, surfactant, bleaching agent, dye, and fragrance, producers transfer it to a hydraulic or rotary press for the tableting process.

Packing your detergent products

When it comes to detergents, the packaging process depends on whether the detergent comes in liquid or powder form. For liquid detergents, a filling system pumps the liquid product into plastic bottles where a weighing device controls the correct filling level. After filling, a capping machine seals the bottles. For powder detergent, the packaging process begins by creating the bag or the pouch from a flat carton or laminated film. Then the selected container will be filled with powder detergent and sealed.

Detergent making videos

Detergent filling machine

Detergent capping machine

Which detergents technology do you need?

Automatic detergent shampoo filling solution

In the production of daily chemical products such as detergents and shampoos,...

Liquid detergent filling machine

Filling of liquid detergents requires specialised equipment because of the foaming nature o...

High efficiency milling solution for pharma and food industries

In numerous pharmaceutical and food industry application...

Double cone blender for homogeneous solid-solid mixtures

In manufacturing processes within the pharmaceutical, food, and ...

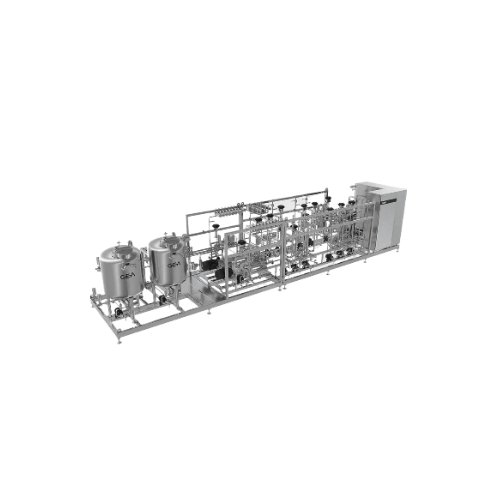

Automated system for cleaning in place (cip)

In industries where food and beverages are processed, maintaining hygiene and...

In-line filling system for pharmaceutical products

In many pharmaceutical applications, complete control over packaging p...

High impact mixer for powders and liquids

In industries requiring highly homogeneous mixtures of powders and liquids, achi...

Production system for multi-chamber portion packs

In the manufacturing of customer care and medical products, precise fil...

Automatic edible oil filling & capping solution

Manufacturers in the food, cosmetics, and chemical industries often face t...

Rotary tablet press for large volume industrial tablets

In industries requiring high-volume tablet production, manual or ...

Continuous in-line blender for home and personal care products

In the home and personal care industry, manufacturers fac...

Cip for pharmaceutical process plants

In pharmaceutical manufacturing, precision cleaning is crucial to avoid cross-contami...

Rotary piston fillers for pumpable products

In the food industry, filling containers with pumpable products requires preci...

Stand-up pouch filling and sealing system

In industries such as food, dairy, and personal care, there is a need for effici...

Horizontal flat pouching for top-cap pouches

When manufacturing various food, beverage, and personal care products, effici...

Accurate pharmaceutical dispenser for high-viscosity fluids

In pharmaceutical production, precise dosing of high-viscosi...

Hyper-clean electronic volumetric filler for Pet bottles

Maintaining hygiene and precision in the filling process is cruc...

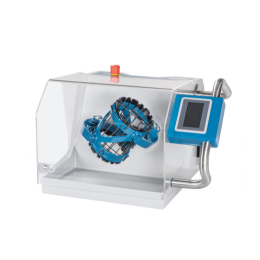

Fully automated dishwasher tablet press

The process of making dishwasher tablets that have more than one layer is very deli...

Hand sanitizer capping machine

Bottled products such as hand sanitizers, shampoos, and liquid detergents, have different cap...

Three-layer dishwasher tablet press

Dishwasher detergent tablets come either in a single layer or multi-layer form. Multi-l...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

Pelleting press with overhead drive

Production of certain pelletized products requires working with output products of a pa...

Self-cleaning filter for industrial and hygienic applications

Industries such as paint, food processing, and waste water...

Pressure monitoring solution for dosing processes

Accurate pressure monitoring is critical in dosing applications especia...

Single feeder operator interface for gravimetric feeders

In industries requiring precise material dosing, managing a grav...

R&D shaker mixer for battery powders and chemicals

Material heterogeneity, agglomeration, and contamination are key param...

Eccentric press for refill tablets

Hundreds of different refill tablets, of various shapes or sizes, are on the market toda...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Micro powder dosing system

Micro dosing of powders and small components can be a major obstruction in the production process...

Automatic bottle capping machine

Traditional bottle capping systems are inflexible, limiting the scope of your packaging and...

Air knife drying system for containers

In food or beverage production where a product is filled into jars, there is often r...

Semi-automatic trigger capping machine

Trigger spray bottle are the ideal capping solution for many chemical and household ...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

Air rinsing system for containers

Traditional water rinsing solutions for containers used in the food and pharmaceutical se...

Shrink sleeve applicator - 400 per minute

Flexible medium to high speed application of shrink sleeveing to containers is u...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...

Energy efficient tunnel for sleeve application

Hot air application of shrink sleeves is much more efficient than tradition...